Preparation method of alkaline redox flow battery system with high energy density and low cost

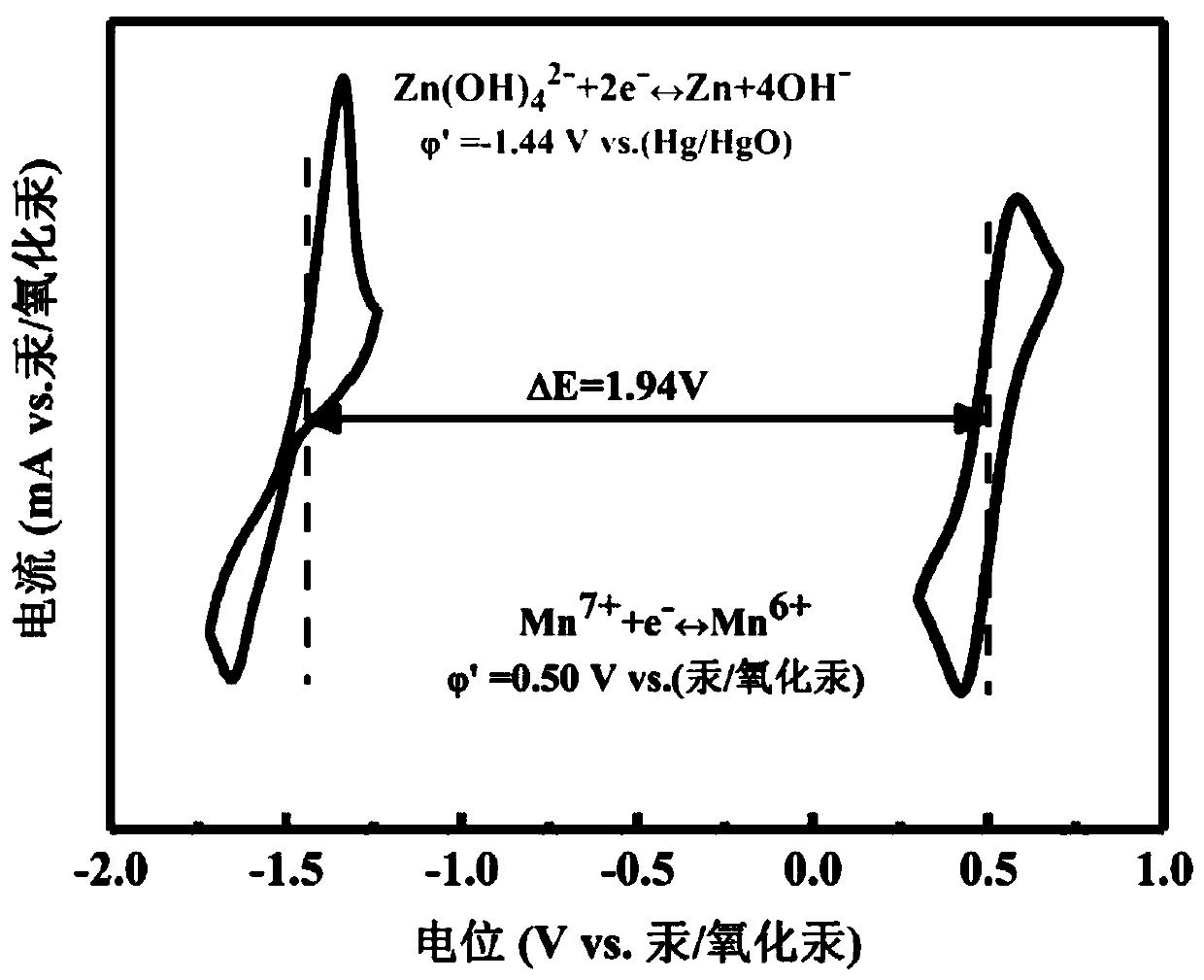

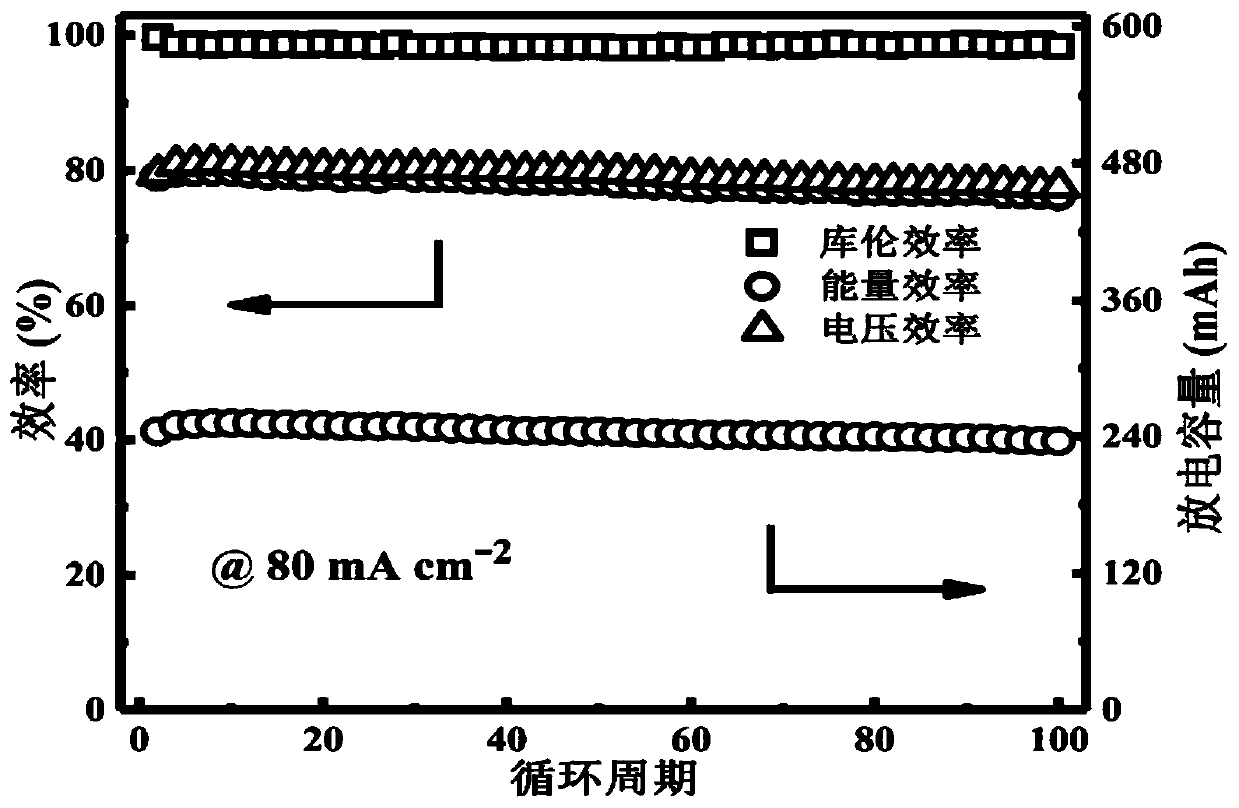

A high-energy-density, low-cost technology, applied in fuel cells, battery electrodes, regenerative fuel cells, etc., can solve the problems of low energy density and high cost of flow batteries, and achieve excellent reversibility, suitable potential, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this example, the preparation method of the alkaline flow battery system is as follows:

[0042] 1. The ionization treatment process of Nafion membrane (the present embodiment adopts Nafion212), comprises the following steps:

[0043] (1) A Nafion membrane with a length of 7.5 cm and a width of 5.5 cm was placed in a molar concentration of 1M H 2 o 2 In aqueous solution, wash at 80°C for 1 hour at a constant temperature;

[0044] (2) Place the treated Nafion membrane in deionized water, and treat it at a constant temperature of 60° C. for 40 minutes to obtain a clean Nafion membrane;

[0045](3) Place the above-mentioned clean Nafion membrane in an aqueous solution of hydrochloric acid with a molar concentration of 1M and protonate it at a constant temperature of 80°C for 1h;

[0046] (4) Place the protonated Nafion membrane in deionized water, and treat it at a constant temperature of 60°C for 40 minutes to obtain a clean Nafion membrane;

[0047] (5) Place the ...

Embodiment 2

[0058] The difference from Example 1 is that the preparation of the electrolyte:

[0059] (1) Dissolve sodium permanganate in an aqueous sodium hydroxide solution with a molar concentration of 1.5M. After completely dissolving, obtain an alkaline aqueous solution of sodium permanganate with a molar concentration of 1M, seal it in a positive electrode liquid storage tank, and use it as a battery positive electrolyte.

