Flue gas desulfurization tower and flue gas dust removal and desulfurization and wastewater treatment process

A technology for desulfurization towers and flue gas, which is applied in the fields of flue gas desulfurization towers, flue gas dedusting, desulfurization and wastewater treatment, and can solve the problems of catalytic devices and coal-fired boilers that cannot be upgraded, shut down or demolished and rebuilt, and have too many equipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

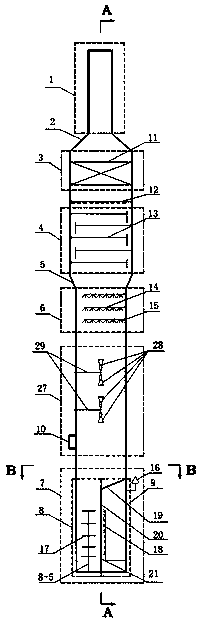

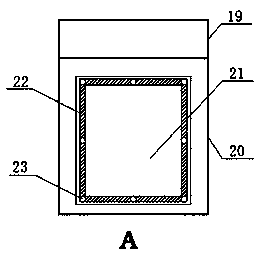

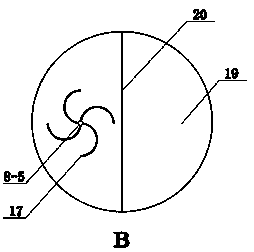

[0071] A flue gas desulfurization tower, from top to bottom is a flue gas discharge area 1, a demister area 3, a tower area 4, a spray area 6, a rapid cooling area 27, and a waste water treatment area 7, and the flue gas discharge area 1 and The defogging zone 3 is connected by a cone-shaped variable diameter 2, the tower plate zone 4 is below the defogging zone 3, the tower plate zone 4 and the spray zone 6 are connected by an inverted cone-shaped variable diameter 5, and the quenching cooling zone is below the spray zone 6 27. Below the rapid cooling zone 27 is the wastewater treatment zone 7.

[0072]The demister 11 described in CN201621043983.8 is set in the demister area 3, the liquid distributor 12 is arranged under the demist area 3, the tray area 4 is arranged under the liquid distributor 12, and a total of 4 layers of towers are arranged in the tray area 4 Plate, select sieve tray; Spray area 6 is provided with 3 layers of spray pipelines 14 in total, the distance bet...

Embodiment 2

[0081] The flue gas volume of an enterprise is 220000Nm 3 / h, the flue gas temperature is 145°C, the pressure is 4.5kPa, where SO 2 The concentration is 1200mg / Nm 3 , Dust concentration is 260mg / Nm 3 , using the flue gas desulfurization tower of the present invention, the clean water flow rate in the quenching cooling zone is 80 m 3 / h. SO in exhaust flue gas 2 The content is measured by German Testo flue gas analyzer (model Testo-350). The dust content is measured according to GB / T 16157-1996 "Sampling Method for Particulate Matter and Gaseous Pollutants in Exhaust from Stationary Pollution Sources". The gas is filtered, dissolved in water, and the salt content is measured and calculated according to HJ / T51-1999 "Gravimetric Method for Determination of Total Salt in Water Quality". After measurement and calculation, the temperature of the flue gas entering the chimney is 50 °C, SO 2 The concentration is 11.6mg / Nm 3 , Dust content is 9.3mg / Nm 3 , soluble salt content is...

Embodiment 3

[0083] Close the valve that enters the 27 clean water pipelines in the rapid cooling and cooling zone, and adjust the clean water flow to 0m 3 / h, all the other are the same as embodiment 2, the flue gas temperature that enters the chimney is 51 ℃, SO 2 The content is 14.8mg / Nm 3 , Dust content is 21.3mg / Nm 3 , soluble salt content is 9.4mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com