Sperm sorting device

A sorting device and sperm technology, which is applied in the interdisciplinary field of micro-nano processing and life sciences, can solve the problems of uneven hole size, low porosity, and affecting the sorting effect of sperm sorting devices, and achieve improved sorting efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The preparation of polydimethylsiloxane (PDMS) through-hole membrane comprises the following steps:

[0070] First, the S1813 photoresist was spin-coated on the silicon wafer substrate, the spin-coating speed was 3000rpm, the spin-coating time was 40s, and the spin-coating thickness was 1 μm. Then, it was baked and cured at 115° C. for 90 s. Afterwards, a UV lithography machine (SUSS MA6) is used for pan exposure, and the pan exposure time is 9s, and a photoresist layer with sufficient chain scission can be obtained.

[0071] The prepared photoresist layer is subjected to surface O in a glue remover. 2 Plasma treatment, O 2 The flow rate is 30sccm, the radio frequency power is 30w, and the processing time is 2min. Then, spin-coat the PDMS film layer on the surface of the treated photoresist layer, wherein the PDMS glue solution that is spin-coated is SYLGARD 184 produced by Dow Corning. This product is a package product composed of PDMS prepolymer and curing agent. ...

Embodiment 2

[0077] (1) Sperm sorting device

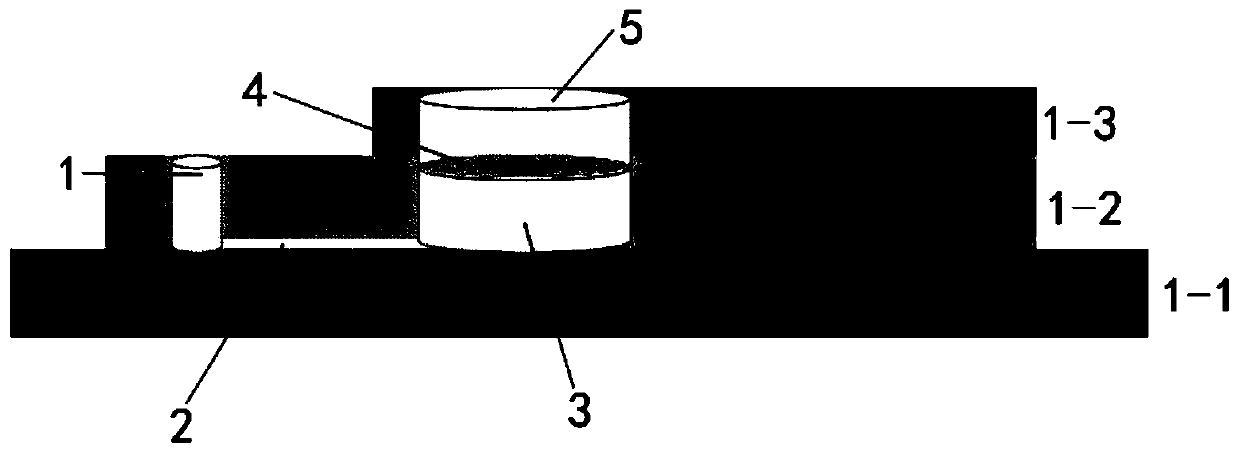

[0078] This embodiment provides a figure 1 The sperm sorting device with the structure shown includes: a semen inflow channel 2 and a semen cavity. Wherein, the semen cavity is divided into upper and lower two chambers by the horizontally arranged polydimethylsiloxane through-hole membrane 4 (made in Example 1), the lower chamber is the semen storage chamber 3, and the upper chamber is the semen storage chamber 3. Semen recovery chamber 5 ; one end opening of the semen inflow channel 2 serves as the semen inlet 1 , and the other end opening communicates with the semen storage chamber 3 .

[0079] In this embodiment, the semen inlet 1, the semen inflow channel 2 and the semen storage chamber 3 are located in the first polymer layer 1-2, and the material of the first polymer layer 1-2 is polydimethylsiloxane; semen recovery The chamber 5 is located in the second polymer layer 1-3, and the material of the second polymer layer 1-3 is polydimethy...

