Ultra-thin composite slice stone-like coating and preparation method and application thereof

A technology of composite rock flakes and real stone paint, applied in coating, building, building structure and other directions, can solve the problems of weather resistance, poor durability, poor adhesion of paint film, affecting decorative effect, etc., to improve decorative effect and good adhesion , the effect of low self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

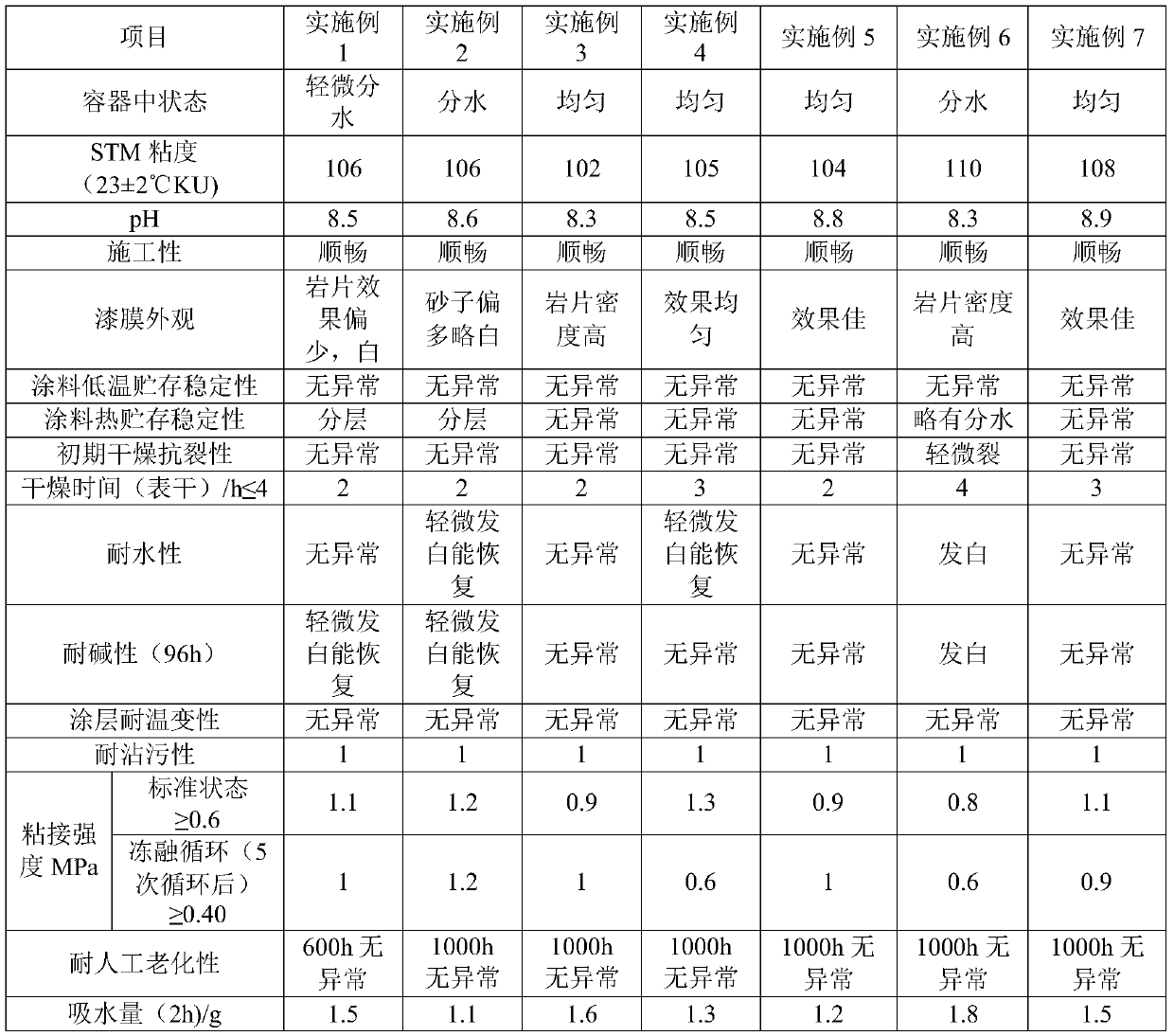

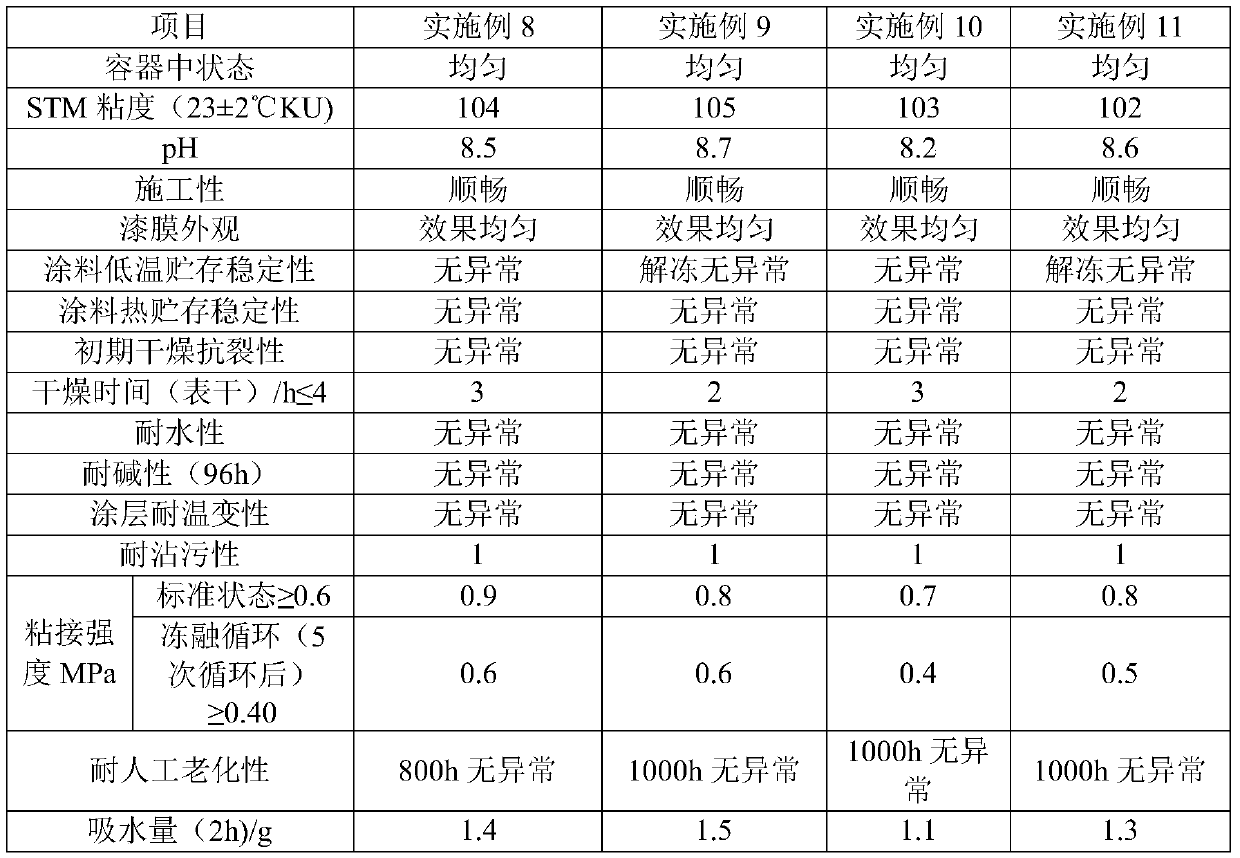

Examples

Embodiment 1

[0033] An ultra-thin composite rock flake real stone paint, which is obtained through the following processing steps:

[0034]Add 24kg of deionized water A and 1kg of PT-XL19 magnesium aluminum silicate thixotropic lubricant into the mixing tank, start the mixer, and stir at a high speed of 1200r / min for half an hour until the magnesium aluminum silicate thixotropic lubricant is fully dissolved , standing for 12h, to obtain the mixture A;

[0035] Transfer the mixture A into a paddle mixer, add 17.4kg of deionized water B, and at a speed of 80r / min, add 200g of preservative LX150, 800g of antifreeze, 100g of NXZ defoamer, and film-forming aids in sequence 1.2kg and Dow AMP-95 100g, stir evenly to obtain mixture B; at a speed of 30r / min, add 10kg of ultra-thin composite rock slices through a 10mm×10mm mesh screen, control the speed well, and avoid adding rock slices too quickly , it is too late to stir into the liquid material and agglomerate to obtain the mixture B;

[0036]...

