A kind of preparation method of high polymer composite nano particle compatibilizer

A composite nanoparticle and nanoparticle technology, applied in the field of compatibilizers, can solve the problems of complex preparation process, inconvenient handling, unfriendly environment, etc., and achieve the effects of simple preparation process, convenient handling and many surface atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

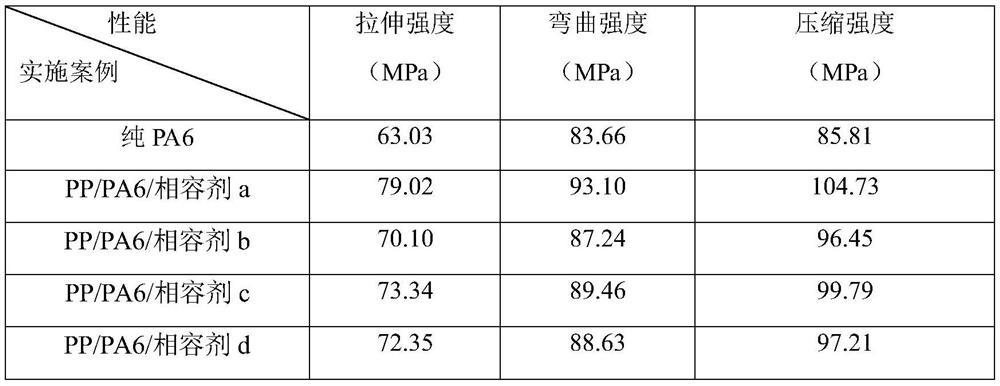

Examples

Embodiment 1

[0029] (1) Graphene oxide was ultrasonically treated for 15 minutes to obtain a graphene oxide aqueous solution with a concentration of 1.00 g / L. Then, 50 mL of graphene oxide aqueous solution was added drop by drop into the flask containing 100 mL of branched polyethyleneimine solution within 10 to 15 minutes, and stirred and reacted at 80° C. for 8 h. Then the modified graphene oxide aqueous solution was centrifuged and washed with deionized water to remove residual polyethyleneimine, and finally, intermediate 1 was obtained by freeze-drying at -50 °C. Wherein, the concentration of polyethyleneimine solution is 1.00g / L.

[0030] (2) The 0.11g intermediate 1 obtained in (1) was dispersed in 50ml xylene (analytical grade: Tianjin Fuchen Chemical Reagent Factory) and ultrasonically treated for 30 minutes to obtain a suspension, expressed as M; meanwhile, in Dissolve 0.05g of polypropylene grafted maleic anhydride (PP-g-MAH: standard material, Suzhou Huitongwang Plastic Chemica...

Embodiment 2

[0034] (1) Graphene oxide was ultrasonically treated for 15 minutes to obtain a graphene oxide aqueous solution with a concentration of 1.00 g / L. Then, 50 mL of graphene oxide aqueous solution was added drop by drop into a 50 mL flask containing branched polyethyleneimine, and stirred at 80° C. for 8 h. Then the modified graphene oxide aqueous solution was centrifuged and washed with deionized water to remove residual polyethyleneimine, and finally, intermediate 1 was obtained after freeze-drying. Wherein, the concentration of polyethyleneimine solution is 1.00g / L.

[0035] (2) Disperse 0.72 g of intermediate 1 obtained in (1) in 50 ml of xylene and ultrasonically treat it for 30 minutes to obtain a suspension, denoted as M; at the same time, 0.05 g of polypropylene was grafted with maleic acid at 90 ° C. The acid anhydride was dissolved in 50ml of xylene, and the solution was denoted as N; then, the solution M and the solution N were reacted under mechanical stirring at 110°...

Embodiment 3

[0037] (1) Graphene oxide was ultrasonically treated for 15 minutes to obtain a graphene oxide aqueous solution with a concentration of 1.00 g / L. Then, 50 mL of graphene oxide aqueous solution was added drop by drop into a 50 mL flask containing branched polyethyleneimine, and stirred at 80° C. for 8 h. Then the modified graphene oxide aqueous solution was centrifuged and washed with deionized water to remove residual polyethyleneimine, and finally, intermediate 1 was obtained after freeze-drying. Wherein, the concentration of polyethyleneimine solution is 1.00g / L.

[0038] (2) Disperse 0.72 g of intermediate 1 obtained in (1) in 50 ml of xylene and ultrasonically treat it for 30 minutes to obtain a suspension, denoted as M; at the same time, 0.1 g of polypropylene was grafted with maleic acid at 90 ° C. The acid anhydride was dissolved in 50ml of xylene, and the solution was denoted as N; then, the solution M and the solution N were reacted under mechanical stirring at 110°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com