Pd/mesoporous Al2O3 catalyst capable of precisely regulating number of penta-coordinated Al<3+> in Al2O3 and preparation method and application of Pd/mesoporous Al2O3 catalyst

A catalyst and precise technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydrogenation hydrocarbon production, etc., can solve the problem of deactivation of active components, to prevent aggregation, high acetylene Conversion rate and effect of improving atomic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

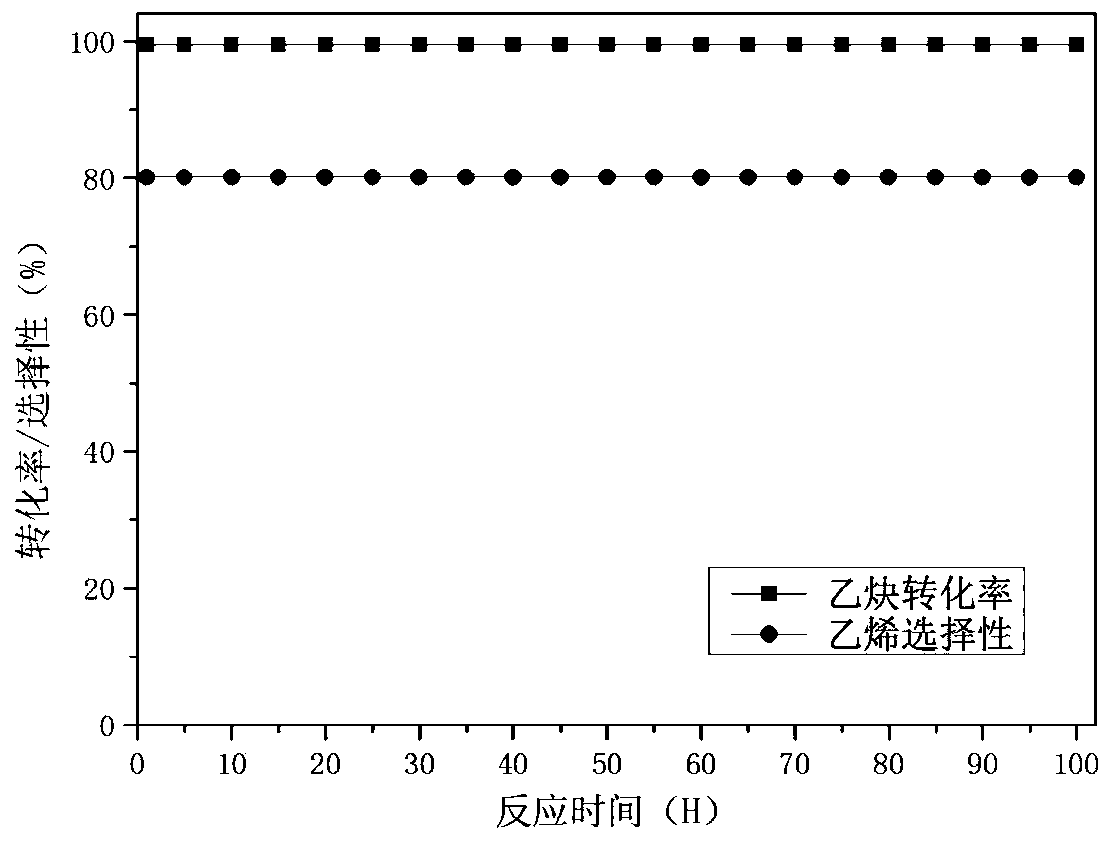

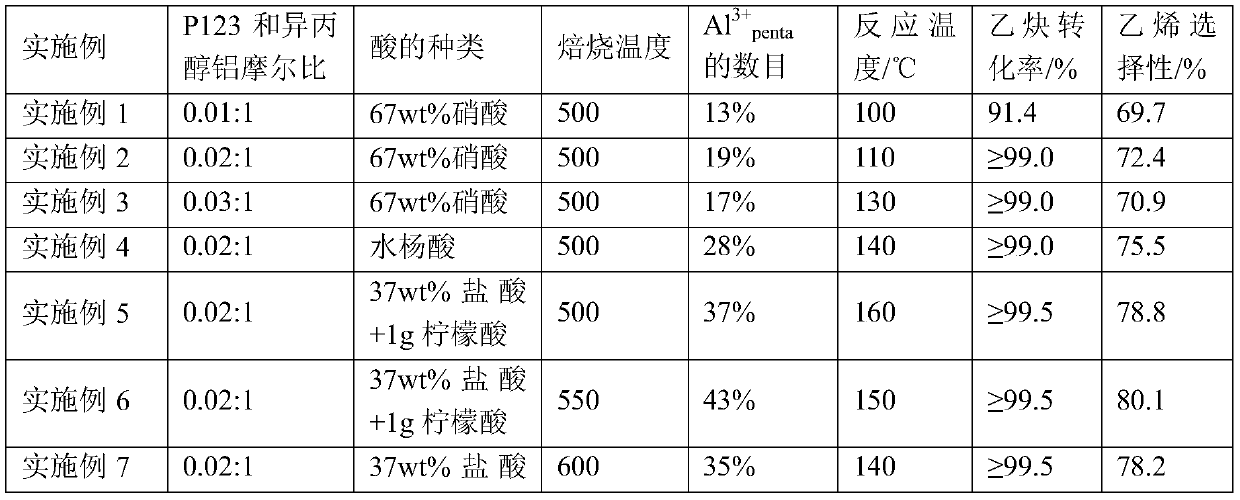

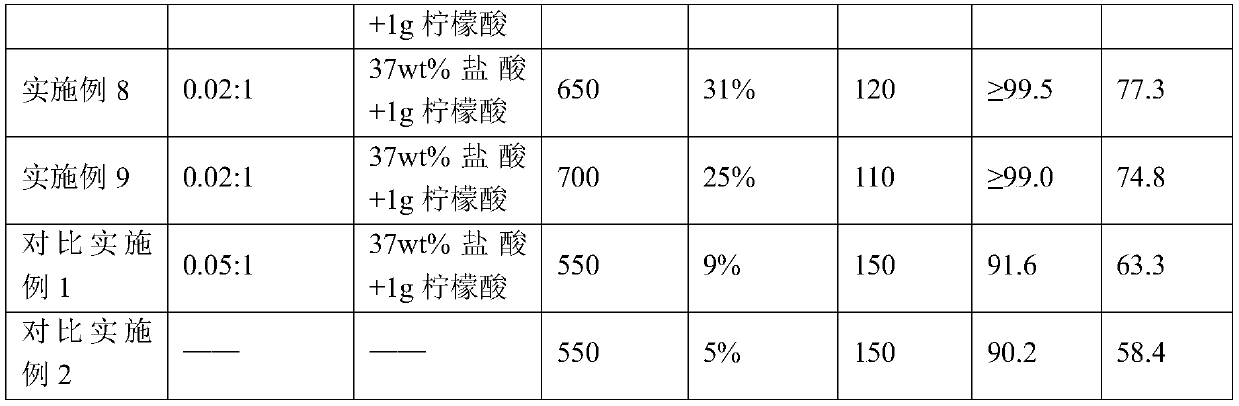

[0032] According to the material ratio in Table 1, weigh a certain amount of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, Mr=5800) into the beaker and slowly drop 40mL without After water ethanol, stir to fully dissolve P123. Add 3.2mL 67wt% nitric acid and 4g aluminum isopropoxide (ISO-AL), seal with polyethylene film, and continue stirring until completely dissolved. The solution was transferred to a petri dish, covered with a perforated polyethylene film, and dried in an oven at 60°C for 48 hours to volatilize the absolute ethanol solvent to obtain a sponge-like sample. Transfer the sample to a porcelain crucible and put it in a muffle furnace for 2h at 400°C and 5h at 800°C to obtain mesoporous Al 2 O 3 . The mesoporous Al 2 O 3 Pour palladium into the immersion solution with a mass concentration of 0.001g / mL, immerse it at room temperature for 12h, and dry it at 110°C for 12h. After cooling, it is placed in a muffle furnace and fired...

Embodiment 4