[0060] (2) Sodium hydroxide is dissolved in deionized water. After being completely dissolved, an aqueous sodium hydroxide solution with a molar concentration of 1.5M is obtained. After being completely dissolved, it is sealed in a negative electrode liquid storage tank and used as the negative electrode electrolyte of the battery.

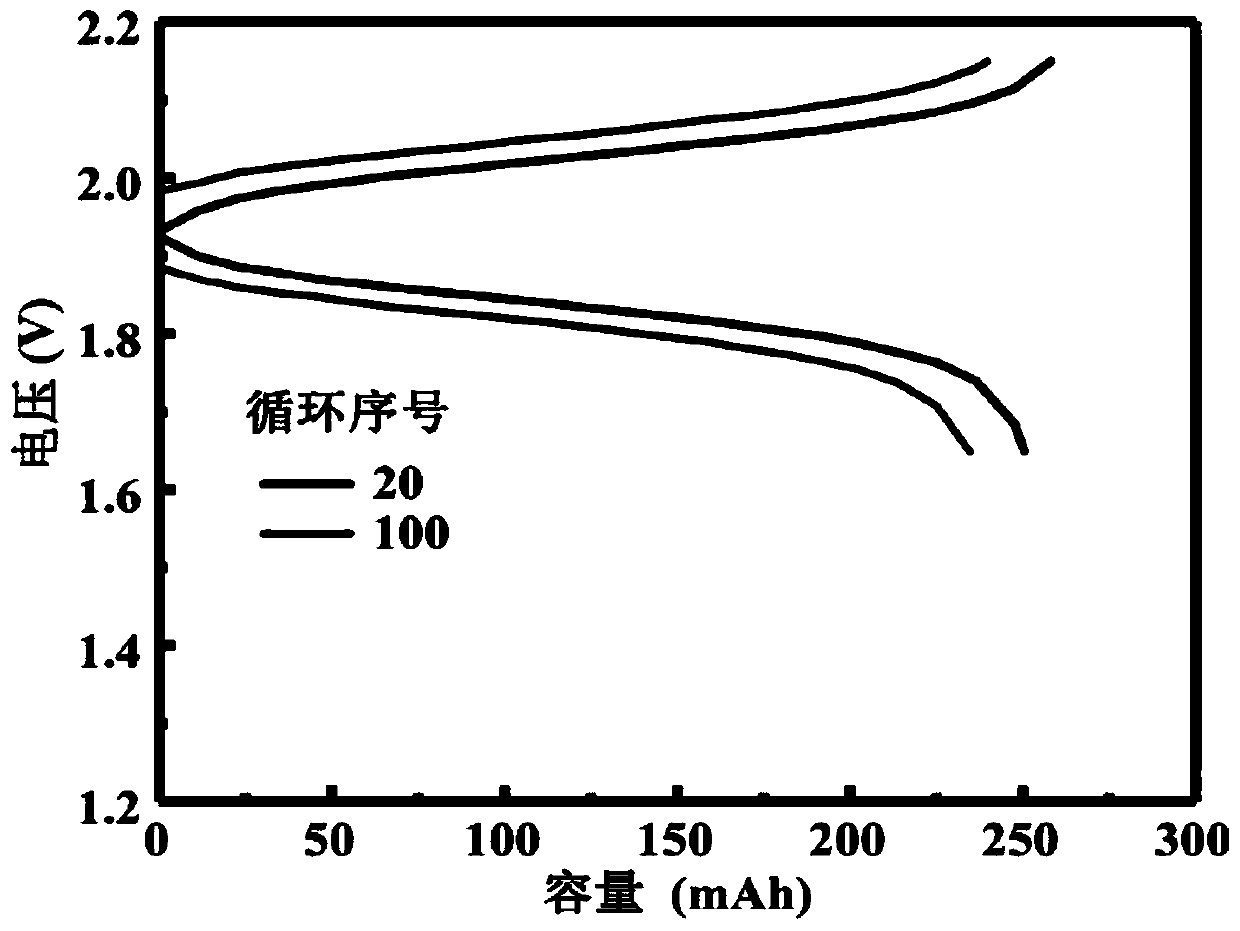

[0061] In this embodiment, carbon felt is used as the positive electrode material of the flow battery, zinc sheet is used as the negative electrode material of the flow battery, and a flow battery of the sodium permanganate-zinc plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com