Complex wood bundle, complex recombinant wood and preparation method thereof

A technology for reconstituting wood and wood bundles, applied in wood treatment, flat products, impregnated wood, etc., can solve problems such as cracking, deformation, and easy occurrence of wire skipping, and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

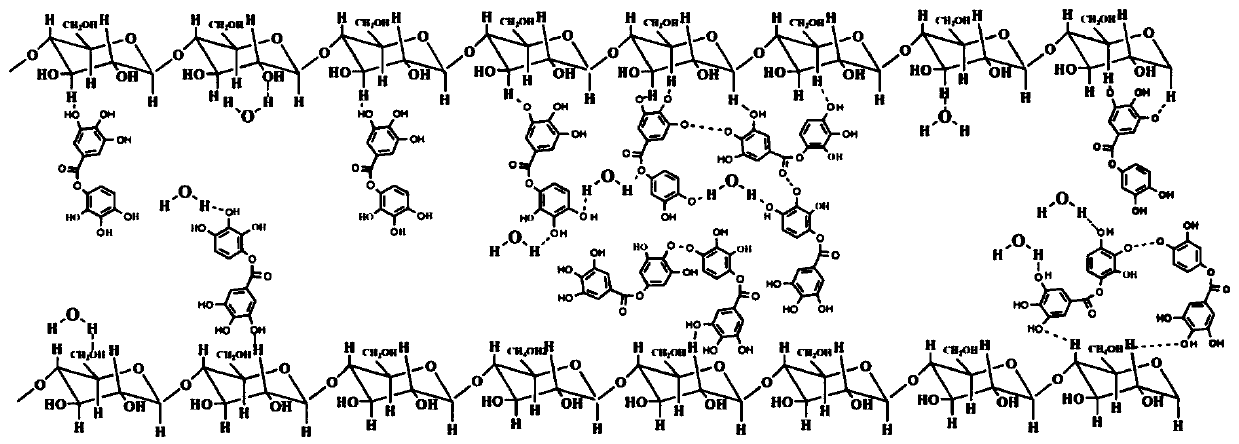

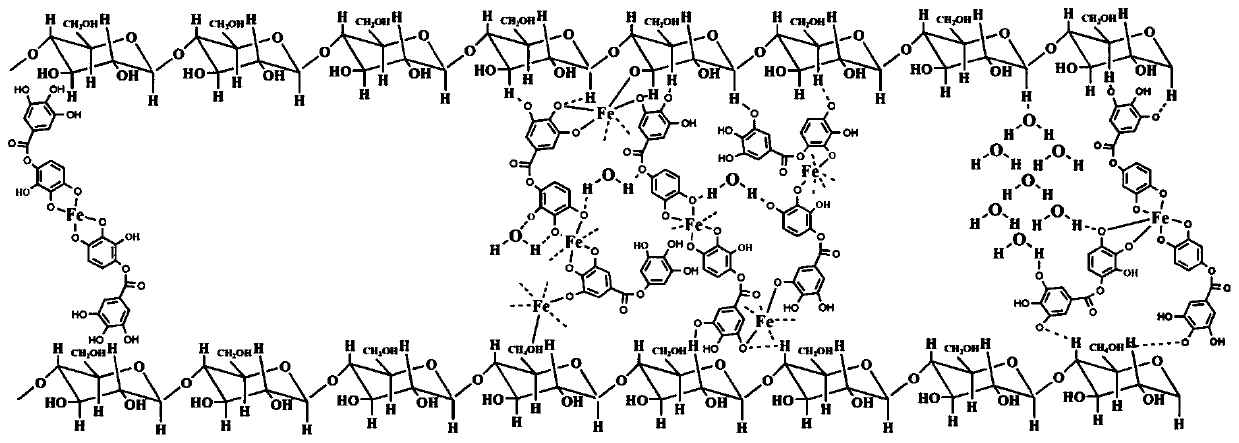

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of complexed wood beams, comprising:

[0058] Step 1: Prepare an appropriate amount of wooden beams;

[0059] 11) the eucalyptus saw is cut into the wood section of 2000mm length;

[0060] 12) above-mentioned wooden segment is rotary-cut into the veneer of 8mm thickness;

