Preparation method of high-strength and high-thermal-conductivity carbon nanotube reinforced magnesium-based composite material

A carbon nanotube and composite material technology, applied in the field of magnesium-based composite material preparation, can solve the problems of high strength and high thermal conductivity, high cost, high alloy density, etc., to achieve tight combination, short process and low density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

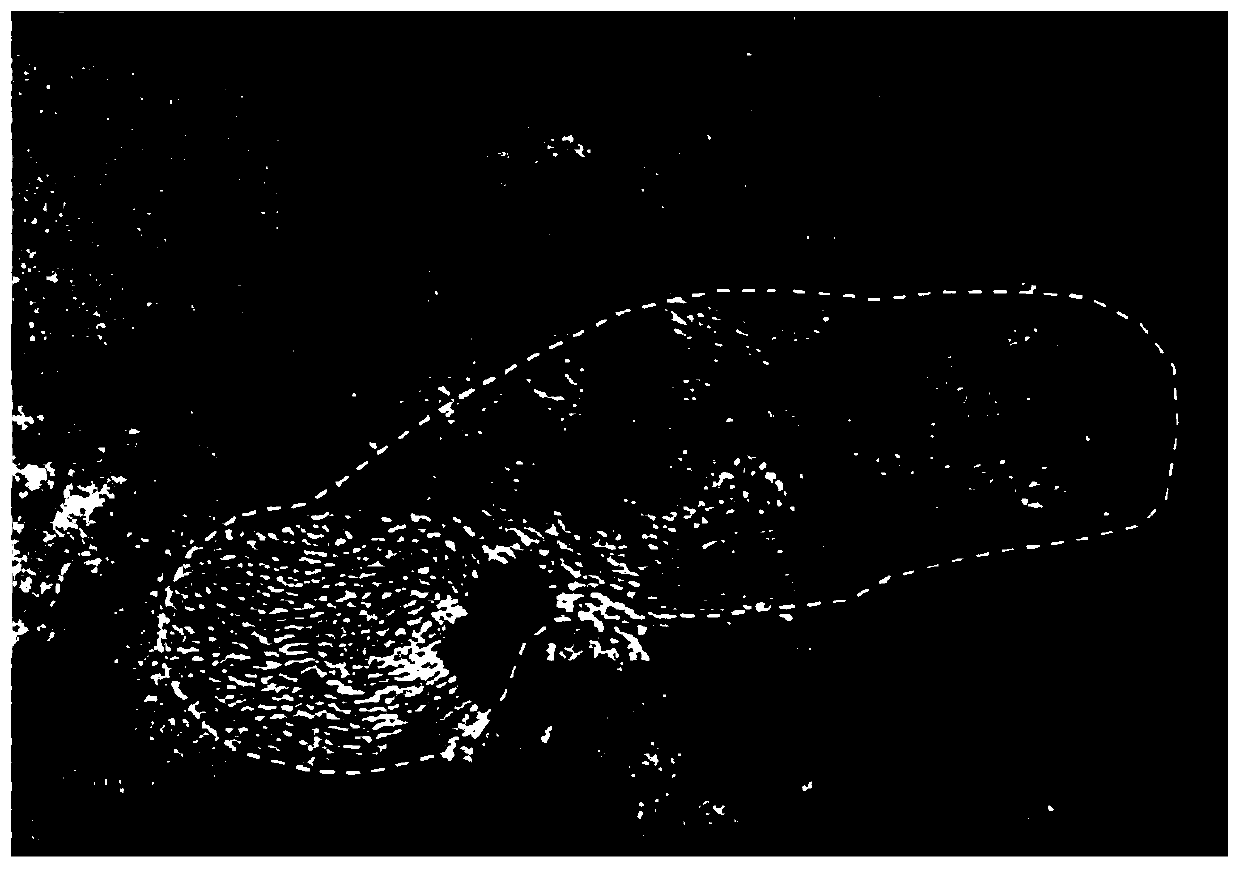

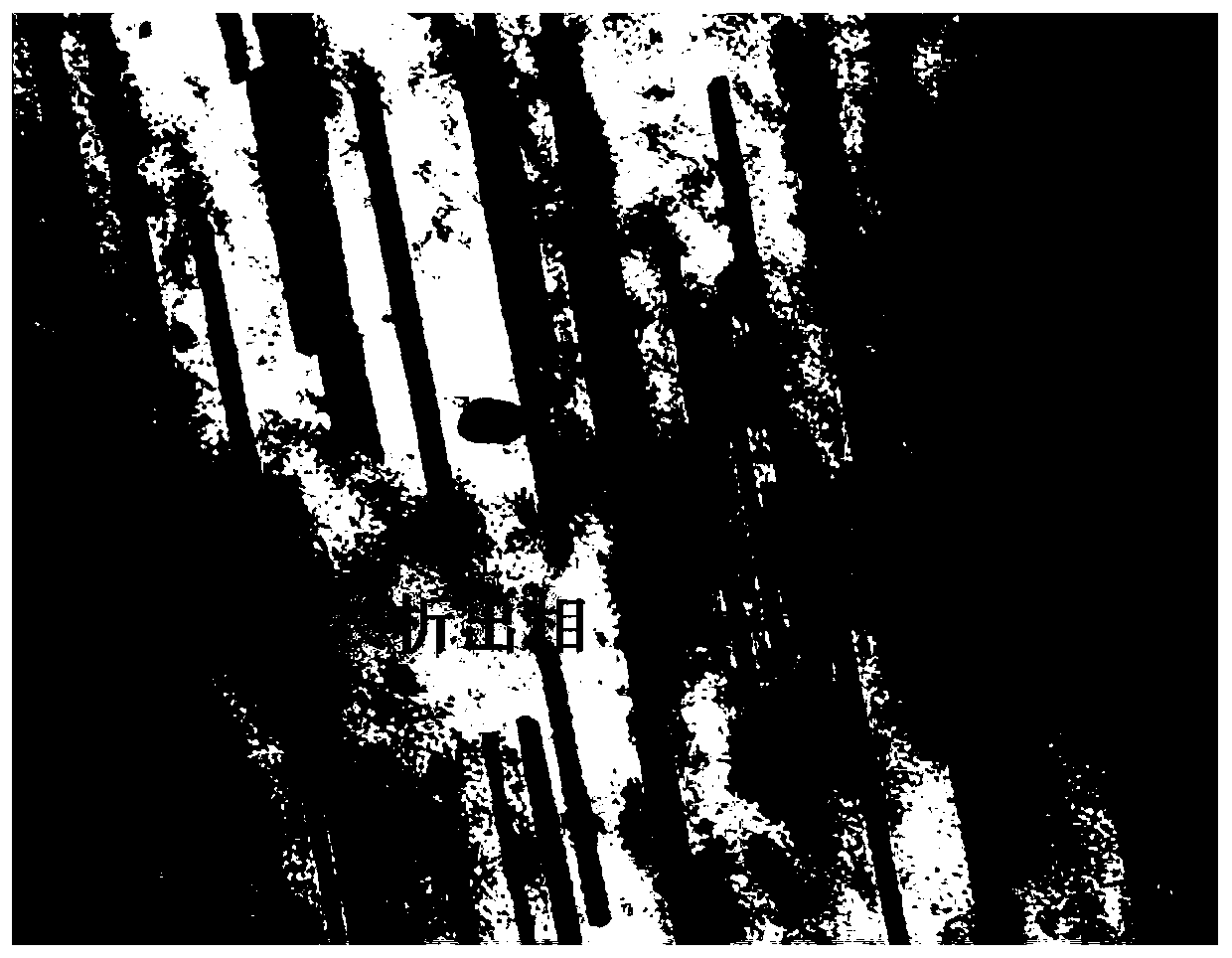

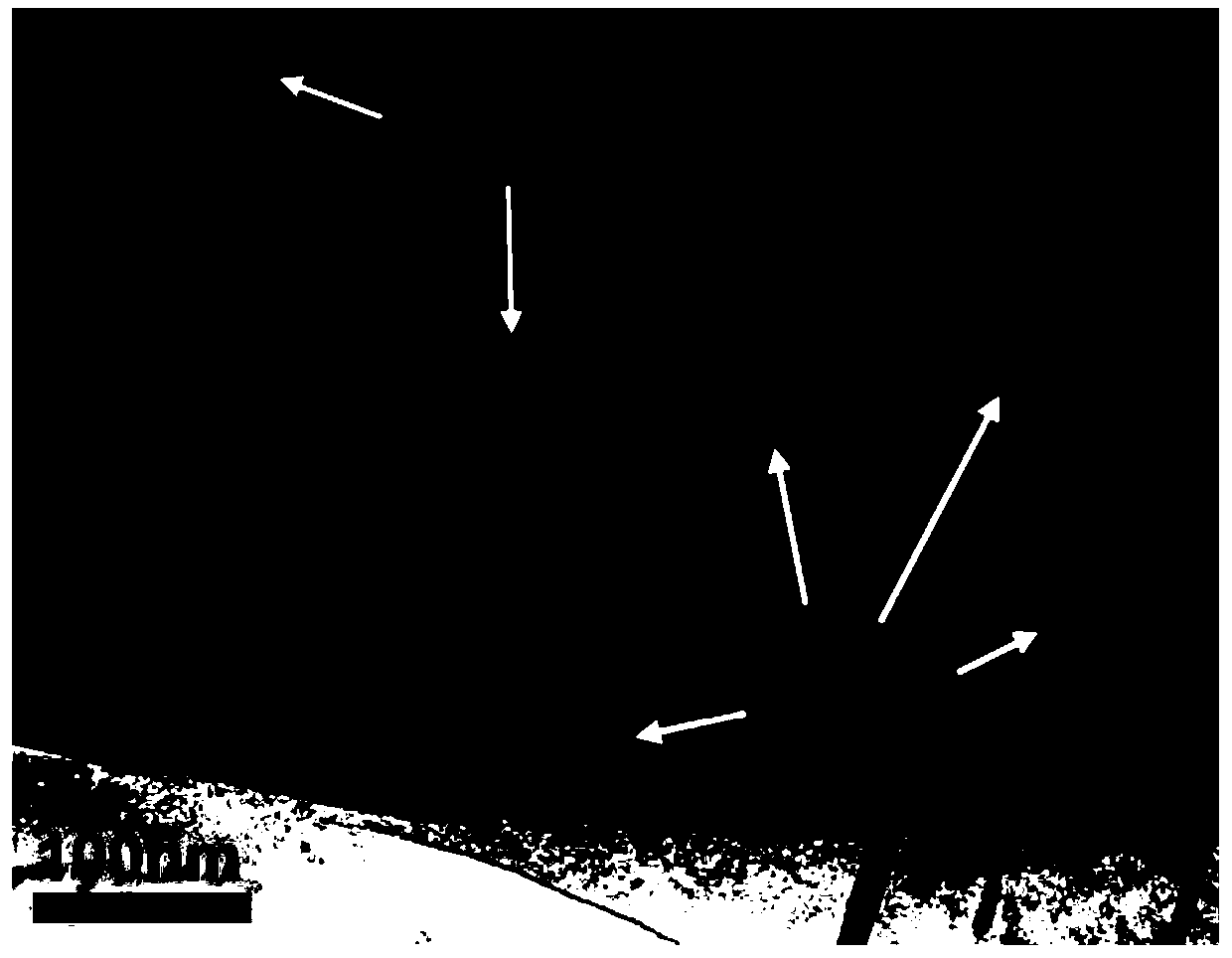

Image

Examples

Embodiment 1

[0019] Mix pure magnesium powder, zinc powder and carbon nanotubes evenly and press them into blocks. The specific components of the block are Mg: 95.95wt.%, Zn: 4wt.%, CNTs: 0.05wt.%. The prepared composite block The body is placed in a vacuum tube furnace with a vacuum of -10 5 Pa, react in situ at 360°C for 1 hour, and then cool with the furnace; through the