A dicyclocene cobalt cation-based water-based polyurethane and corrosion inhibitor system and preparation method

It is a kind of dicene cobalt anode and water-based technology, which is applied in the field of chemical anti-corrosion, which can solve environmental pollution and other problems, and achieve the effect of high-efficiency polymerization and anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

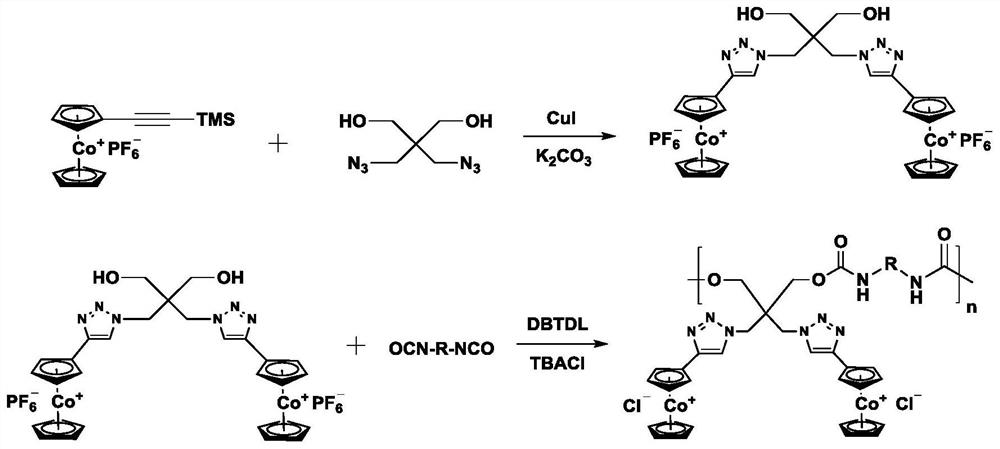

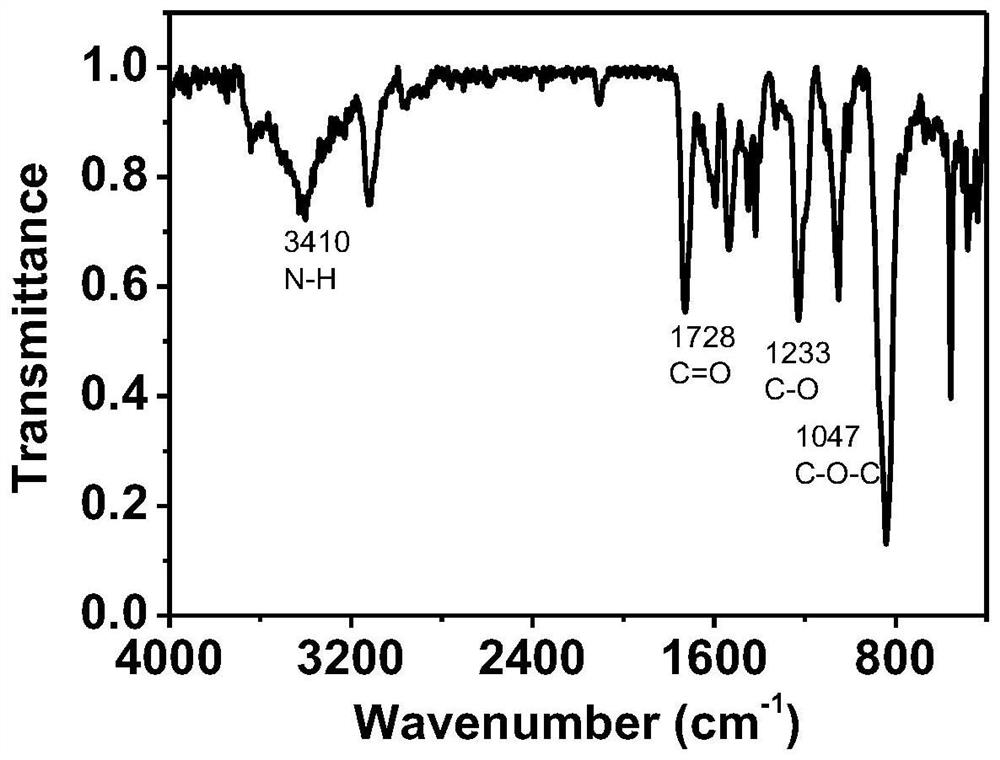

[0050] The preparation method of the dihydrocene cobalt cation derivative represented by general formula I, according to figure 1 The compound reacts according to the specified route to obtain one of the following general formulas:

