Method for synthesizing ketoxime

A technology for synthesizing ketoxime and materials, applied in oxime preparation, organic chemistry, etc., can solve the problems of gas-liquid-solid heterogeneous mass transfer and heat transfer, many side reactions in a series, poor product selectivity, etc., to avoid pollution and separation problems, improved reaction efficiency, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

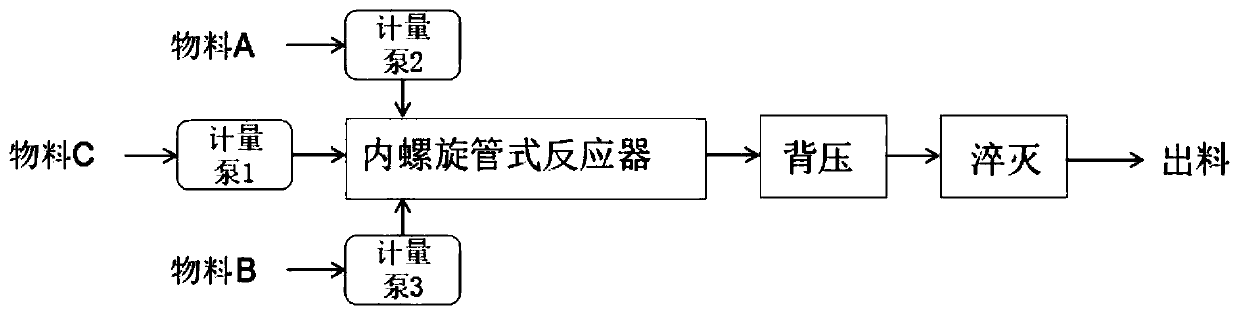

Method used

Image

Examples

Embodiment 1

[0023] First, raise the temperature of the temperature control system to 50°C, then feed material A butanone and catalyst, material B ammonia, and material C hydrogen peroxide into the tubular reactor. The feed is 1% of the amount of ketone, the feed rate of ammonia and hydrogen peroxide is controlled by pH 9, the pressure of the back pressure valve is adjusted to 0.1MPa, the residence time of the feed is 2min, after the feed is stable for 30min, the reaction is quenched by sampling, and the organic phase is analyzed and water content. Based on 100 g of ketone feed, the weight of the organic phase is 125.3 g, the conversion of ketone is 98.57%, and the selectivity is 99.9%.

Embodiment 2

[0025] First, raise the temperature of the temperature control system to 80°C, then feed three strands of material A, acetone and catalyst, material B ammonia, and material C hydrogen peroxide into the tubular reactor. 10% of the amount of ketone, the feed rate of ammonia and hydrogen peroxide is controlled by pH 10, the pressure of the back pressure valve is adjusted to 0.6MPa, the residence time of the material is 15min, after the feed is stable for 30min, the reaction is quenched by sampling, and the organic phase and Aqueous phase product content. Based on 100 g of ketone feed, the weight of the organic phase is 127.8 g, the conversion of ketone is 96.91%, and the selectivity is 99.7%.

Embodiment 3

[0027] First, raise the temperature of the temperature control system to 70°C, then feed three strands of material A butanone and catalyst, material B ammonia, and material C hydrogen peroxide into the tubular reactor. The feed is 10% of the amount of ketone, the feed rate of ammonia and hydrogen peroxide is controlled by pH 12, the pressure of the back pressure valve is adjusted to 0.1MPa, the residence time of the feed is 10min, after the feed is stable for 30min, the reaction is quenched by sampling, and the organic phase is analyzed and aqueous product content. Based on 100 g of ketone feed, the weight of the organic phase is 126.4 g, the conversion of ketone is 99%, and the selectivity is 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com