Preparation method and application of carbonized silk photocatalyst

A photocatalyst and photocatalytic reaction technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of less active functional groups and low photocatalytic activity, and achieve mild reaction conditions and preparation The process is simple and the effect of reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

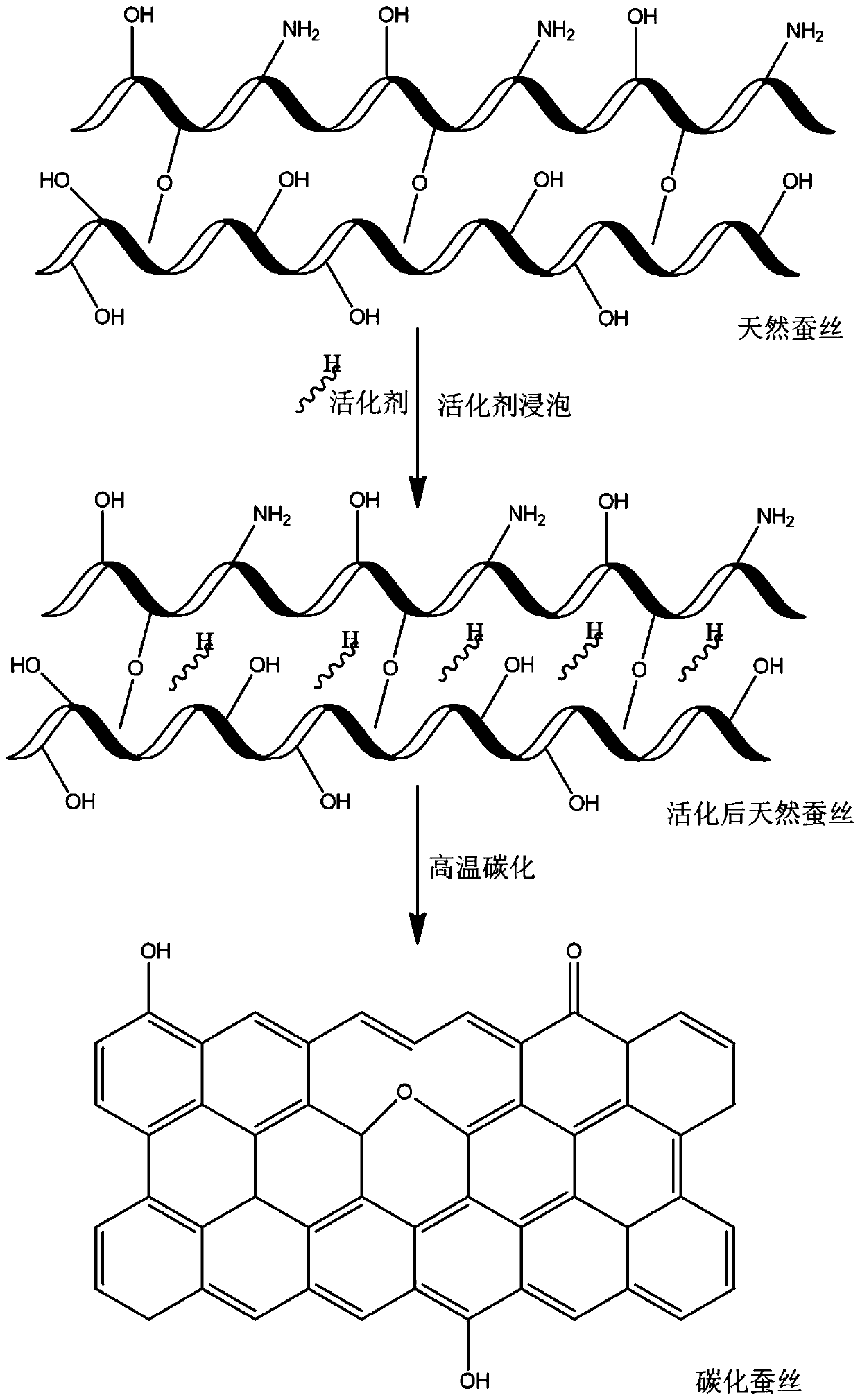

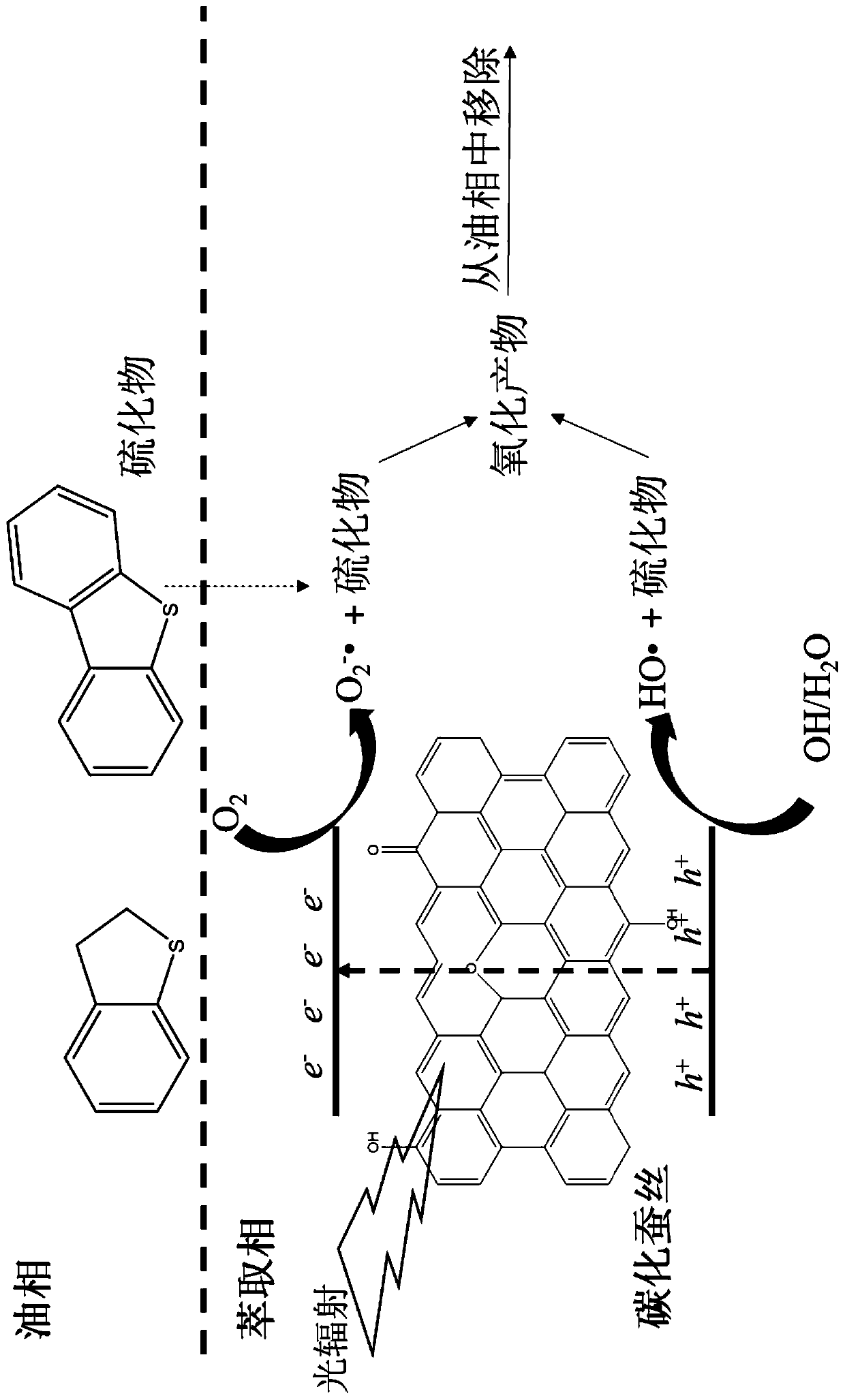

Method used

Image

Examples

preparation Embodiment 1

[0049] Rinse the natural cocoon with deionized water 3 times to wash off the impurities on the surface of the cocoon. Then cut the washed silkworm cocoons into an area of about 1cm 2 (1 cm x 1 cm) pieces. Soak 1g flake silk and 0.1g phosphotungstic acid in 100mL deionized water for 24 hours, take out the soaked silk and dry it in a vacuum oven at 40°C for 24 hours. Continue to place the dried silk in a tube furnace, which is fed with argon gas at a flow rate of 5 mL / min. The tube furnace was heated from room temperature to 700 °C at a rate of 5 °C / min, and fired at 700 °C for 4 hours, and naturally cooled to room temperature to obtain carbonized silk activated by phosphotungstic acid. Finally, it was rinsed with distilled water and ethanol three times to remove the residual activator on the surface, and the sample was named LWS-700.

