Preparation and construction method of CCW thermal insulation curtain wall separated concrete

A technology of concrete and thermal insulation curtain, applied in walls, building components, buildings, etc., can solve the problems that it is difficult to meet the performance requirements of the inner leaf load-bearing shear wall concrete and the outer leaf wall concrete at the same time, achieve good workability, improve Workability and guaranteed strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Concretely, a kind of preparation method of CCW thermal insulation curtain wall separation type concrete of the present invention comprises the following steps:

[0038] (1) Preparation of primary mixture

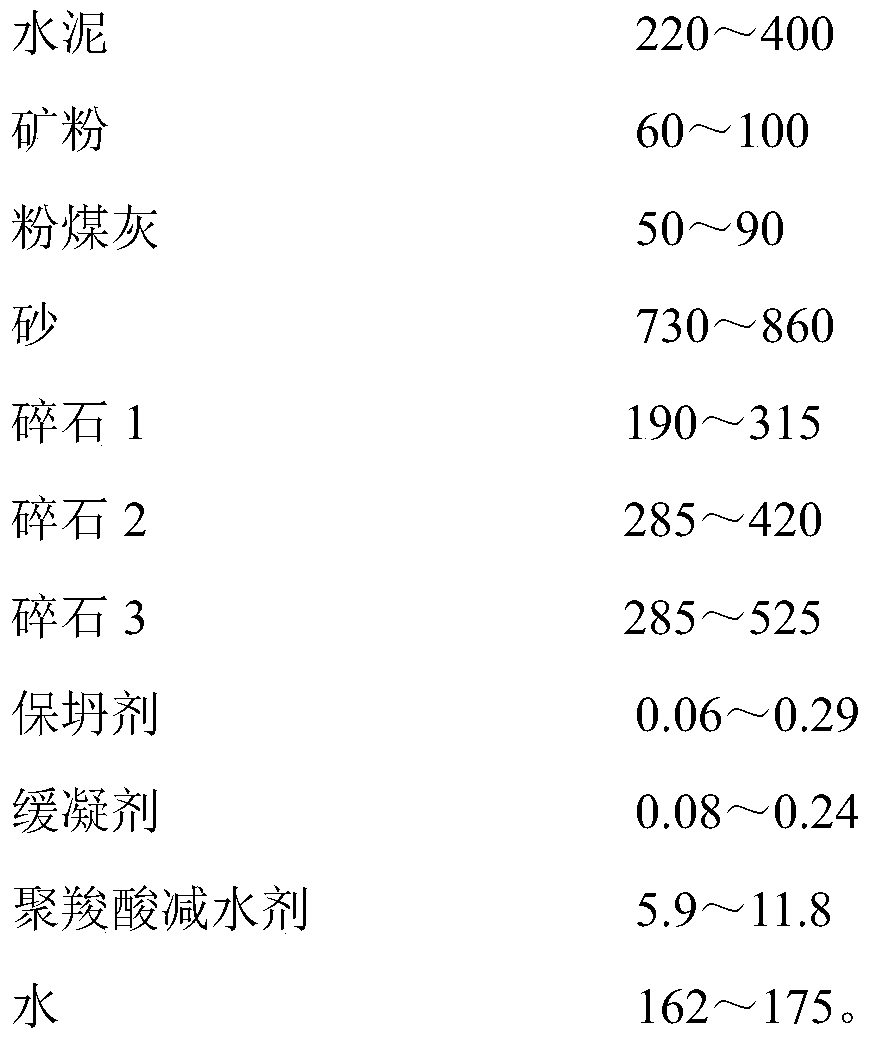

[0039] The components of the concrete are weighed and stirred according to the designed mixing ratio to obtain the primary mixture; the components of the concrete include cement, mineral powder, fly ash, sand, gravel, slump retaining agent, retarder, Polycarboxylate superplasticizer and water, wherein the crushed stones are composed of crushed stones with a particle size of 5-10mm 1, crushed stones with a particle size of 10-16mm 2, and crushed stones with a particle size of 10-31.5mm 3. The percentage is 20 %~30%: 30%~40%: 30%~50% mixed in proportion.