[0034] Weigh 2.2 g of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, Mr=5800) into a beaker and slowly drop 40 mL of absolute ethanol, and stir to fully dissolve P123 . Add 3.2mL of 37wt% hydrochloric acid, 1g of salicylic acid and 4g of aluminum isopropoxide (ISO-AL), seal with polyethylene film, and continue to stir until completely dissolved. The solution was transferred to a petri dish, covered with a perforated polyethylene film, and dried in an oven at 60°C for 48 hours to volatilize the absolute ethanol solvent to obtain a white flake sample. Transfer the sample to a porcelain crucible and put it in a muffle furnace for 2h at 400°C and 5h at 800°C to obtain mesoporous Al 2 O 3 . The mesoporous Al 2 O 3 Pour palladium into the immersion solution with a mass concentration of 0.001g / mL, immerse it at room temperature for 12 hours, and dry it at 110°C for 12 hours. After cooling, it is placed in a muffle furnace and calcined at 500°C for...

Embodiment 5

[0036] Weigh 2.2 g of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, Mr=5800) into a beaker and slowly drop 40 mL of absolute ethanol, and stir to fully dissolve P123 . Add 3.2mL of 37wt% hydrochloric acid, 1g of citric acid and 4g of aluminum isopropoxide (ISO-AL), seal with polyethylene film, and continue to stir until completely dissolved. The solution was transferred to a petri dish, covered with a polyethylene film with holes, and dried in an oven at 60°C for 48 hours to volatilize the absolute ethanol solvent to obtain a white flake sample. Transfer the sample to a porcelain crucible and put it in a muffle furnace for 2h at 400°C and 5h at 800°C to obtain mesoporous Al 2 O 3 . The obtained mesoporous Al 2 O 3 Pour palladium into the immersion solution with a mass concentration of 0.001g / mL, immerse it at room temperature for 12h, and dry it at 110°C for 12h. After cooling, it is placed in a muffle furnace and fired at 500°C for 4h to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com