Double-electric-layer capacitive flexible pressure sensor with enhanced inclined structure and manufacturing method

A technology of electric double layer capacitance and pressure sensor, which is applied in the field of sensors, can solve problems such as poor mechanical properties, device sensitivity drop, nonlinearity, etc., and achieve the effects of avoiding irreversible deformation, large test range, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The manufacturing method of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

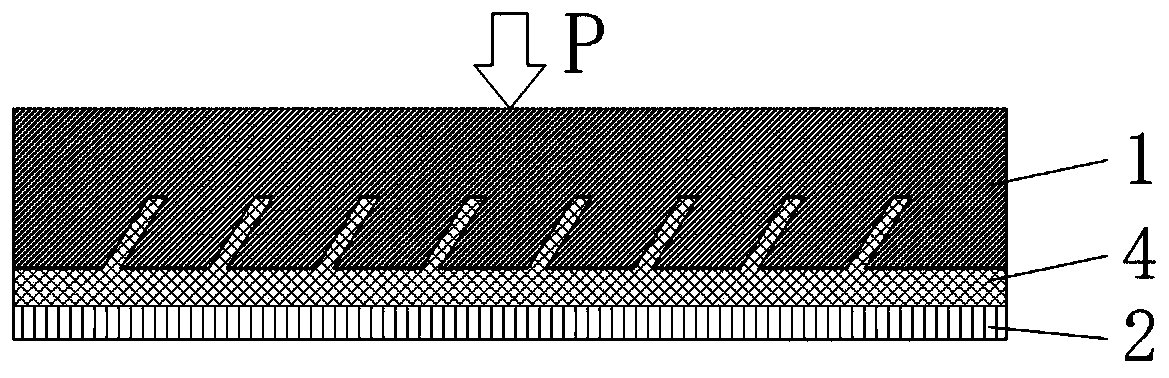

[0030] A manufacturing method of an electric double layer capacitive flexible pressure sensor enhanced by an inclined structure, comprising the following steps:

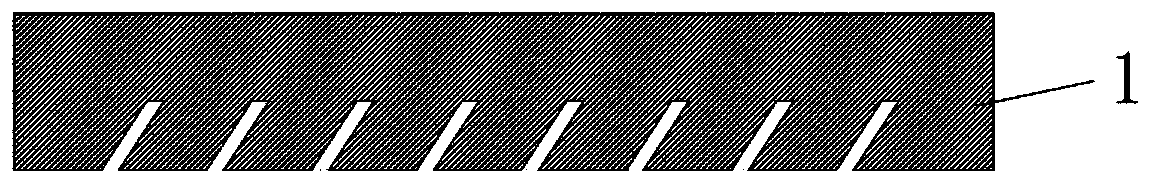

[0031] The first step, the preparation and processing of the imprint mold: refer to figure 1 , the imprinting mold 1 is prepared by the process of photolithography and mold turning, photolithography on the photoresist and development to obtain a tilted sheet-like array concave mold structure, and then polydimethylsiloxane (PDMS) and curing agent are used. After mixing at a mass ratio of 10:1, the mold was turned over to obtain a punch, and the punch was treated with low surface energy, that is, the mould was soaked in a fluorosilane solution for 6 hours, and then baked at 170 °C for 12 hours. Imprinting mold 1, the inclination angle is 20-40°;

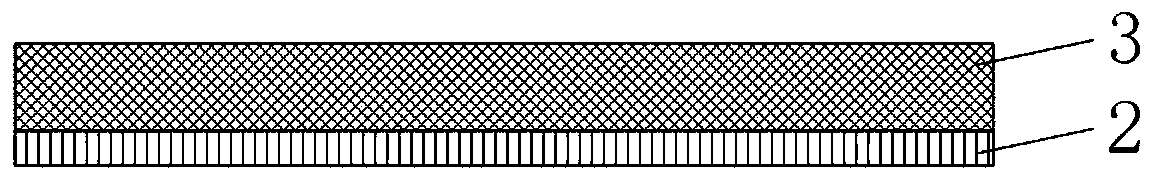

[0032] The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com