Embodiment 2

[0038] An ultra-thin composite rock flake real stone paint, which is obtained through the following processing steps:

[0039] Add 15kg of deionized water A and 600g of PT-XL19 magnesium aluminum silicate thixotropic lubricant into the mixing tank, start the mixer, and stir at a high speed of 1500r / min for half an hour until the magnesium aluminum silicate thixotropic lubricant is fully dissolved , standing for 20h, to obtain the mixture A;

[0040] Transfer the mixture A into a paddle mixer, add 19.57kg of deionized water B, and at a speed of 100r / min, add 150g of preservative LX150, 700g of antifreeze, 200g of NXZ defoamer, and film-forming aids in sequence 1.4kg and Dow AMP-9580g, stir evenly to obtain mixture B; at the speed of 40r / min, add 17kg of ultra-thin composite rock slices through a 10mm×10mm mesh screen, control the speed well, and avoid adding rock slices too quickly , it is too late to stir into the liquid material and agglomerate to obtain the mixture B;

[0...

Embodiment 3

[0043] The processing operation of the real stone paint of embodiment 3 is the same as that of embodiment 2, the difference is that the content of each raw material is different, specifically: ultra-thin composite rock slice 18kg, pure acrylic emulsion 20kg, deionized water A 20kg, deionized water B 18.4kg, quartz Sand 20kg, preservative LX150 150g, antifreeze 800g, NXZ defoamer 200g, film-forming aid 1.2kg, PT-XL19 magnesium aluminum silicate thixotropic lubricant 800g, Dow AMP-9550g and TT-615 thickener 400g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com