Method for evaluating segmented water production rate of multi-stage tight oil fracturing well by using tracer

An evaluation method and tracer technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the undiscovered segmental formation water production, segmental water cut monitoring, evaluation error, and unreasonable explanation etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to have a clearer understanding of the technical features, effects, and implementation modes of the present invention, the technical solution of the present invention will now be described in detail below.

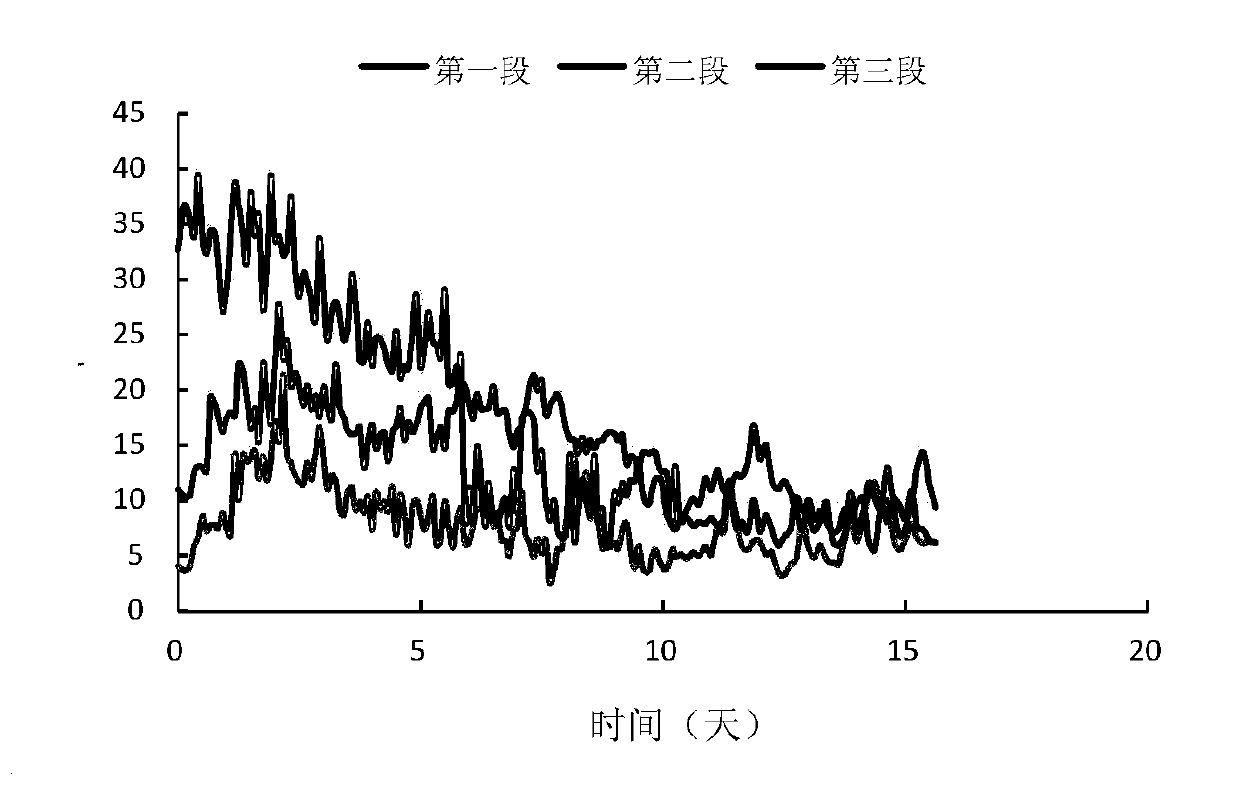

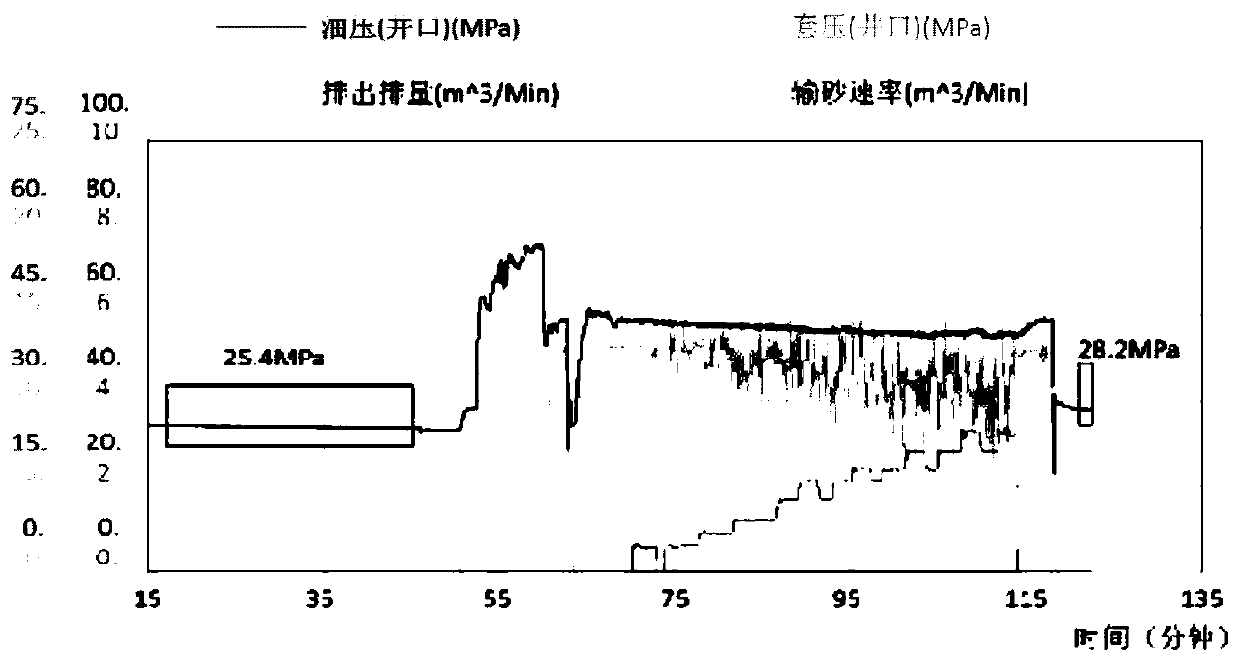

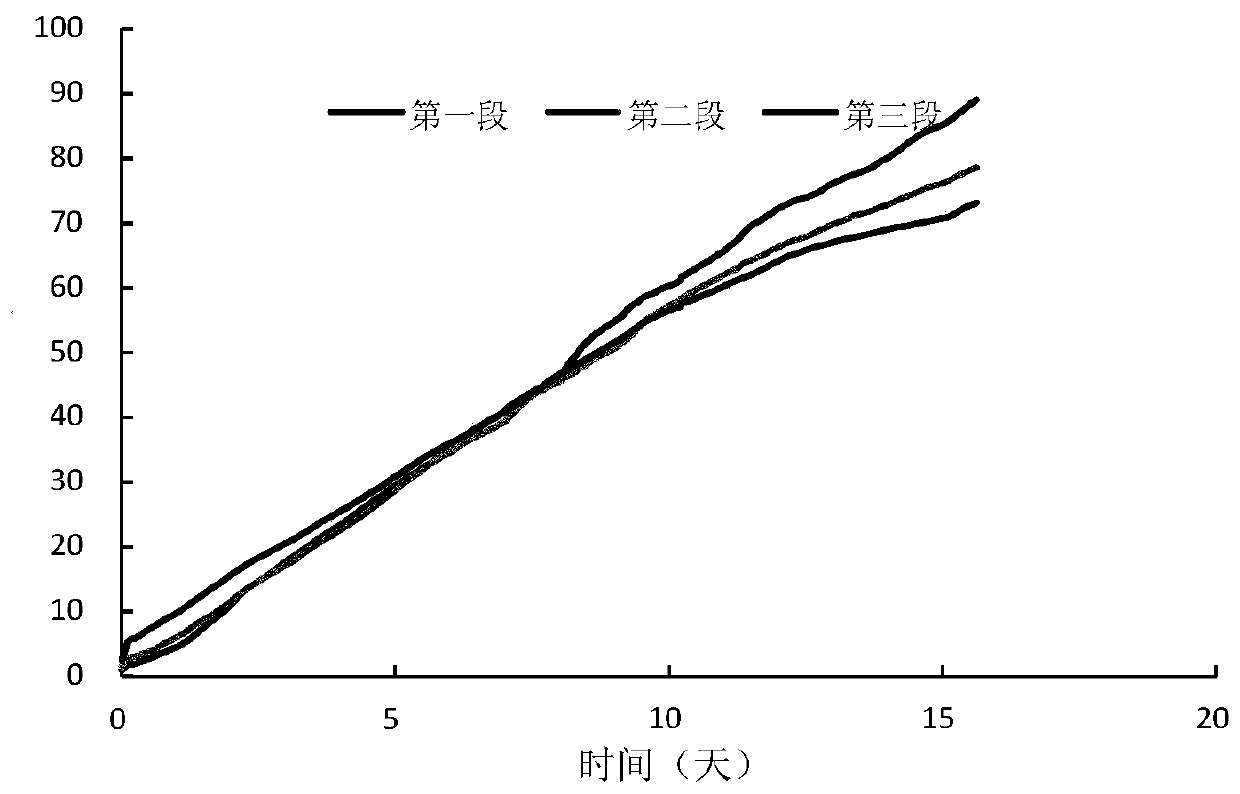

[0077] This embodiment provides a tracer evaluation method for staged water production and contribution rate in multistage fracturing wells in tight oil. The object of this method is the 3-stage fracturing of a tight oil horizontal well in Daqing Oilfield. The tracer monitoring and evaluation method of this implementation example is used to comprehensively evaluate the flowback rate, liquid production contribution rate, and formation water production of each fracturing stage. .

[0078] The tracer is a rare element or a metal element complex; the rare element includes lithium, rubidium, cesium, titanium, zirconium, gallium, indium, scandium, yttrium, lanthanum, cerium, praseodymium, neodymium, samarium, europium , gadolinium, terbium, dysprosium, holmium, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com