Waterborne metal coating and preparation method thereof

A water-based metal coating and water-based acrylic technology, used in anti-corrosion coatings, coatings, etc., can solve problems such as good corrosion resistance, and achieve the effects of good adhesion, reduced pollution, and fast drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

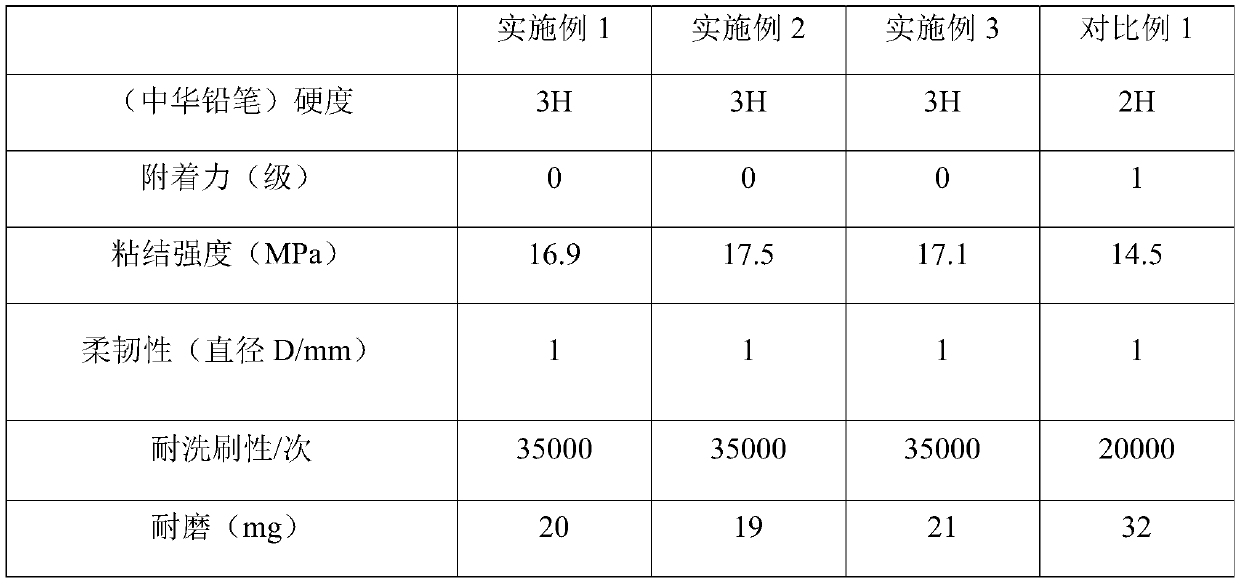

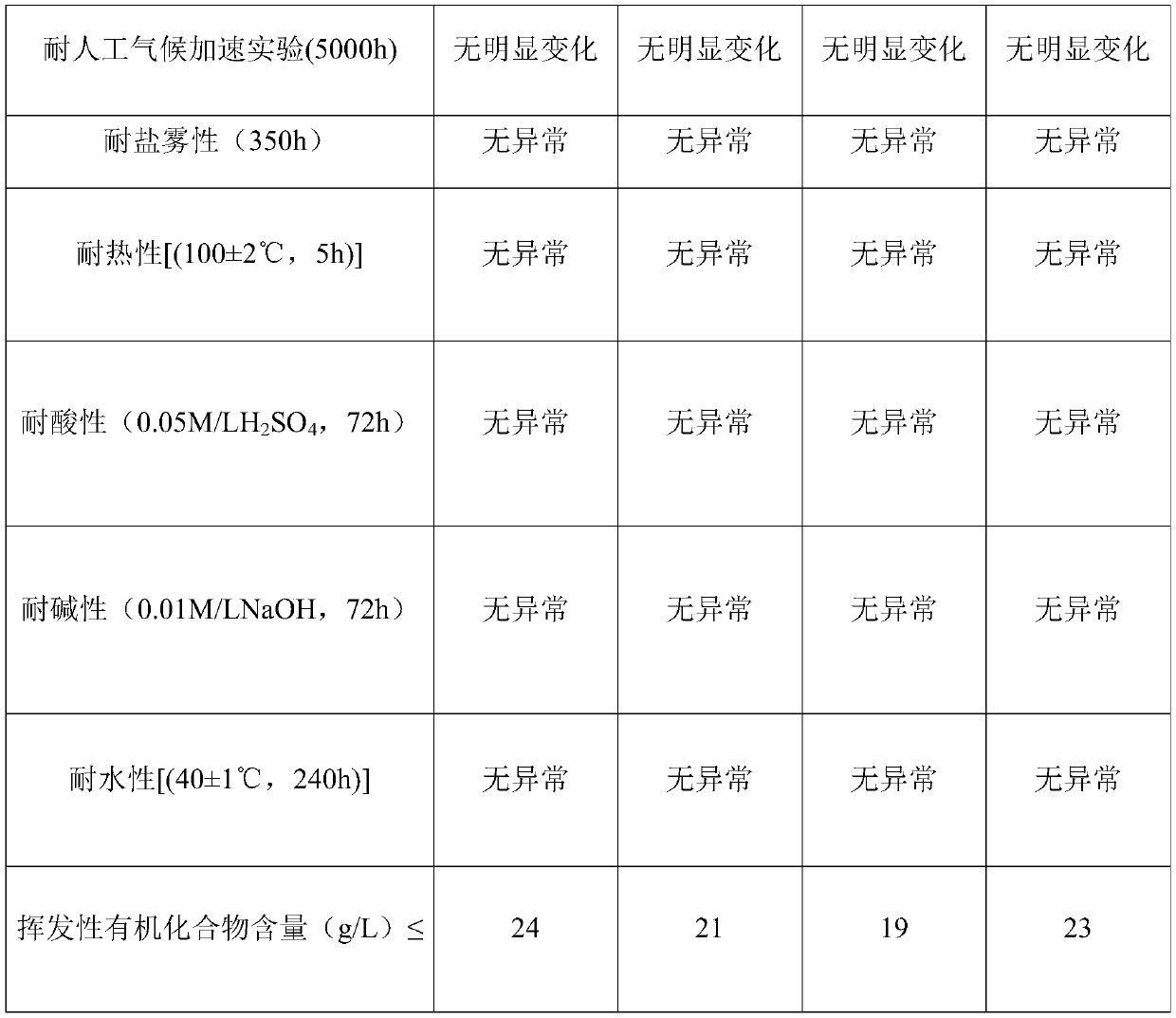

Examples

Embodiment 1

[0048] An embodiment of the present invention provides a water-based metal coating, which includes the following raw material components in parts by mass: 30 parts of water-based acrylic resin, 70 parts of nano-titanium silicon carbide modified acrylic resin, 20 parts of pigment, 0.8 parts of rheology additive, pH Conditioner 0.1 part, defoamer 0.8 part, film-forming aid 3 parts, anti-flash rust agent 0.8 part, co-solvent 8 parts, wetting and dispersing agent 2 parts, substrate wetting agent 0.5 part, thickener 1 part and 20 parts of deionized water.

[0049] Wherein, the water-based acrylic emulsion is DSM's A639; the rheology additive is Gaotai's 2025; the pigment is rutile titanium dioxide R-996; the pH regulator is N,N-dimethyl Ethanolamine; Described defoamer is FoamStarA10; Described film-forming aid is the mixture of tripropylene glycol methyl ether and dipropylene glycol butyl ether that mass ratio is 2:1; Described anti-flash rust agent is the Halox515 anti-flash rust...

Embodiment 2

[0061] An embodiment of the present invention provides a water-based metal coating, which includes the following raw material components in parts by mass: 40 parts of water-based acrylic resin, 45 parts of nano-titanium silicon carbide modified acrylic resin, 25 parts of pigment, 1.0 part