back extrusion process, the in situ reacted block is back extruded into a rod, and then the rod is placed in a furnace with a protective atmosphere (argon) Inside, artificial aging at 160°C for 9h, and finally cooled to room temperature to obtain a carbon nanotube-reinforced magnesium-based composite material with a tensile strength of 290MPa and a thermal conductivity of 145W / (m·K).

Embodiment 2

[0021] Mix pure magnesium powder, zinc powder and carbon nanotubes evenly and press them into blocks. The specific components of the block are Mg: 93.8wt.%, Zn: 6wt.%, CNTs: 0.2wt.%. The prepared composite block The body is placed in a vacuum tube furnace with a vacuum of -10 5 Pa, react in situ at 400°C for 2 hours, and then cool with the furnace; through the back extrusion process, the block after the in situ reaction is back extruded into a rod, and then the rod is placed in a furnace with a protective atmosphere (argon) Inside, artificial aging at 175°C for 12h, and finally cooled to room temperature to obtain a carbon nanotube-reinforced magnesium-based composite material with a tensile strength of 320MPa and a thermal conductivity of 128W / (m·K).

Embodiment 3

[0023] Mix pure magnesium powder, zinc powder and carbon nanotubes evenly and press them into blocks. The specific components of the block are Mg: 93.6wt.%, Zn: 6wt.%, CNTs: 0.4wt.%. The prepared composite block The body is placed in a vacuum tube furnace with a vacuum of -10 5 Pa, react in situ at 400°C for 2 hours, and then cool with the furnace; through the back extrusion process, the block after the in situ reaction is back extruded into a rod, and then the rod is placed in a furnace with a protective atmosphere (argon) Inside, artificial aging at 175°C for 12h, and finally cooled to room temperature to obtain a carbon nanotube-reinforced magnesium-based composite material with a tensile strength of 342MPa and a thermal conductivity of 140W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com