Titanium alloy implant biological surface active coating and preparation method thereof

A biological surface and active coating technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., to improve the quality of the film layer, enhance biological activity, and enhance the effect of protein adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An embodiment of the titanium alloy implant biological surface active coating of the present invention, the titanium alloy implant biological surface active coating described in this embodiment is prepared by the following method:

[0035] The titanium alloy implant is placed in the electrolyte, the titanium alloy implant is used as the anode, and the electrolytic cell is used as the cathode. A bioactive micro-arc oxidation coating is formed on the surface;

[0036] The formula of the electrolyte is: sodium hydroxide 0.2mol / L, sodium dihydrogen phosphate 0.04mol / L, disodium oxalate tetraacetate 0.015mol / L, calcium acetate 0.1mol / L, nano-hydroxyapatite 1g / L , the solvent is deionized water.

[0037] The parameters of the micro-arc oxidation process are as follows: the micro-arc oxidation voltage is 300V, the frequency is 500Hz, the positive and negative duty cycles are +35% and -15%, respectively, and the processing time is 5min.

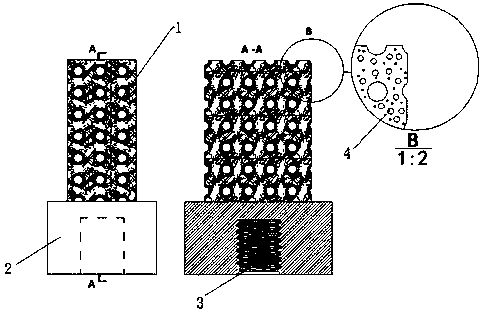

[0038] as attached figure 1 As shown...

Embodiment 2

[0044] A kind of embodiment of biological surface active coating of titanium alloy implant of the present invention, the preparation method of biological surface active coating of titanium alloy implant described in this embodiment is the same as embodiment 1, wherein,

[0045] The formula of the electrolyte is: sodium hydroxide 0.1mol / L, sodium dihydrogen phosphate 0.03mol / L, disodium oxalate tetraacetate 0.01mol / L, calcium acetate 0.01mol / L, nano-hydroxyapatite 0.5g / L L, the solvent is deionized water.

[0046] The parameters of the micro-arc oxidation process are as follows: the micro-arc oxidation voltage is 250V, the frequency is 700Hz, the positive and negative duty cycles are +55% and -35%, respectively, and the processing time is 10min.

Embodiment 3

[0048] A kind of embodiment of biological surface active coating of titanium alloy implant of the present invention, the preparation method of biological surface active coating of titanium alloy implant described in this embodiment is the same as embodiment 1, wherein,

[0049] The formula of the electrolyte is: sodium hydroxide 0.3mol / L, sodium dihydrogen phosphate 0.08mol / L, disodium oxalate tetraacetate 0.05mol / L, calcium acetate 0.5mol / L, nano-hydroxyapatite 3g / L , the solvent is deionized water.

[0050] The parameters of the micro-arc oxidation process are as follows: the micro-arc oxidation voltage is 350V, the frequency is 500Hz, the positive and negative duty ratios are +75% and -55%, respectively, and the processing time is 15min.

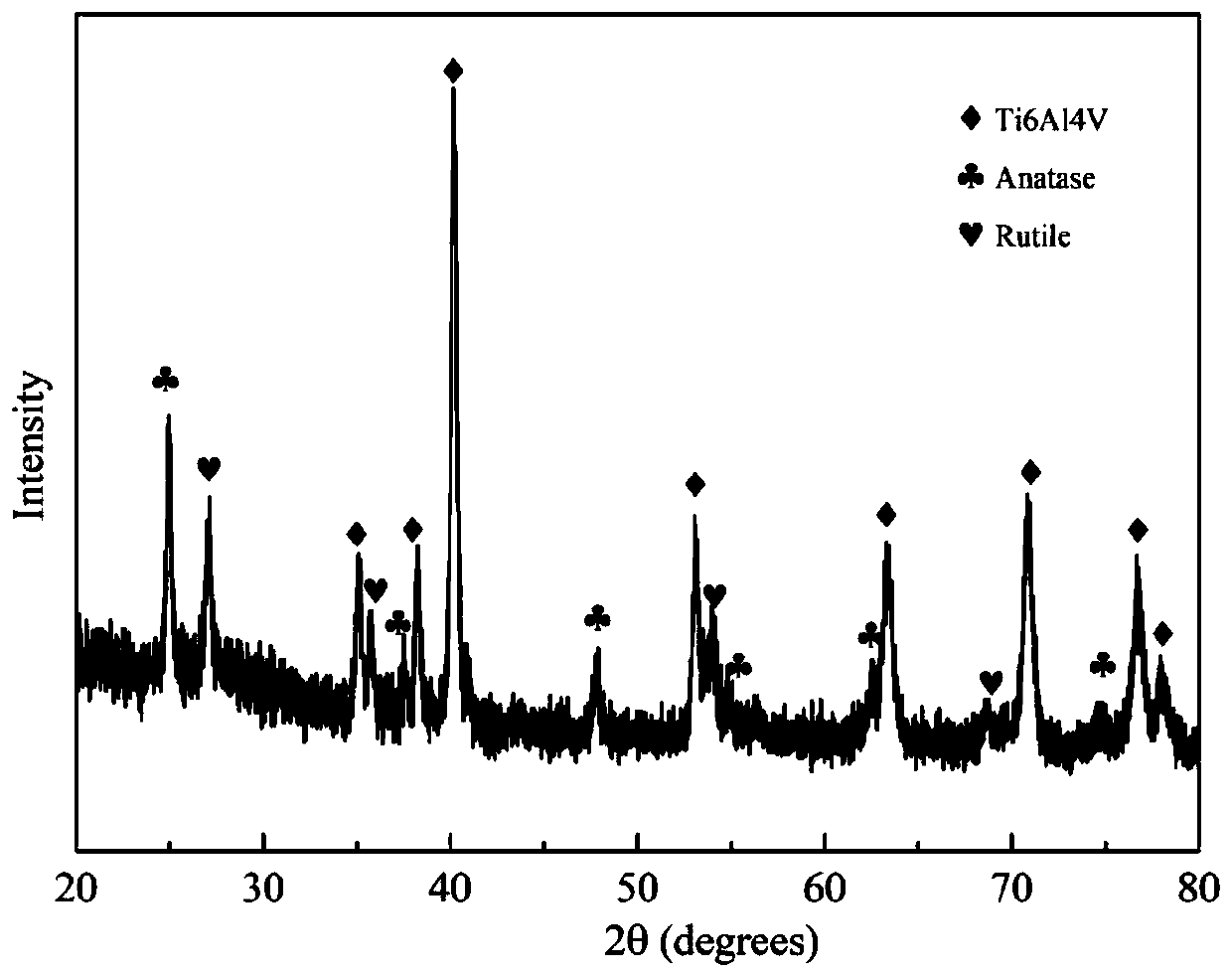

[0051] The present invention has carried out X-ray energy spectrum (XRD) analysis to the porous implant after above-mentioned case processing, specifically as attached figure 2 As shown, it was found that there were different crystal fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com