Preparation method of high-energy graphene battery negative electrode material

A battery anode, graphene technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of poor cycle performance, low first coulomb efficiency, etc., and achieve good cycle performance, high first coulomb efficiency, fast intercalation and The effect of de-embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

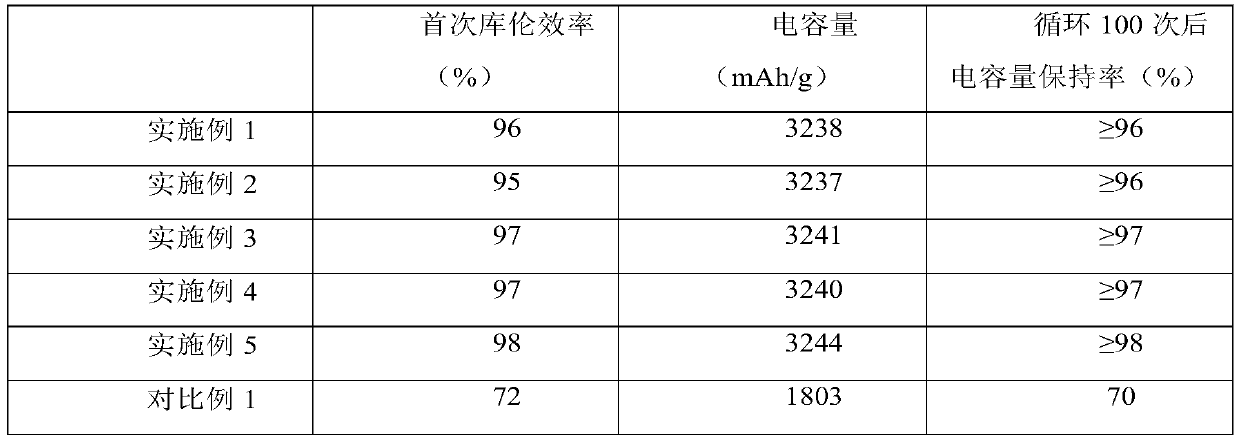

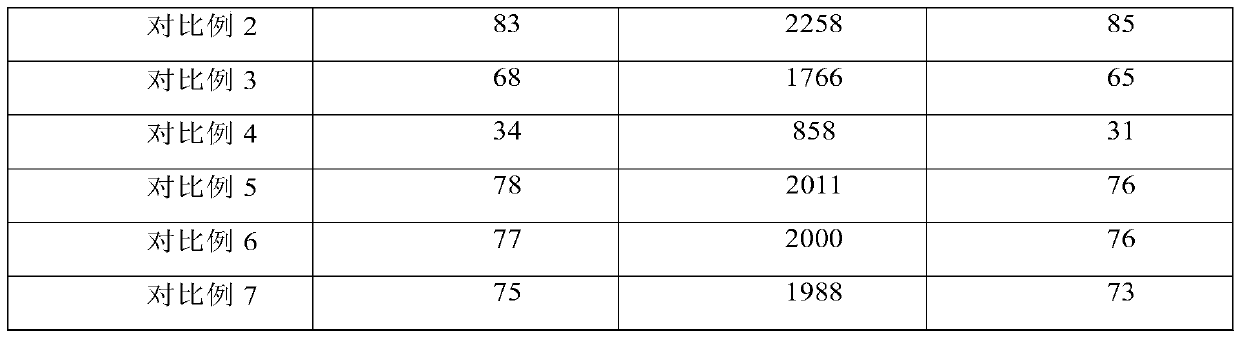

Embodiment 1

[0026] A preparation method of a high-energy graphene battery negative electrode material is to add Si-B-Co co-doped graphene oxide and carbon fiber-quartz fiber composite fiber into the aqueous solution of p-toluenesulfonic acid according to the mass ratio of 1:0.1, heat, and quickly add Ethyl orthosilicate, slowly drip toluene while stirring (utilize 10 minutes to drop at a constant speed), obtain gel body, aging, reduction, freeze-drying, promptly obtains described a kind of high-energy graphene battery negative electrode material; The Si-B-Co co-doped graphene oxide is to add nano-silicon powder, boric acid, and cobalt nitrate hexahydrate into the graphene oxide dispersion, and heat at 500°C for 10 hours under an inert atmosphere (argon) and ultrasonic vibration conditions. Post-treatment, wherein, the molar ratio of nano silicon powder, boric acid, cobalt nitrate hexahydrate and graphene oxide dispersion liquid contained in graphene oxide is 0.03:0.06:0.02:1; the carbon fi...

Embodiment 2

[0035] A preparation method of a high-energy graphene battery negative electrode material is to add Si-B-Co co-doped graphene oxide and carbon fiber-quartz fiber composite fiber into p-toluenesulfonic acid aqueous solution according to the mass ratio of 1:0.2, heat, and quickly add Ethyl orthosilicate, slowly drip toluene while stirring (utilize 12 minutes to drop at a constant speed), obtain gel, aging, reduction, freeze-drying, promptly obtains described a kind of high-energy graphene battery negative electrode material; The Si-B-Co co-doped graphene oxide is to add nano-silicon powder, boric acid, and cobalt nitrate hexahydrate into the graphene oxide dispersion, and heat at 600°C for 12 hours under an inert atmosphere (helium) and ultrasonic vibration conditions. Post-treatment, wherein, the molar ratio of nano silicon powder, boric acid, cobalt nitrate hexahydrate and graphene oxide dispersion liquid contained in graphene oxide is 0.04:0.07:0.03:1; the carbon fiber-quartz ...

Embodiment 3

[0044] A preparation method of a high-energy graphene battery negative electrode material is to add Si-B-Co co-doped graphene oxide and carbon fiber-quartz fiber composite fiber into the aqueous solution of p-toluenesulfonic acid according to the mass ratio of 1:0.1, heat, and quickly add Ethyl orthosilicate, slowly drip toluene while stirring (utilize 12 minutes to drop at a constant speed), obtain gel, aging, reduction, freeze-drying, promptly obtains described a kind of high-energy graphene battery negative electrode material; The Si-B-Co co-doped graphene oxide is to add nano-silicon powder, boric acid, and cobalt nitrate hexahydrate into the graphene oxide dispersion, and heat at 500°C for 12 hours under an inert atmosphere (argon) and ultrasonic vibration conditions. Post-treatment, wherein, the molar ratio of nano silicon powder, boric acid, cobalt nitrate hexahydrate and graphene oxide dispersion liquid contained in graphene oxide is 0.03:0.07:0.02:1; the carbon fiber-q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com