A kind of preparation method of phosphorus doped carbon nitride

A carbon nitride and phosphorus doping technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of insufficient photocatalytic performance and low visible light absorption, and achieve improved photocatalytic performance. Excellent performance, high visible light absorption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A phosphorus-doped carbon nitride, using nitrogen-rich organic matter melamine as the carbon nitride precursor, red phosphorus as the phosphorus source, first prepared block carbon nitride by conventional calcination, and then by combining carbon nitride and phosphorus The mixing and grinding of simple substances makes phosphorus doped into the molecular structure of carbon nitride, and finally the undoped phosphorus is removed by roasting. It is prepared according to the following steps:

[0020] 1) First put the carbon nitride precursor melamine into the ceramic crucible, cover the lid, put it into the muffle furnace, heat it up to 550°C at a heating rate of 2°C / min and keep it roasted for 3 hours, then cool it naturally Obtain massive carbon nitride;

[0021] 2) Add red phosphorus to the above block carbon nitride so that the mass ratio of carbon nitride to red phosphorus is 1:1, and put it into a stainless steel grinding tank according to the mass ratio of grinding ...

Embodiment 2

[0023] A phosphorus-doped carbon nitride, using dicyandiamide as carbon nitride to prepare a precursor, yellow phosphorus as a phosphorus source, prepared according to the following steps:

[0024] 1) First put the carbon nitride precursor dicyandiamide into the ceramic crucible, cover the lid, put it into the muffle furnace, heat it to 600°C at a heating rate of 5°C / min and keep it roasted for 3 hours. After cooling, block carbon nitride is obtained;

[0025] 2) Add yellow phosphorus to the above block carbon nitride, so that the mass ratio of carbon nitride and yellow phosphorus is 1:2, and put it into the zirconia grinding jar according to the mass ratio of grinding balls and carbon nitride as 1:200 , after grinding for 60 hours at a speed of 25 Hz, phosphorus-doped carbon nitride can be obtained.

Embodiment 3

[0027] A phosphorus-doped carbon nitride is prepared by using urea as a precursor for carbon nitride, black phosphorus as a phosphorus source, and is prepared according to the following steps:

[0028] 1) Put urea, the precursor of carbon nitride, into a ceramic crucible, cover it, put it into a muffle furnace, heat it to 500°C at a heating rate of 10°C / min and keep it roasted for 5 hours. After natural cooling, the Obtain massive carbon nitride;

[0029] 2) Add black phosphorus to the above block carbon nitride so that the mass ratio of carbon nitride to black phosphorus is 1:5, and put it into the agate grinding jar according to the mass ratio of grinding balls to carbon nitride as 1:50, After grinding for 30 hours at a rotational speed of 50 Hz, phosphorus-doped carbon nitride can be obtained.

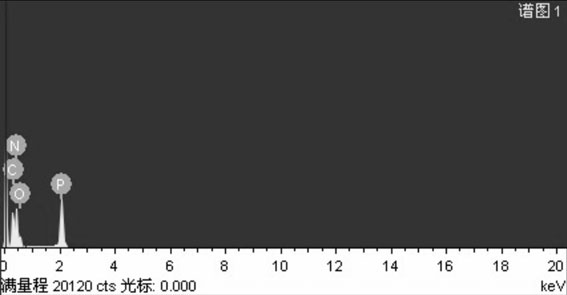

[0030] The EDS analysis figure of the phosphorus-doped carbon nitride prepared by the method of the present invention is as follows figure 1 , the figure proves that phosphorus el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com