A kind of epoxy composite material and preparation method thereof

A composite material and epoxy technology, which is applied in the field of thermally conductive insulating materials, can solve problems such as difficulty in meeting anti-cracking performance requirements, complex preparation procedures, etc., and achieve the effects of reducing material cost, simple preparation method and increasing filling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

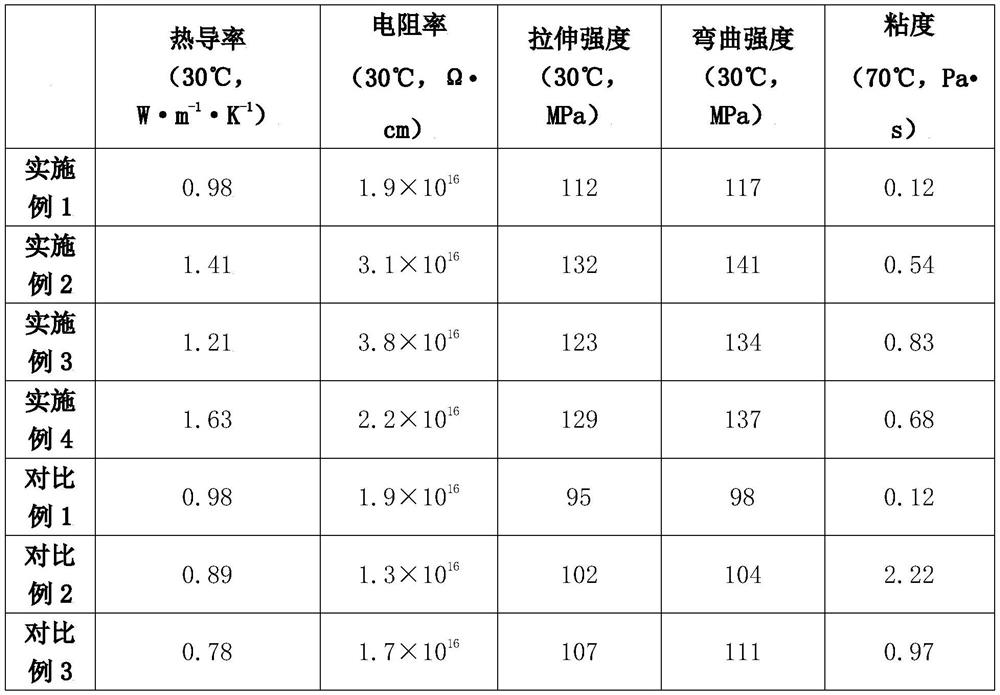

Examples

Embodiment 1

[0028] This embodiment provides an epoxy composite material, the raw materials include epoxy resin binder, inorganic filler, curing agent and fiber fabric; wherein the epoxy resin binder is bisphenol A epoxy resin, and the inorganic filler is boron nitride , the curing agent is phthalic anhydride, and the fiber fabric is aramid fiber fabric. The inorganic filler is composed of two kinds of boron nitride fillers with different particle sizes. The ratio of the average particle size of the large particle size filler to the small particle size filler is 1:0.4, and the average particle size of the large particle size filler is 250 μm. . In terms of volume percentage, the inorganic fillers accounted for 30% of the epoxy composite material, wherein the filler with large particle size accounted for 16.3% of the epoxy composite material, and the filler with small particle size accounted for 13.7% of the epoxy composite material.

[0029] This embodiment also provides one or more prepa...

Embodiment 2

[0031] This embodiment provides an epoxy composite material, the raw materials include epoxy resin binder, inorganic filler, curing agent and fiber fabric; wherein the epoxy resin binder is hydrogenated bisphenol A epoxy resin, and the inorganic filler is boron nitride , silicon nitride and silicon oxide in a mass ratio of 1:1:2, the curing agent is hexahydrophthalic anhydride, and the fiber fabric is a mixed fabric of aramid fiber and polyimide fiber. The inorganic filler is composed of two kinds of fillers with different particle sizes. The ratio of the average particle size of the large particle size filler to the small particle size filler is 1:0.412, and the average particle size of the large particle size filler is 18 μm. In terms of volume percentage, inorganic fillers account for 40% of the epoxy composite material, wherein the filler with large particle size accounts for 22.5% of the epoxy composite material, and the filler with small particle size accounts for 17.5% o...

Embodiment 3

[0034] This embodiment provides an epoxy composite material, the raw materials include epoxy resin binder, inorganic filler, curing agent and fiber fabric; wherein the epoxy resin binder is bisphenol F epoxy resin, and the inorganic filler is boron nitride, A mixture of aluminum nitride and silicon nitride in a mass ratio of 3:5:1, the curing agent is methyltetrahydrophthalic anhydride, and the fiber fabric is a mixed fabric of glass fiber and basalt fiber. The inorganic filler is composed of two kinds of fillers with different particle sizes. The ratio of the average particle size of the filler with a large particle size to that of the filler with a small particle size is 1:0.37, and the average particle size of the filler with a large particle size is 10 μm. In terms of volume percentage, inorganic fillers account for 37% of the epoxy composite material, among which, the filler with large particle size accounts for 20.6% of the epoxy composite material, and the filler with sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com