Composite milling material increasing and decreasing type in-situ repairing device and method for deepwater pipeline

An in-situ repair technology for deep-water pipelines, applied in the direction of additive processing, welding equipment, laser welding equipment, etc., can solve the problems of reducing mechanical properties, affecting printing quality, hole cracks, etc., to improve repair quality, good mechanical properties, The effect of less cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

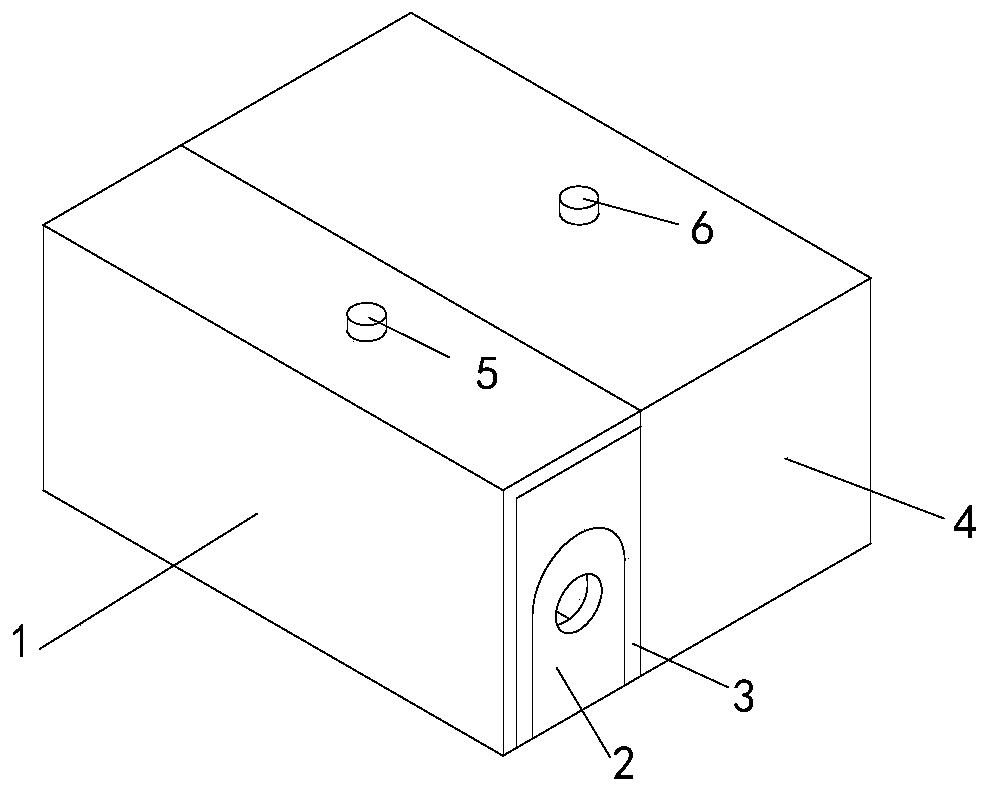

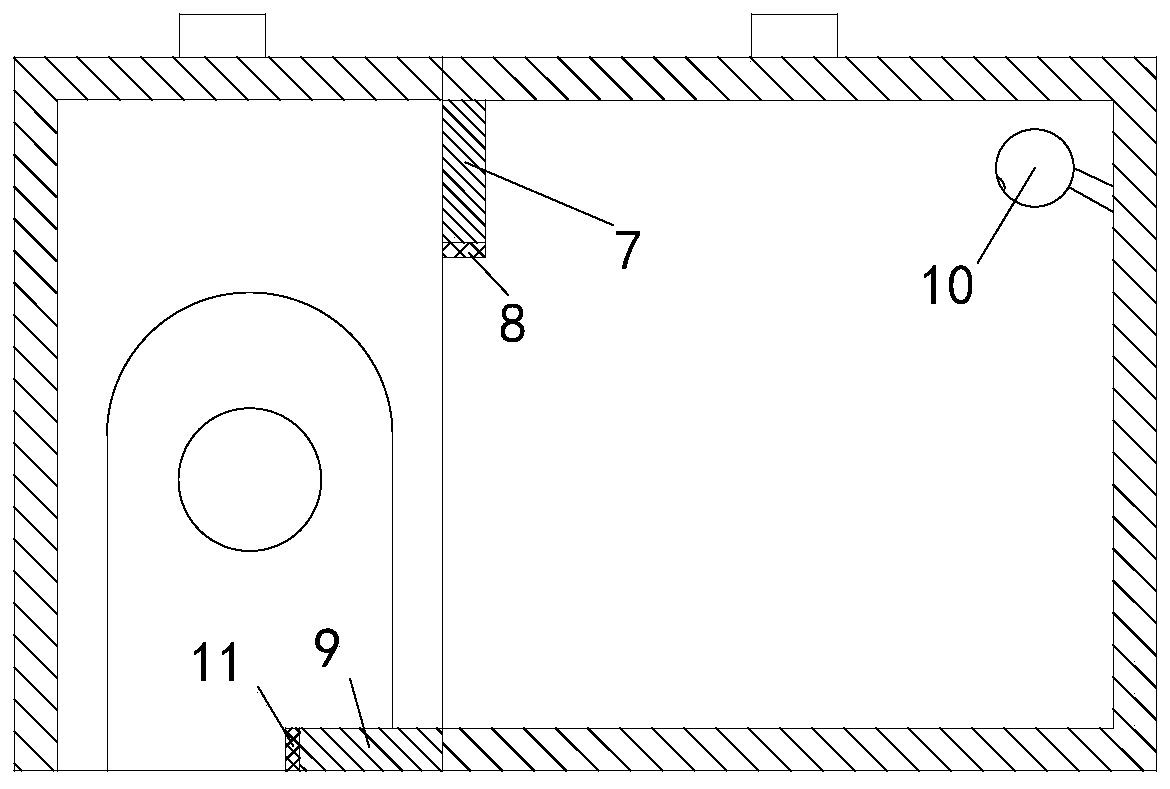

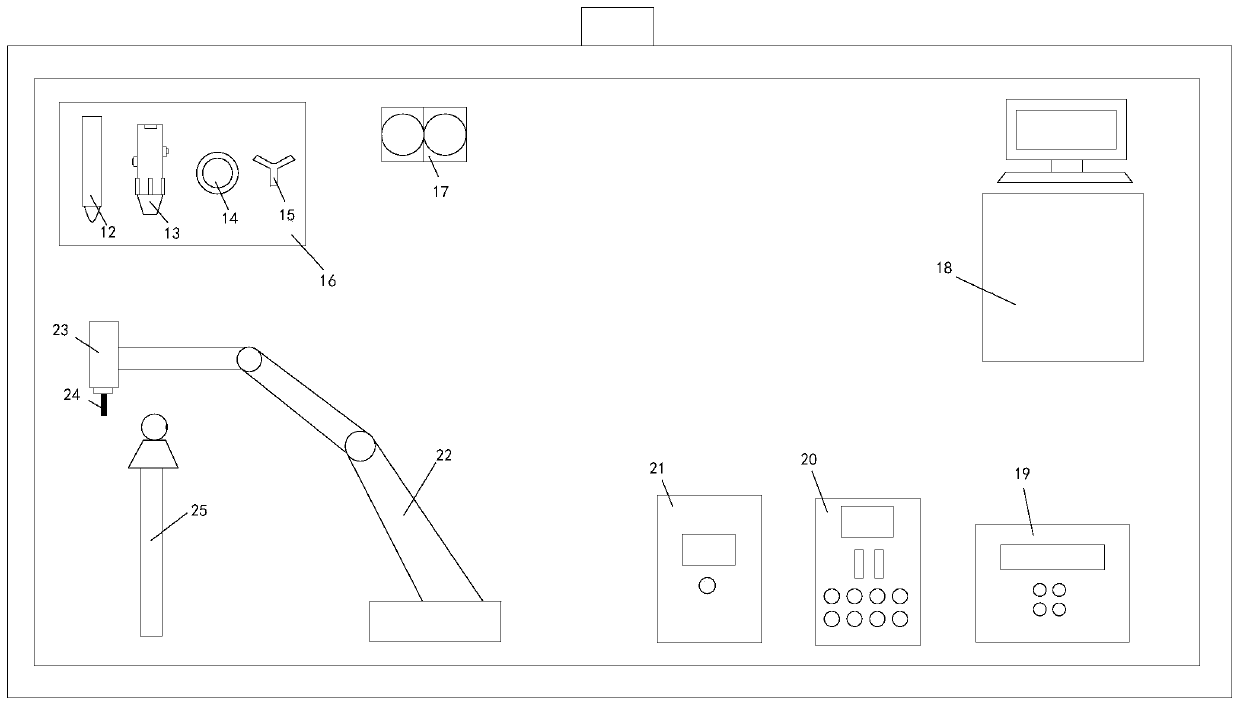

[0045] An in-situ repair equipment for deep-water pipeline compound milling with addition and subtraction of materials, including a repair cabin 1, an equipment cabin 4, a tool magazine 16, a local control system 18, a six-axis robot 22, an additive repair system, a subtractive processing system, and a monitoring system;

[0046] Such as figure 1 and figure 2 Shown are the structural schematic diagram and the cross-sectional schematic diagram of the cabin in the repairing equipment, respectively.

[0047] Both sides of the repair cabin are provided with a replaceable hatch 3 and a sealed hatch 2, which are used to load the pipeline to be repaired into the repair cabin and ensure the airtightness of the cabin; the top of the repair cabin is provided with a protective gas pipe interface 5 for Through the gas cylinder equipped with the water surface, high-pressure protective gas is provided to the cabin to remove the liquid in the cabin; the bottom of the repair cabin is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com