of rheology additive, pH 0.2 parts of conditioner, 0.5 parts of defoamer, 3.5 parts of film-forming aid, 0.2 parts of anti-flash rust agent, 10 parts of co-solvent, 3 parts of wetting and dispersing agent, 1 part of substrate wetting agent, 2 parts of thickener and 18 parts of deionized water.

[0062] The trade mark of above-mentioned each component is identical with embodiment 1, and difference is: described film-forming aid is the mixture of tripropylene glycol methyl ether and dipropylene glycol butyl ether that mass ratio is 1:1; Described cosolvent is that mass ratio is 1:1 mixture of ethylene glycol butyl ether and propylene glycol methyl ether.

[0063] Wherein, the nano-titanium sil...

Embodiment 3

[0072] An embodiment of the present invention provides a water-based metal coating, comprising the following raw material components in parts by mass: 50 parts of water-based acrylic resin, 20 parts of nano-titanium silicon carbide modified acrylic resin, 15 parts of pigment, 0.5 part of rheology additive, pH 0.15 parts of conditioner, 0.6 parts of defoamer, 4 parts of film-forming aid, 0.6 part of anti-flash rust agent, 5 parts of co-solvent, 4 parts of wetting and dispersing agent, 0.8 part of substrate wetting agent, 1.5 parts of thickener and 15 parts of deionized water.

[0073] The trade mark of above-mentioned each component is identical with embodiment 1, and difference is: described film-forming auxiliary agent is the mixture of tripropylene glycol methyl ether and dipropylene glycol butyl ether that mass ratio is 3:1; Described auxiliary solvent is ethylene glycol butyl ether.

[0074] Wherein, the nano-titanium silicon carbide modified acrylic resin includes the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com