Embodiment 3

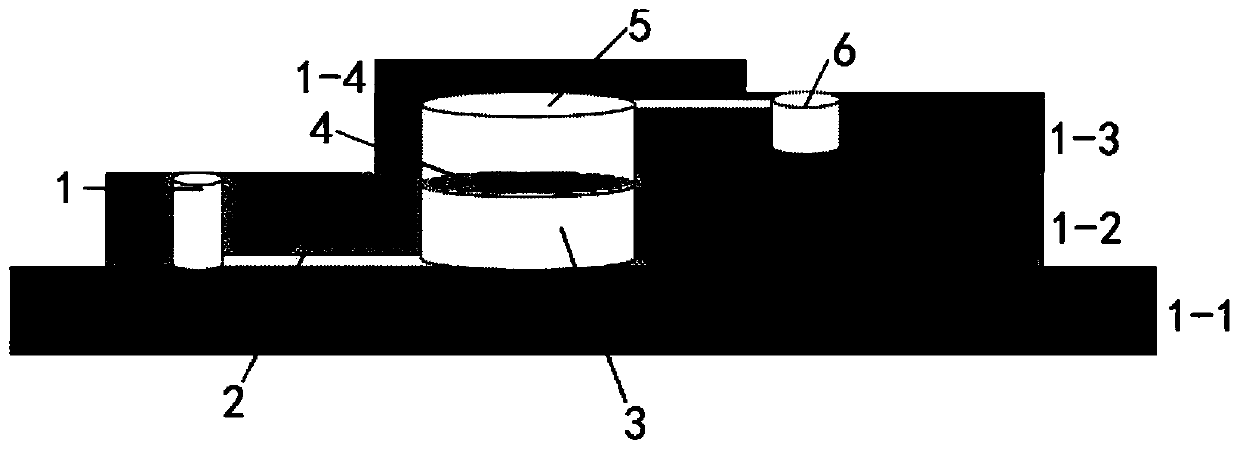

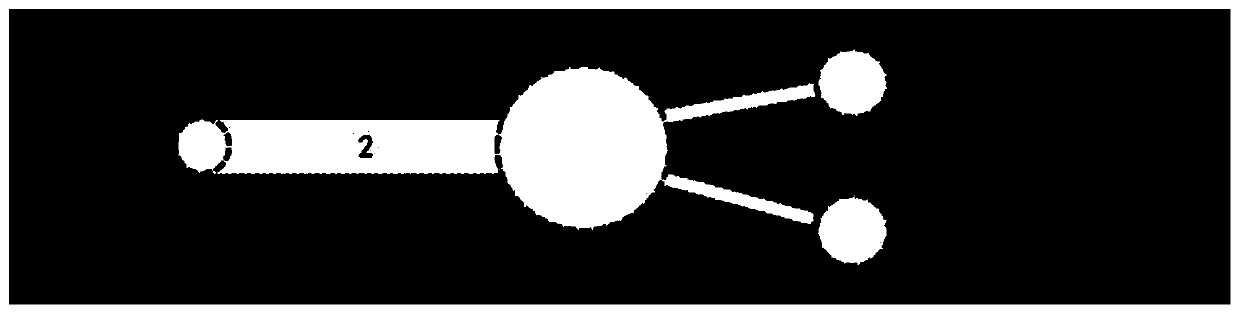

[0087] Chemotactic sperm sorting device

[0088] This embodiment provides a figure 2 and image 3 The sperm sorting device with the structure shown includes: a semen inflow channel 2, a semen cavity, a first chemotaxis sorting channel 6-1 and a chemotaxis sorting second channel 6-2. Wherein, the semen cavity is divided into upper and lower two chambers by the horizontally arranged polydimethylsiloxane through-hole membrane 4 (made in Example 1), the lower chamber is the semen storage chamber 3, and the upper chamber is the semen storage chamber 3. Semen recovery chamber 5; one end opening of semen inflow channel 2 serves as semen inlet 1, and the other end opening communicates with semen storage chamber 3; chemotaxis sorting first channel 6-1 and chemotaxis sorting second channel The opening at one end of 6-2 communicates with the semen recovery chamber 5, and the opening at the other end serves as the exit 6 of the chemotaxis sorting channel; cumulus cells are cultivated i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com