[0051]

[0052] Where: R=-C 6 h 12 ,-C 7 h 6 ,-C 10 h 18 ,-C 13 h 22 .

Embodiment 1

[0053] Embodiment 1: when R=-C 6 h 12 , Preparation of X=Cl

[0054] Dissolve 1 to 5 parts of trimethylsilyl-protected ethynyl cobaltocene hexafluorophosphate and 1 to 10 parts of bis-azido-neopentyl glycol in 20 to 50 mL of anhydrous acetonitrile, and purify oxygen with nitrogen for 30 minutes to obtain solution A ; At the same time, add 0.1 to 1.2 parts of catalyst in another round-bottomed flask, pass nitrogen to remove oxygen for 5-60min, and obtain solution B; the catalyst is CuI or CuBr; then solution A is transferred to solution B under nitrogen protection , after 5-30min, add 1-20 parts of finely ground anhydrous potassium carbonate K 2 CO 3 , react for 10-48 hours under the protection of nitrogen at 25-90°C to obtain a suspension; filter the reacted suspension, wash with acetonitrile, and then concentrate by rotary evaporation to obtain a concentrated solution; add the concentrated solution dropwise to diethyl ether, collect the precipitate, and finally pass After...

Embodiment 2

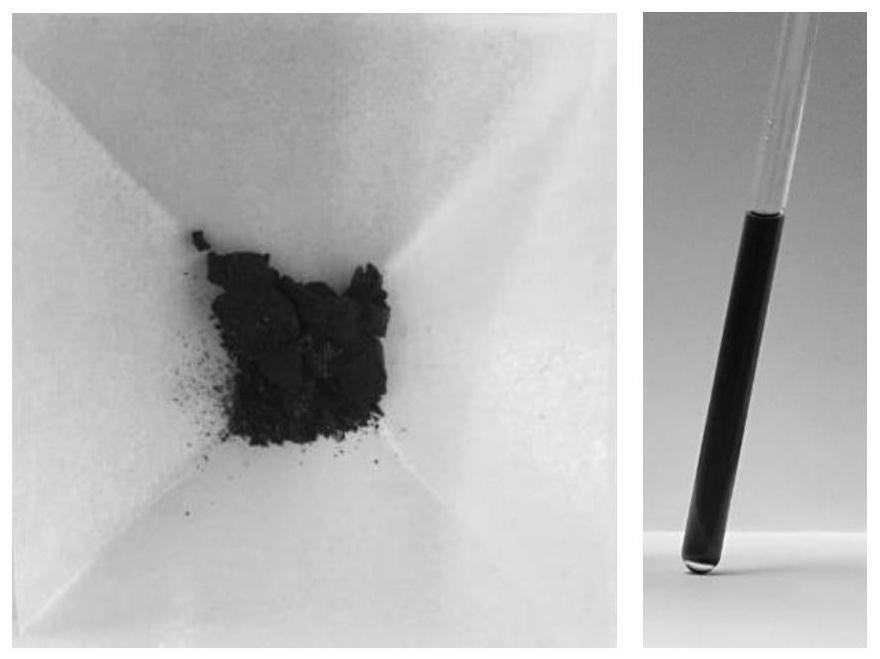

[0063] The concentration of hydrochloric acid solution is 4.0mol / L, the dosage of hydrochloric acid solution is 150mL, the dosage of cobaltocene-based waterborne polyurethane (PU-HDI) is 20mg / L, and 10# steel is immersed in the acid solution at 25°C for 2-6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com