Low-sugar probiotic composition as well as preparation method and application thereof

A composition and probiotic technology, applied in the direction of food science, etc., can solve problems such as flatulence and neglect, and achieve the effect of reducing the possibility of flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also discloses a method for preparing the above-mentioned low-sugar probiotic composition, which includes the following steps:

[0029] Step 1. Dissolve steviol glycosides in formic acid solution, stir the reaction, concentrate to remove the reaction solvent, wash the obtained precipitate with ultrapure water, filter with suction, concentrate the filtrate again, dissolve it with ultrapure water, keep the supernatant, and prepare the obtained The solution is separated by a diatom-activated carbon chromatography column, followed by gradient elution with ultrapure water and ethanol solution to obtain a separated and purified sophorose solution.

[0030] Step 2. Spray-dry or freeze-dry the above-mentioned separated and purified sophorose solution to obtain sophorose powder.

[0031] Step 3: uniformly mix the prepared sophorose powder with xylitol, L-arabinose and dietary fiber, and ultrafinely pulverize to obtain the composition.

[0032] The inventio...

Embodiment 1

[0037] The first preparation method of the present invention for preparing a low-sugar probiotic composition comprises the following steps:

[0038] 11. Preparation of sophorose solution

[0039] Dissolve 10g steviol glycoside (98%) in 20~80mL formic acid solution, stir and react at 80°C for 30~40min, remove the reaction solvent by vacuum rotary evaporation, wash the obtained precipitate with 100mL ultrapure water, suction filter, discard the precipitate, Rotate again to obtain a second spin-evaporation solution, dissolve it in 100ml ultrapure water, and keep the supernatant. The obtained solution is separated by a diatom-activated carbon chromatography column, followed by gradient elution with ultrapure water and 5-30% ethanol solution to obtain a separated and purified sophorose solution.

