Oil removing ship for offshore oil leaking phenomenon

An offshore oil and oil tanker technology, applied in special-purpose ships, open water surface cleaning, grease/oily substance/float removal devices, etc. problems such as low level, to achieve the effect of improving oil removal efficiency, improving oil absorption efficiency, and high oil absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

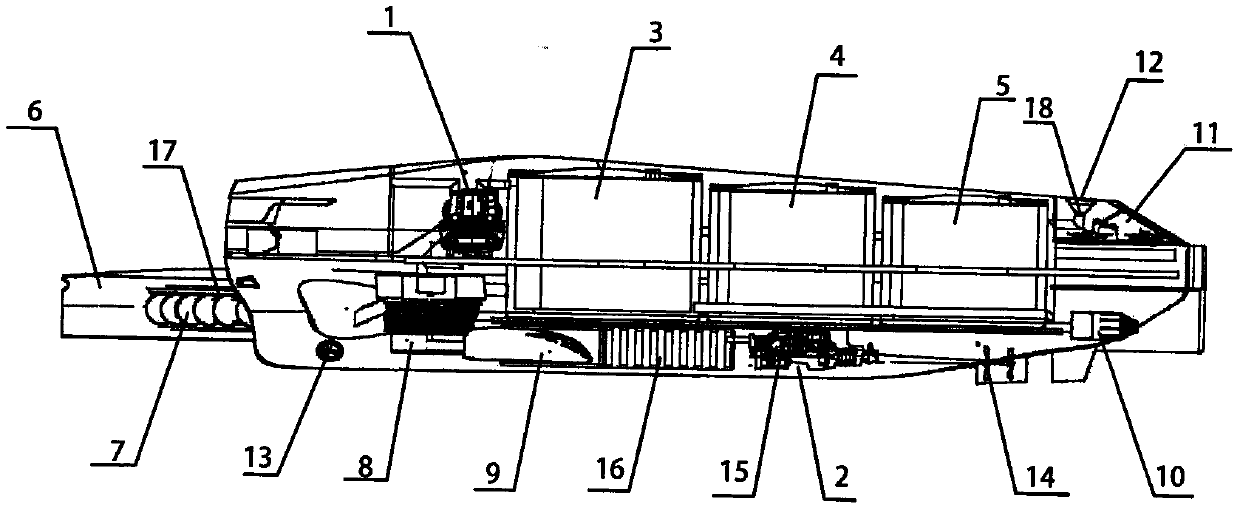

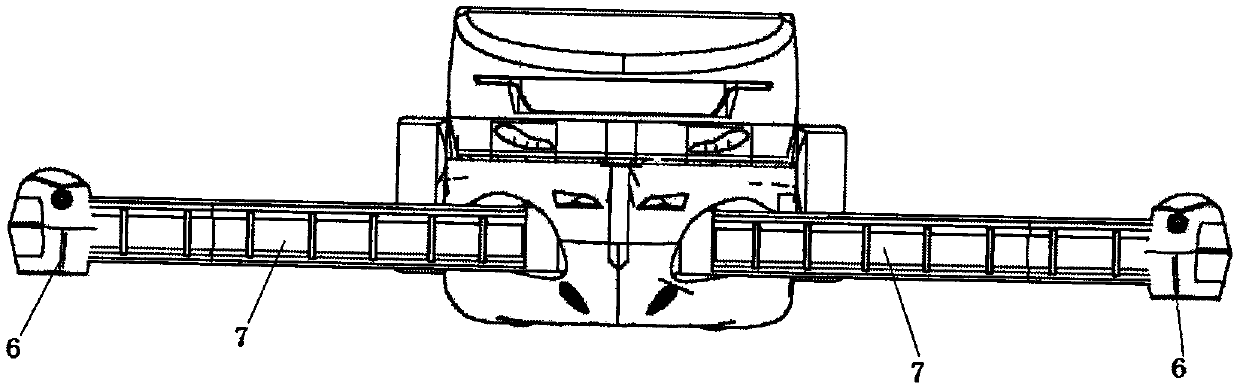

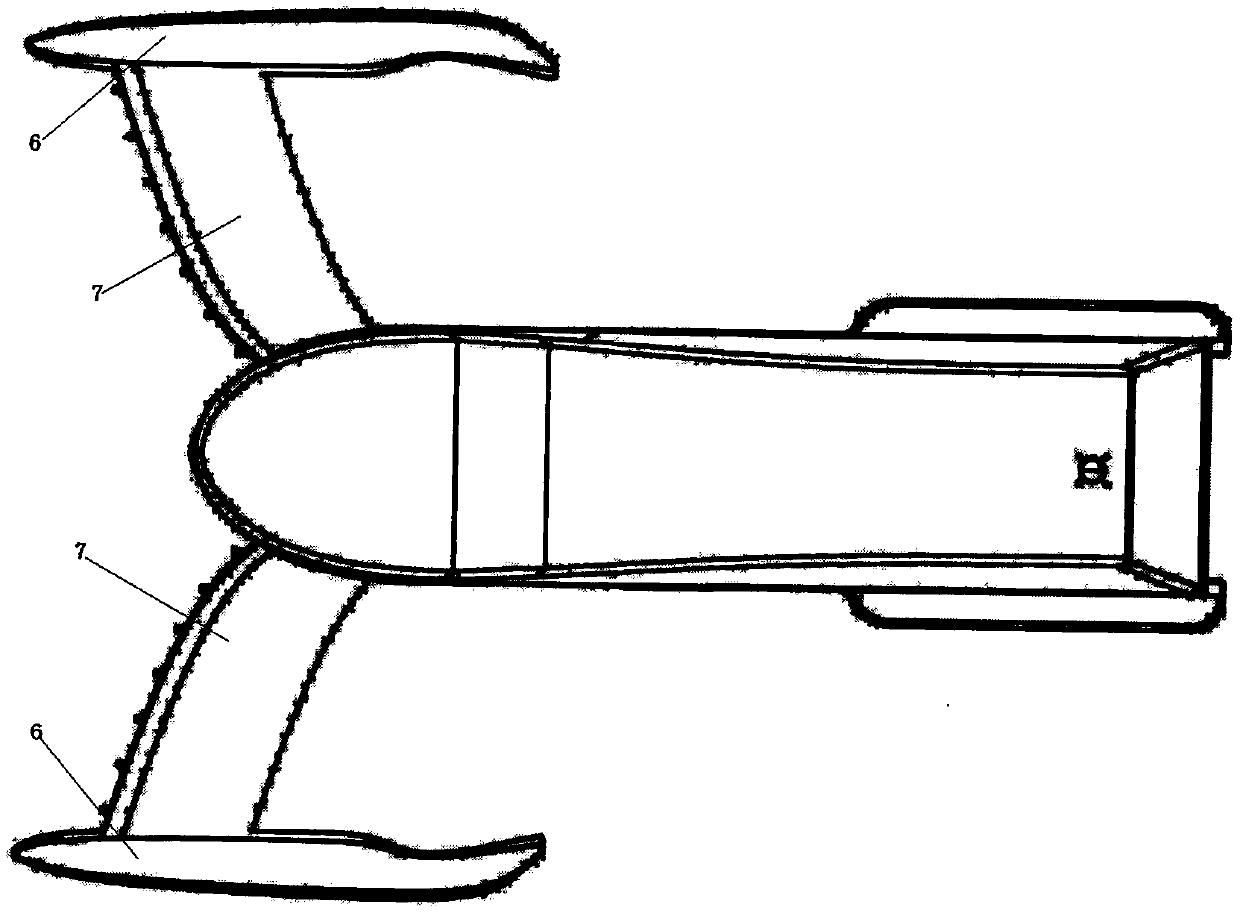

[0027] Embodiment: An oil removal ship for oil spills at sea, including a hull and a central machine room 1 installed on the hull, a main power unit 2, left and right wings 6, an oil storage device, and an oil-absorbing drum 7, an electrolytic oil-water Separator 8, bioreactor 9, sewage reactor, unmanned cabin 11, oil delivery port 12 and active sonar 13; said central machine room 1 is equipped with hull driving control system, propeller control device, oil storage tank control device, Hull oil suction and degreasing device control device and sonar device control system, the central machine room 1 is located in the core part of the entire hull, and is set at the front end of the oil removal ship. The central machine room 1 performs unified control of the hull system, which can achieve a high degree of automation. It should be explained Yes, the control of various systems of the hull by the central machine room 1 is a commonly used technical means in this technical field, and wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com