Antibacterial non-woven fabric, preparation method of antibacterial non-woven fabric and mask with antibacterial non-woven fabric

A technology of non-woven fabrics and masks, which is used in textiles and papermaking, non-woven fabrics, rayon manufacturing, etc., can solve the problem that masks are easy to accumulate viruses and bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An antibacterial non-woven fabric, the raw material of the antibacterial non-woven fabric comprises the following components by weight: 75-100 parts of polypropylene, 10-25 parts of sodium styrene sulfonate, 10-20 parts of silane coupling agent, polyhexa 0.15-1 part of methylene biguanide hydrochloride, 0.05-0.4 part of zinc salt, 1-5 parts of bamboo charcoal fiber, and 0.01-0.1 part of nano-scale fumed silicon dioxide.

[0032] Specifically, polyhexamethylene biguanide (PHMB) has a broad spectrum of sterilization, low effective concentration, fast action speed, stable properties, high-quality properties of being easily soluble in water, can be used at room temperature, long-term antibacterial, no side effects, no Corrosive, colorless, odorless, non-toxic, non-flammable, non-explosive, safe to use, it is the best fungicide in practice. Bactericidal effect of polyhexamethylene biguanide: 0.02% polyhexamethylene biguanide has a 100% sterilization rate against Escherichia ...

Embodiment 2

[0036] The invention also discloses a preparation method of antibacterial non-woven fabric, comprising the following steps:

[0037](1) Weighing: Weigh the following components by weight: 75-100 parts of polypropylene, 10-25 parts of sodium styrene sulfonate, 10-20 parts of silane coupling agent, 0.15 parts of polyhexamethylene biguanide hydrochloride ~1 part, 0.05~0.4 parts of zinc salt, 1~5 parts of bamboo charcoal fiber, 0.01~0.1 part of nano-scale fumed silica;

[0038] (2) Heat the weighed polypropylene, sodium styrene sulfonate, and silane coupling agent aqueous solution in a water bath to 60±2°C, keep warm and stir for 2.5±0.5h, then irradiate with ultraviolet rays for 15±2min and then cool down to 25±2°C to obtain a polypropylene mixture;

[0039] (3) The polyhexamethylene biguanide hydrochloride, zinc salt that weighs is adopted the aqueous solution reaction method to make complex solution, then adds nanoscale fumed silicon dioxide to obtain composite antimicrobial a...