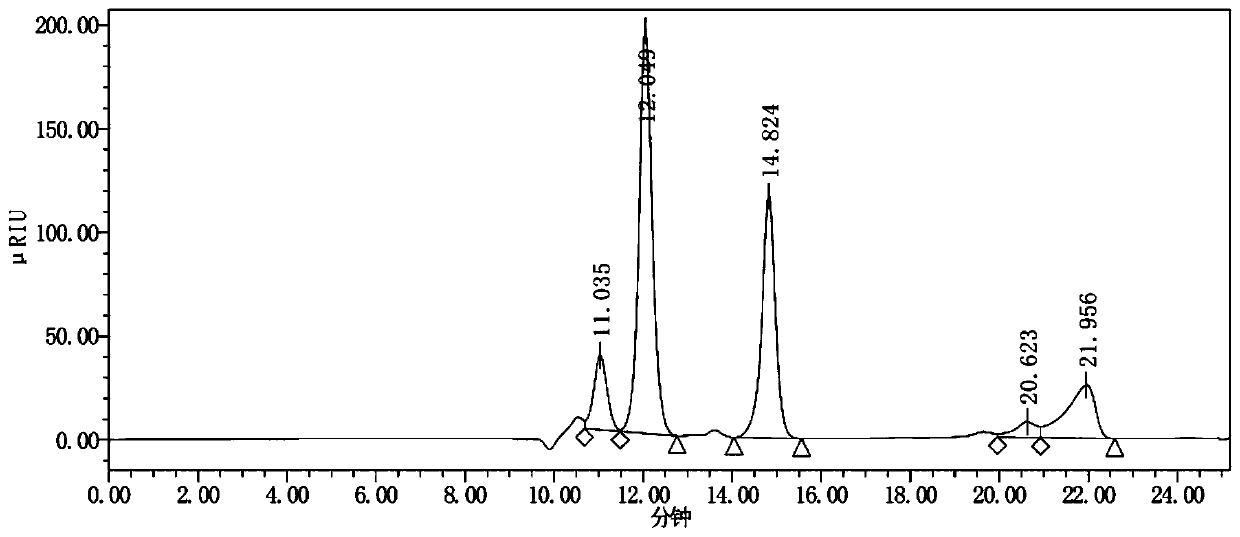

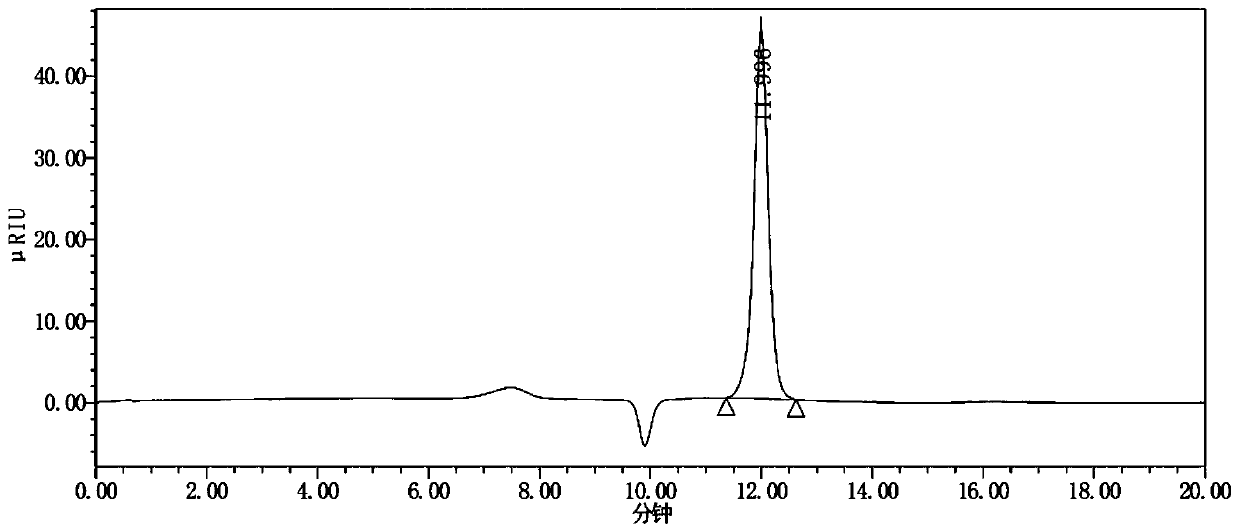

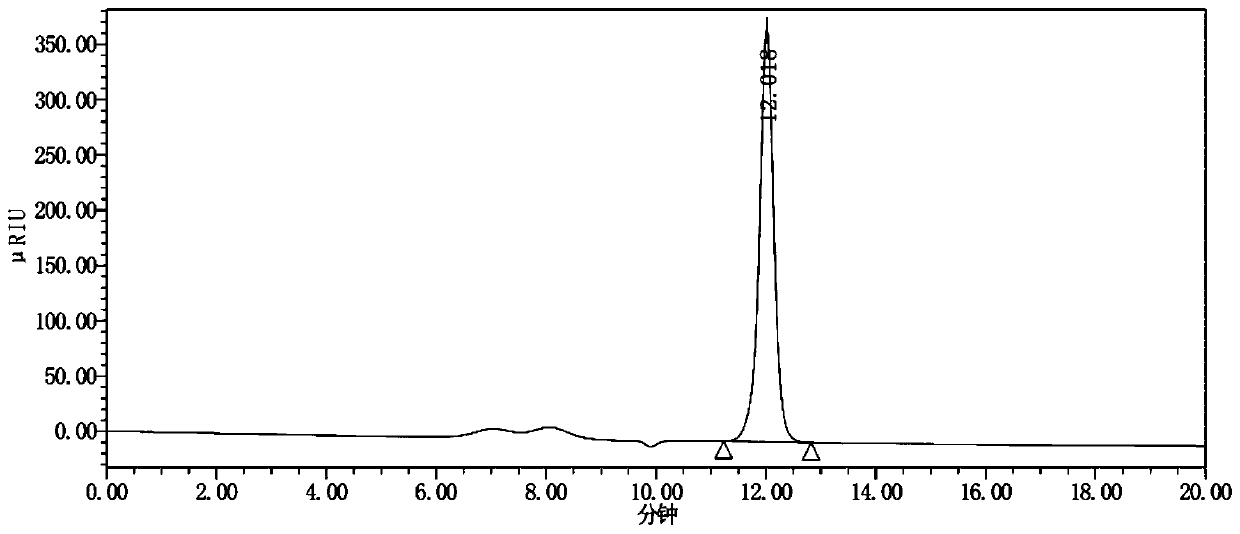

[0040] Compared figure 1 , figure 2 and image 3 The chromatogram shows that the concentration of sophorose in the reaction solution obtained by preparing sophorose by this method is...

Embodiment 2

[0061] The second preparation method of the present invention for preparing a low-sugar probiotic composition comprises the following steps:

[0062] Step 21, preparation of sophorose solution, and step 22, preparation of sophorose are the same as step 11 and step 12 of Example 1 respectively, and will not be repeated here.

[0063] 23. Preparation of probiotic composition

[0064] The sophorose solution separated and purified above is subjected to centrifugal spray drying to obtain the sophorose powder. The drying conditions are set at an inlet temperature of 160-180°C and an outlet temperature of 60-80°C, and the yield of sophorose reaches 30%-40%.

[0065] Each component was weighed according to the following formula: 35% sophorose, 20% xylitol, 20% L-arabinose and 25% dietary fiber, mixed evenly, and ultrafinely pulverized to obtain the composition.

[0066] The low-sugar composition prepared in this embodiment was subjected to the same evaluation experiment as in Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com