Superparamagnetic electromagnetic composite material, preparation method thereof and high-sensitivity electromagnetic valve

An electromagnetic composite material and superparamagnetic technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of electromagnet hysteresis and sensitivity cannot be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

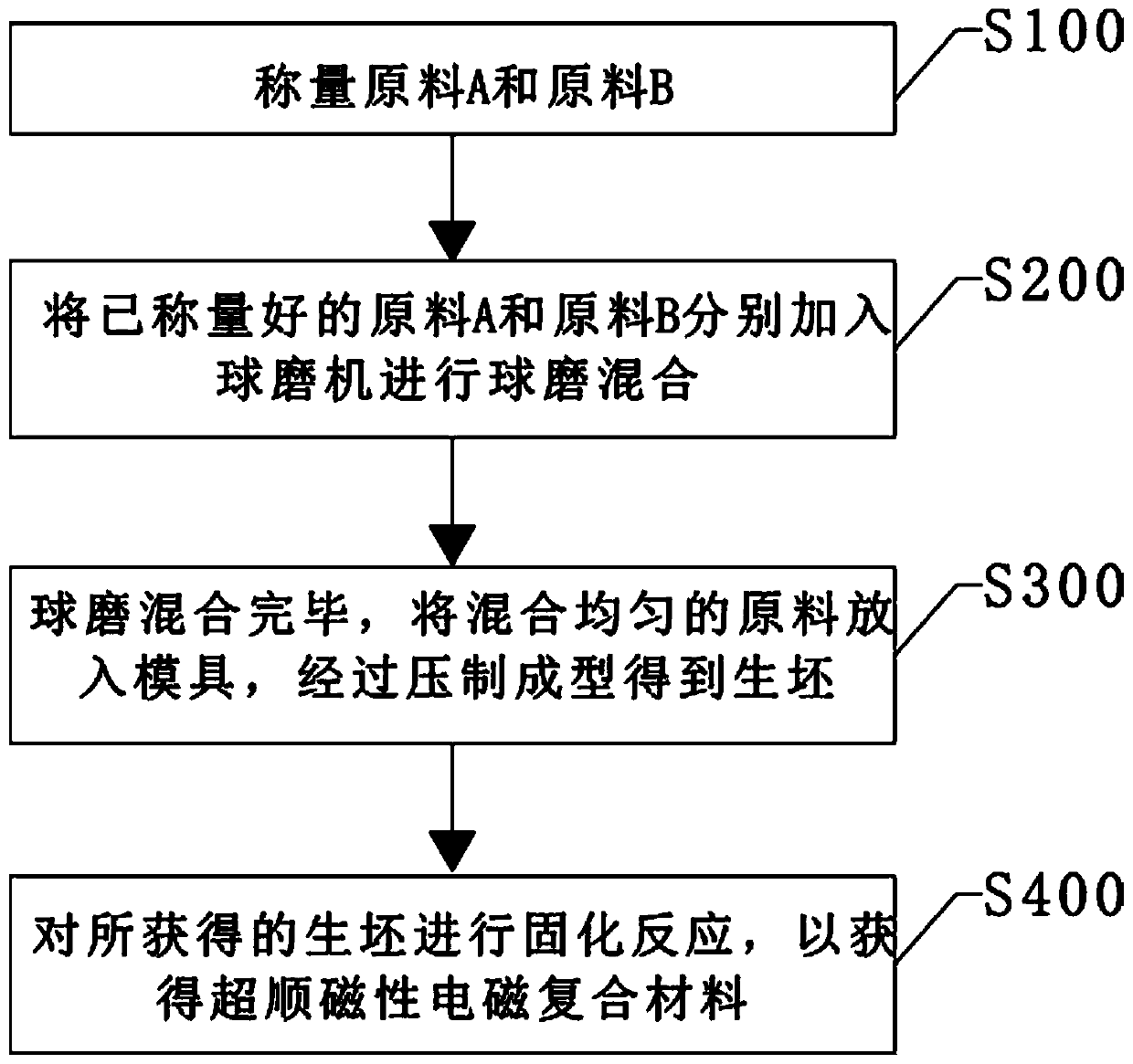

Method used

Image

Examples

Embodiment 1

[0046] Weigh 20g of black nano-ferric oxide powder and 180g of epoxy resin, and then add them together with 200g of zirconia balls into a ball mill for ball milling and mixing. The speed of the ball mill is 40r / min, and the ball milling time is 10h. Then, put the uniformly mixed powder into the mold and dry press to form it. The forming pressure is 5MPa. According to actual needs, it can be made into green parts in the shape of the static iron core and the moving iron core of the solenoid valve. Subsequently, put the obtained green parts into a resistance furnace for curing reaction, the curing temperature is 270 ° C, the time is 120 minutes, after curing, cool to room temperature, and the composite material made of nanometer ferroferric oxide / epoxy resin can be obtained. Solenoid valve parts, such as static iron core, moving iron core.

[0047] Assemble the solenoid valve parts to the solenoid valve for testing. The valve opening time is less than 2 seconds, and the valve clo...

Embodiment 2

[0049]Weigh 60g of black nanometer iron ferric oxide powder and 140g of epoxy resin, and then add them together with 200g of zirconia balls into a ball mill for ball milling and mixing. The speed of the ball mill is 45r / min, and the ball milling time is 10h. Then, put the uniformly mixed powder into the mold and dry press to form it. The forming pressure is 15 MPa. According to actual needs, it can be made into green parts in the shape of the static iron core and the moving iron core of the solenoid valve. Subsequently, put the obtained green part into a resistance furnace for curing reaction, the curing temperature is 270 ° C, the time is 100 min, and after curing, it is cooled to room temperature, and the composite material made of nanometer ferroferric oxide / epoxy resin can be obtained. Solenoid valve parts, such as static iron core, moving iron core.

[0050] Assemble the solenoid valve parts to the solenoid valve for testing. The valve opening time is less than 2 seconds,...

Embodiment 3

[0052] Weigh 100g of black nanometer iron ferric oxide powder and 100g of epoxy resin, and then add them together with 200g of zirconia balls into a ball mill for ball milling and mixing. The speed of the ball mill is 45r / min, and the ball milling time is 15h. Then, put the uniformly mixed powder into the mold and dry press to form it. The forming pressure is 20 MPa. According to actual needs, it can be made into green parts in the shape of the static iron core and the moving iron core of the solenoid valve. Subsequently, put the obtained green parts into a resistance furnace for curing reaction, the curing temperature is 180 ° C, the time is 90 minutes, after curing, cool to room temperature, and the composite material made of nanometer ferroferric oxide / epoxy resin can be obtained. Solenoid valve parts, such as static iron core, moving iron core.

[0053] Assemble the solenoid valve parts to the solenoid valve for testing. The valve opening time is less than 2 seconds, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com