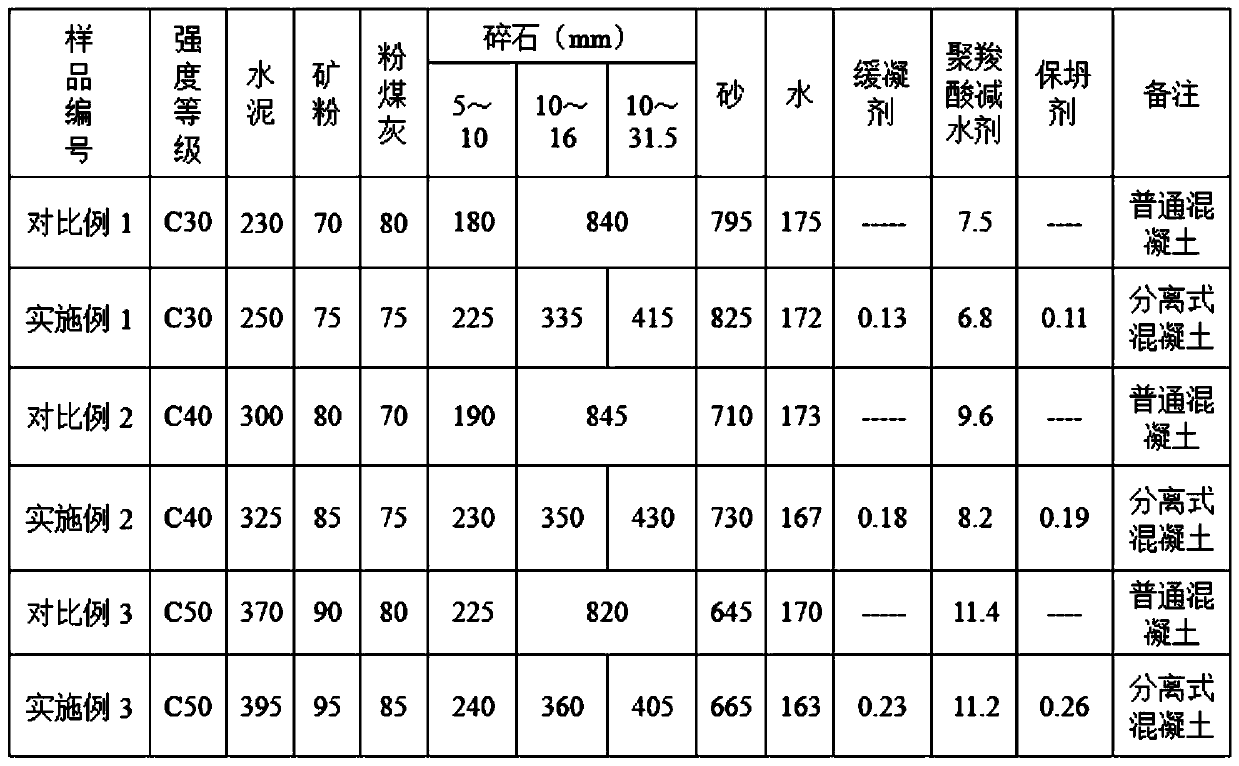

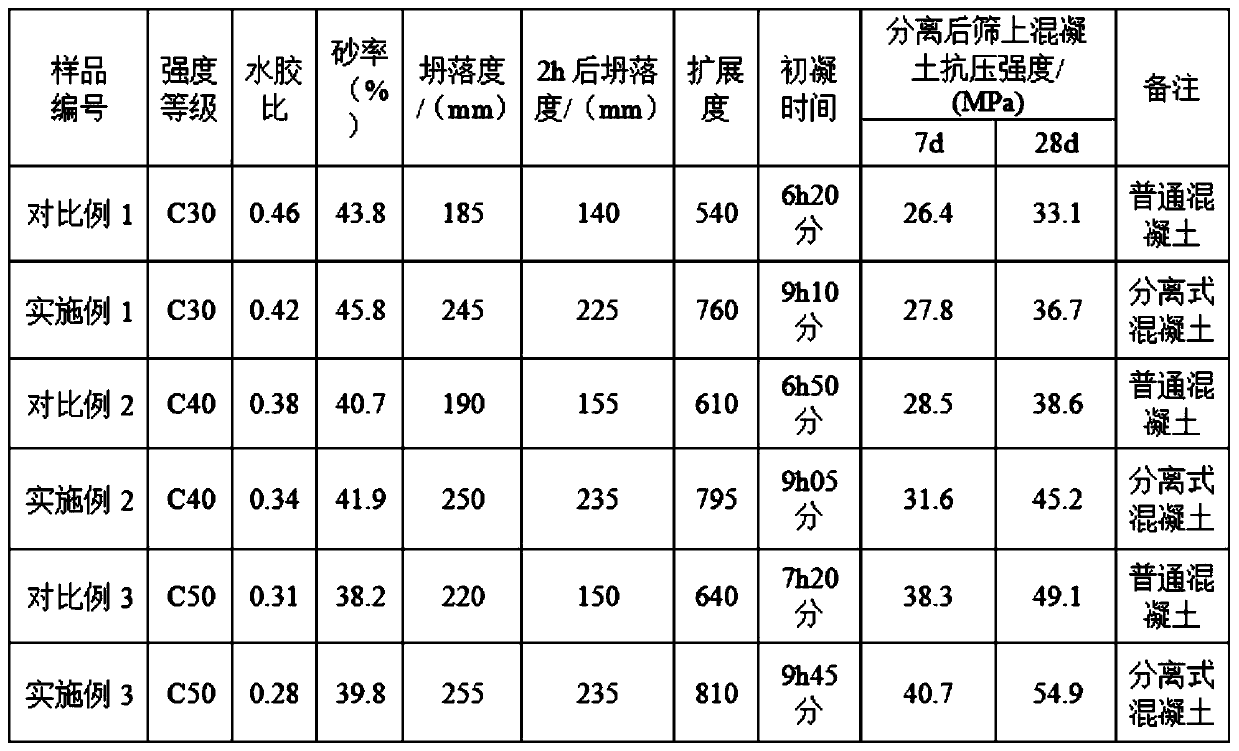

[0040] Each component in the primary mixture obtained above is composed by the following unit mass (kg / m 3 ):

[0041]

[0042]

[0043] The above cement is ordinary Portland cement with strength grade 42.5 ...

Embodiment 1

[0054] When preparing separated concrete according to the set strength level, the components of the concrete (ie cement, mineral powder, fly ash, sand, gravel, slump retaining agent, retarder, polycarboxylate superplasticizer and water) )according to figure 1 Weigh and stir the mixing ratio in the mixture to obtain the primary mixture, and detect the technical indicators such as primary mixture slump, expansion degree, initial setting time and slump loss; the primary mixture obtained after stirring is then left to stand for 1.5 Remix after 1 hour, and then sieve it through a string drum with a diameter of 125mm in a vibrating state. The sieve hole size is 12mm. room, measure the strength of 7d and 28d respectively, and adjust the mix ratio of the primary mixture according to the measured strength of the concrete on the screen according to the "Ordinary Concrete Mix Proportion Design Regulations" JGJ55-2011, that is, the mix of CCW insulation curtain wall separated concrete for...

Embodiment 2

[0058] When preparing separated concrete according to the set strength level, the components of the concrete (ie cement, mineral powder, fly ash, sand, gravel, slump retaining agent, retarder, polycarboxylate superplasticizer and water) )according to figure 1 Weigh and stir the mixing ratio in the mixture to obtain the primary mixture, and detect technical indicators such as primary mixture slump, expansion degree, initial setting time and slump loss; the primary mixture obtained after stirring is then left to stand for 2 Remix after 1 hour, and then sieve it through a string drum with a diameter of 125mm in a vibrating state. The sieve hole size is 12mm. room, measure the strength of 7d and 28d respectively, and adjust the mix ratio of the primary mixture according to the measured strength of the concrete on the screen according to the "Ordinary Concrete Mix Proportion Design Regulations" JGJ55-2011, that is, the mix of CCW insulation curtain wall separated concrete for pouri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com