Embodiment 3

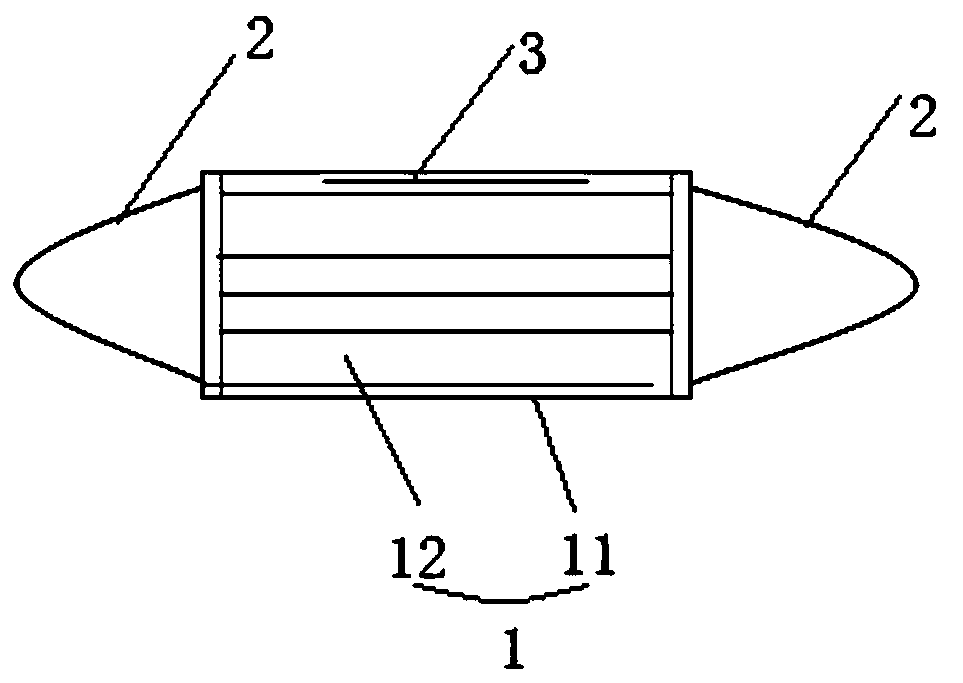

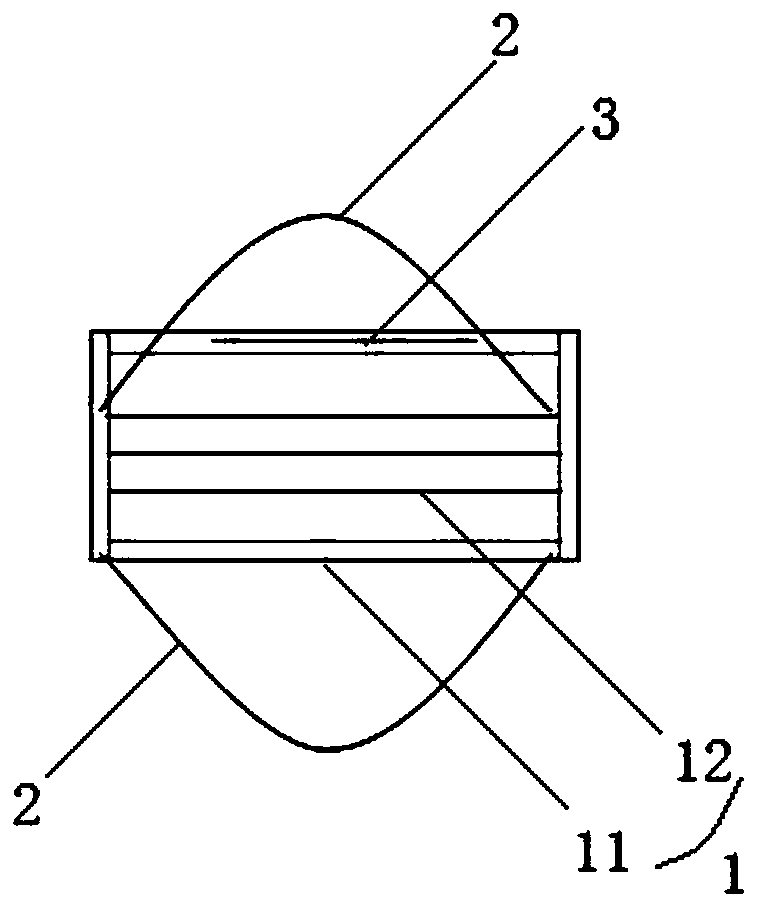

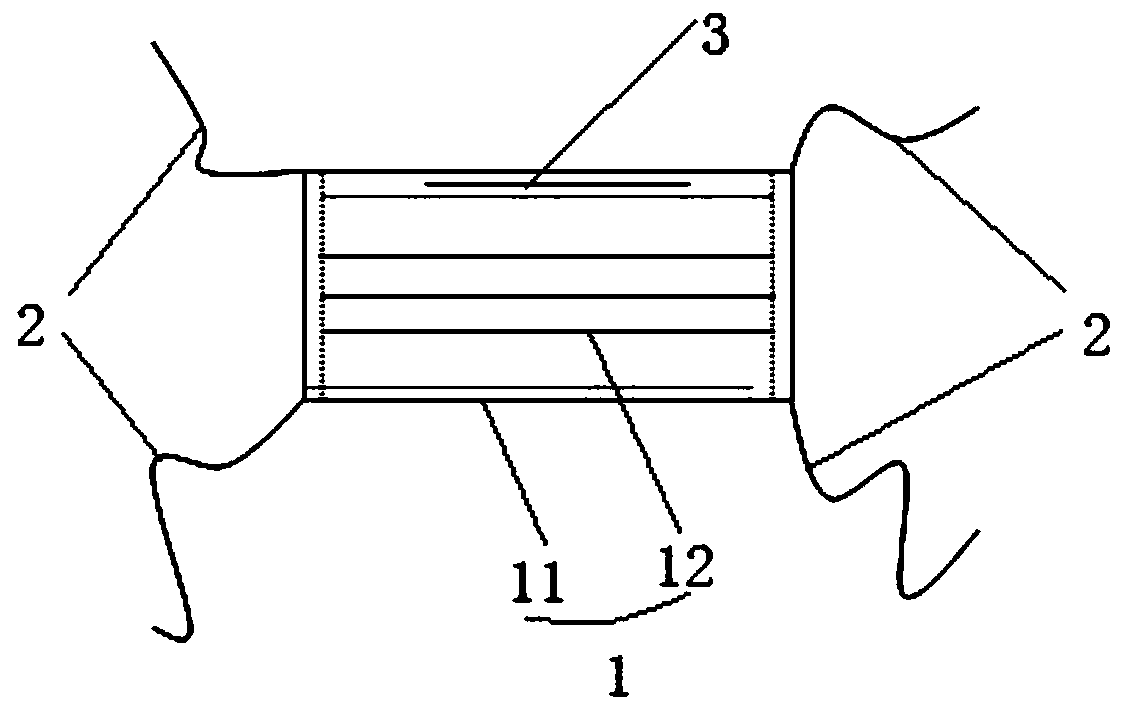

[0051] like Figure 1~4 As shown, the present invention also discloses a mouth mask with antibacterial non-woven fabric, comprising a mouth mask body 1, a mask belt 2, and a nose strip 3, and the mouth mask body 1 includes at least one antibacterial non-woven fabric layer 11, at least one The filter cloth layer 12 of layer, described antibacterial non-woven fabric layer 11 is bonded with filter cloth layer 12, and described filter cloth layer 12 is arranged far away from face, and antibacterial nonwoven fabric layer 11 is arranged near face; Described mouth mask belt 2 is arranged It is on the side of the mask body 1, and is used to closely fit the mask body 1 to the face; the nose strip 3 is arranged on the top of the mask body 1, and is used to closely fit the mask body 1 to the bridge of the nose; the antibacterial nonwoven The material of cloth layer 11 is the antibacterial non-woven fabric described in claim 1.

[0052] Preferably, the mask straps 2 are arranged on both ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com