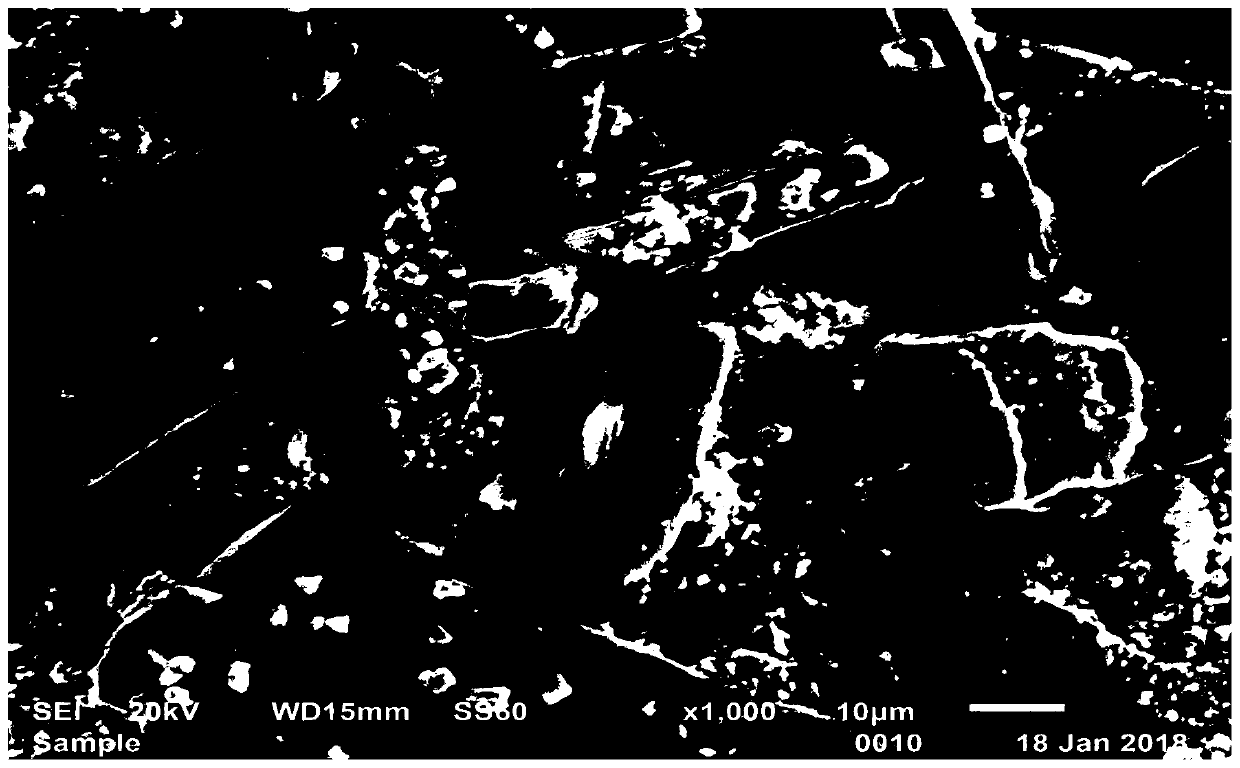

[0050] The characterization and analysis of the catalyst product made in this example, the scanning electron micrograph of the silk carboni...

preparation Embodiment 2

[0052] Rinse the natural cocoon with deionized water 3 times to wash off the impurities on the surface of the cocoon. Then cut the washed silkworm cocoons into an area of about 1cm 2 (1 cm x 1 cm) pieces. Soak 1g flake silk, 0.1g potassium chloride and 0.2g oxalic acid in 100mL deionized water for 18h, take out the soaked silk and dry in a vacuum oven at 40°C for 24h. Continue to place the dried silk in a tube furnace, and argon gas is introduced into the tube furnace, and the flow rate of argon gas is 10 mL / min. The tube furnace was heated from room temperature to 500 °C at a rate of 5 °C / min, and fired at 500 °C for 4 hours, and then naturally cooled to room temperature to obtain carbonized silk co-activated by potassium chloride and oxalic acid. Finally, rinse with distilled water and ethanol 3 times to remove the residual activator on the surface, and the sample is named KCS-500.

[0053] Characterization analysis is carried out to the catalyst product made in this ex...

preparation Embodiment 3

[0055] Rinse the natural cocoon with deionized water 3 times to wash off the impurities on the surface of the cocoon. Then cut the washed silkworm cocoons into an area of about 1cm 2 (1 cm x 1 cm) pieces. Soak 1g of flaky silk and 0.2g of boric acid in 100mL of deionized water for 24 hours, then take out the soaked silk and dry it in a vacuum oven at 40°C for 24 hours. Continue to place the dried silk in a tube furnace, which is fed with argon gas at a flow rate of 5 mL / min. The tube furnace was heated from room temperature to 500 °C at a rate of 5 °C / min, and fired at 500 °C for 4 hours, and naturally cooled to room temperature to obtain carbonized silk activated by boric acid. Finally, rinse with distilled water and ethanol 3 times to remove the residual activator on the surface, and the sample is named PS-500.

[0056] The catalyst product made in this example is characterized and analyzed, and the scanning electron microscope picture of the silk carbonized material (P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com