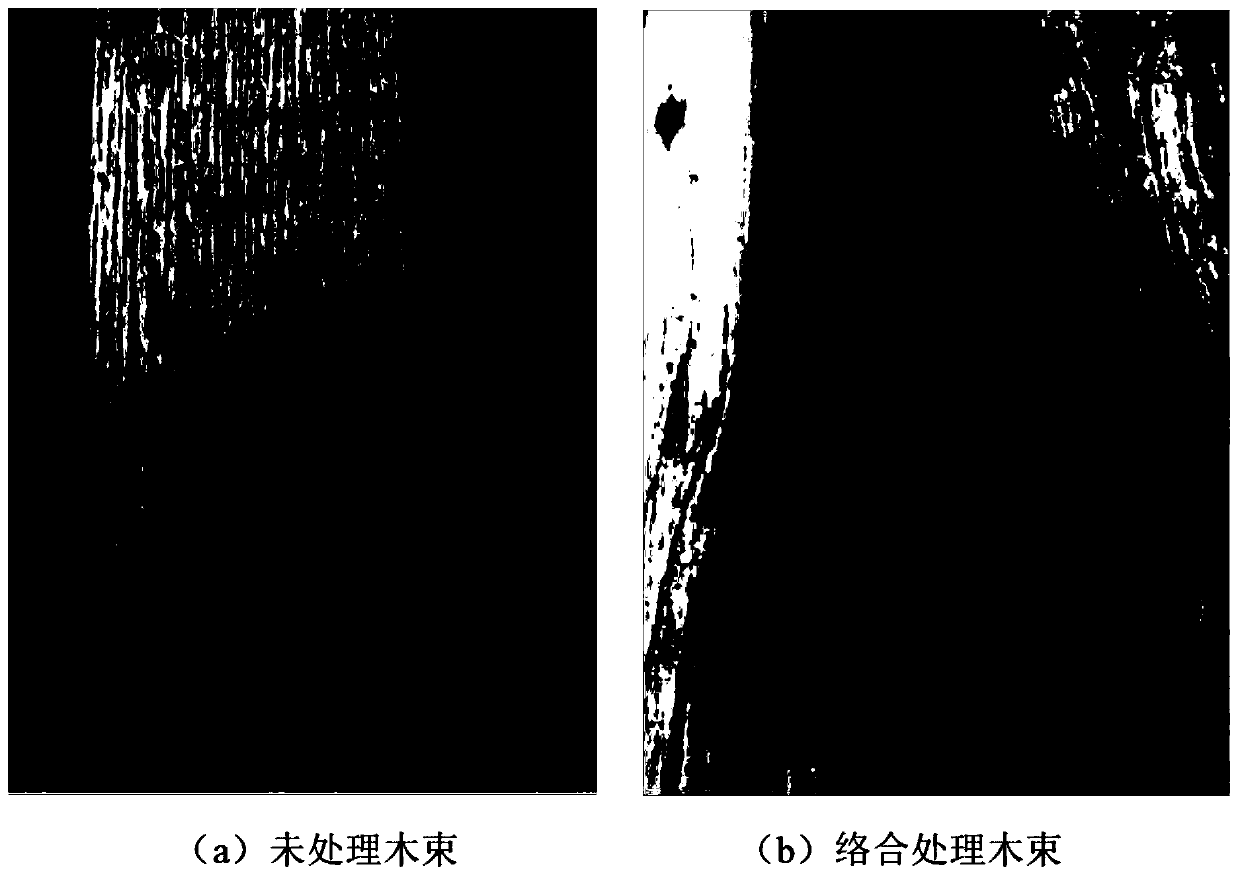

[0061] 13) The above-mentioned veneers are disentangled to form wood bundles, the average diameter of the wood bundles is 1.3mm, and the maximum diameter is less than 5.0mm, and the wood bundle conduits, the cell walls of parenchyma cells or the intercellular layer of fibers are arranged A series of irregular cracks, see image 3 (a);

[0062] 14) drying the above-mentioned wood bundles to a moisture content of 6%;

[0063] Step 2: introduce plant polyphenols into wood beams to obtain polyphenol wood beams;

[0064] 21) Dissolving tannin in water and stirring evenly to form an aqueous tannin solution with a concentration of 1.0 g / L;

[0065] 22) Pressurize and impregnate the...

Embodiment 2

[0073] A preparation method of complexed recombined wood, using the complexed wood bundle prepared in embodiment 1 as raw material, comprising:

[0074] Step 1: Sizing

[0075] The urea-formaldehyde resin with a molecular weight of 600 is coated on the surface of the complex wood beam by roller coating, and the sizing amount is 8%;

[0076] Step 2: Dry

[0077] Dry the impregnated composite wood bundles in a drying kiln at a drying temperature of 60°C and control the drying moisture content at 14%

[0078] Step 3: Assembly

[0079] The dried complexed wood bundles are assembled along the grain to form complexed recombined wood slabs;

[0080] Step 4: Gluing and Molding

[0081] Put the above-mentioned recombined wood slabs into the cold press, and make complex recombined wood squares by cold pressing, the pressure is 60MPa, and the cold pressing temperature is normal temperature; it is sent into the curing tunnel for curing, the curing temperature is 135 °C, and the curing...

Embodiment 3

[0087] A preparation method of complexed wood beams, comprising:

[0088] Step 1: Prepare an appropriate amount of wooden beams;

[0089] 11) Poplar sawn is cut into the wood section of 2000mm length;

[0090] 12) peeling the above-mentioned wood section into a veneer with a thickness of 6mm;

[0091] 13) The above-mentioned veneer is decomposed to form a wood bundle, the average diameter of the single wood fiber bundle is 1.3mm, and the maximum diameter is less than 5.0mm, and the wood bundle vessel, the cell wall of the parenchyma cell or the intercellular layer of the fiber A series of irregular cracks are set in

[0092] 14) drying the above-mentioned wood bundles to a moisture content of 30%;

[0093] Step 2: introduce plant polyphenols into wood beams to obtain polyphenol wood beams;

[0094] 21) Dissolving myrica rubra extract in water and stirring evenly to form a plant polyphenol aqueous solution with a concentration of 2.5g / L;

[0095] 22) Implant the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap