Preparation method for optimizing performance of porous dendritic Pt-Ru-Ni alloy nanoparticles

A technology of alloy nanoparticles and alloy nanoparticles, which is applied in the field of preparing porous dendritic Pt-Ru-Ni alloy nanoparticles by solvothermal synthesis, can solve the problems of easy poisoning and expensive Pt catalyst, and achieve high specific surface area, excellent Effects of durability and CO poisoning resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

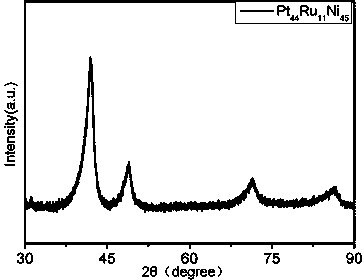

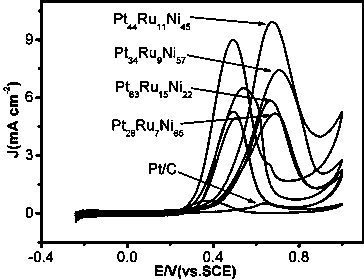

[0023] 8 mg Pt(acac) 2 , 6 mg Ni(acac) 2 , 2 mg Ru(acac) 3 , 9 ml of oleylamine and 1 ml of oleic acid were added to the beaker, then the mixed solution was sonicated for 10 min, and stirred for 30 min until the solution was clear; then 0.8 ml of formaldehyde was added while stirring, and the stirring was continued for 15 min. The mixture was transferred to a 20 ml reaction kettle, placed in an oven, and kept at 170 °C for 12 h. After the reaction, through ethanol centrifugal washing, freeze-drying and other processing steps, porous dendritic Pt 44 Ru 11 Ni 45 alloy nanoparticles. (Such as figure 2 shown).

Embodiment 2

[0026] 8 mg Pt(acac) 2 , 2 mg Ni(acac) 2 , 2 mg Ru(acac) 3 , 9 ml of oleylamine and 1 ml of oleic acid were added to the beaker, then the mixed solution was sonicated for 10 min, and stirred for 30 min until the solution was clear; then 0.8 ml of formaldehyde was added while stirring, and the stirring was continued for 15 min. The mixture was transferred to a 20 ml reaction kettle, placed in an oven, and kept at 170 °C for 12 h. After the reaction, through ethanol centrifugal washing, freeze-drying and other processing steps, porous dendritic Pt 63 Ru 15 Ni 22 alloy nanoparticles. (Such as Figure 5 shown).

[0027] Methanol (formic acid) electro-oxidation test: The anode electro-oxidation performance test is carried out on a CHI650D electrochemical workstation using a conventional three-electrode system. A saturated calomel electrode (SCE) was used as the reference electrode, a platinum wire was used as the counter electrode, and a glassy carbon electrode (GC) with a ...

Embodiment 3

[0029] 8 mg Pt(acac) 2 , 10 mg Ni(acac) 2 , 2 mg Ru(acac) 3 , 9 ml of oleylamine and 1 ml of oleic acid were added to the beaker, then the mixed solution was sonicated for 10 min, and stirred for 30 min until the solution was clear; then 0.8 ml of formaldehyde was added while stirring, and the stirring was continued for 15 min. The mixture was transferred to a 20 ml reaction kettle, placed in an oven, and kept at 170 °C for 12 h. After the reaction, through ethanol centrifugal washing, freeze-drying and other processing steps, porous dendritic Pt 34 Ru 9 Ni 57 alloy nanoparticles. (Such as Figure 6 shown).

[0030] Methanol (formic acid) electro-oxidation test: The anode electro-oxidation performance test is carried out on a CHI650D electrochemical workstation using a conventional three-electrode system. A saturated calomel electrode (SCE) was used as the reference electrode, a platinum wire was used as the counter electrode, and a glassy carbon electrode (GC) with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com