Nano AlN particle reinforced mixed crystal heat-resistant aluminum-based composite material and preparation method

A technology of particle reinforcement and composite materials, applied in the field of composite materials, can solve the problems of low plasticity of materials, and achieve the effects of high comprehensive mechanical properties, good wettability, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

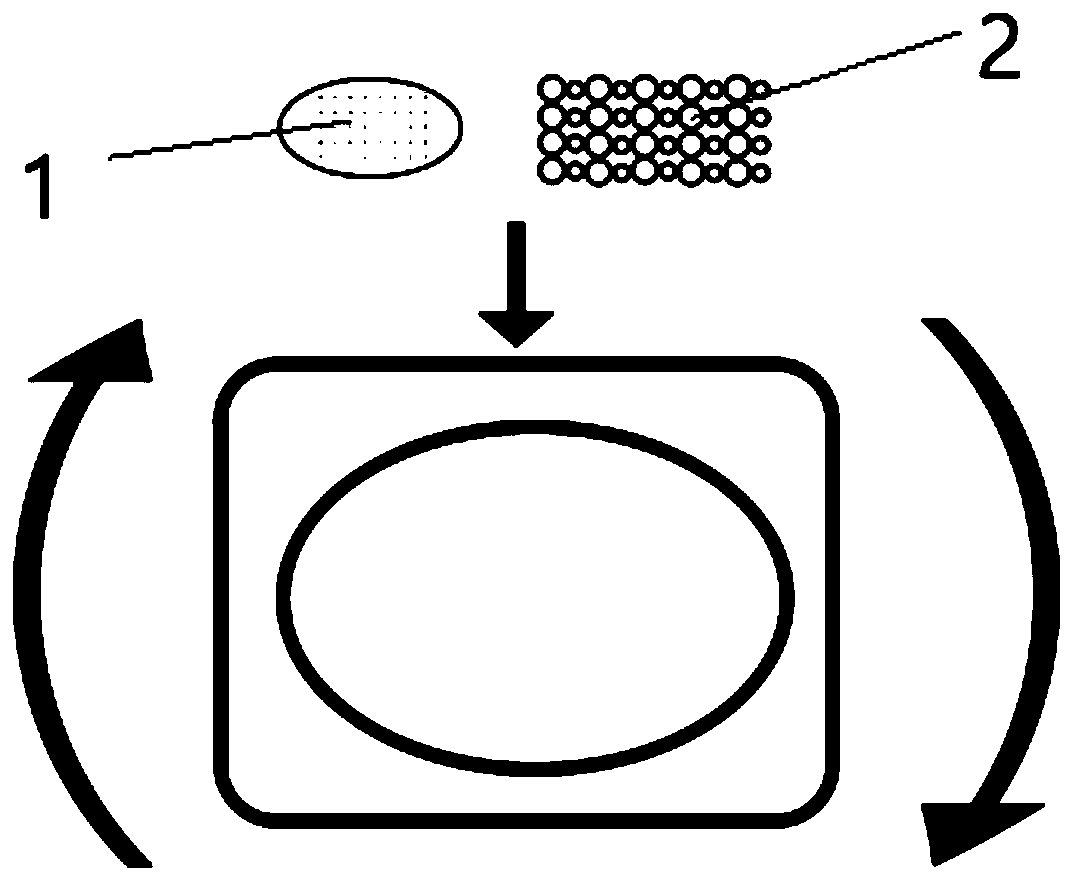

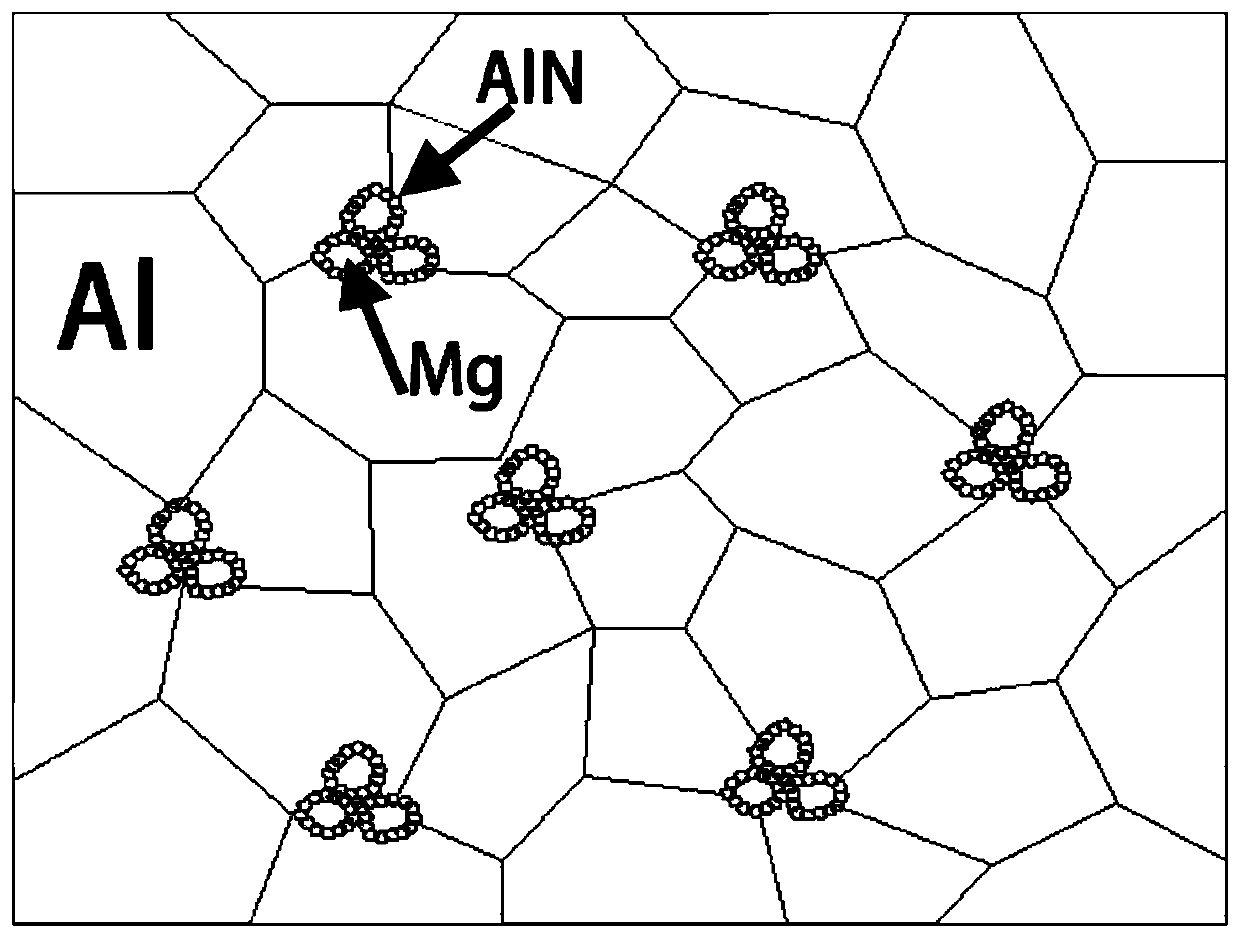

[0031] The invention provides an AlN particle-reinforced aluminum-based mixed crystal composite material with excellent comprehensive performance, and proposes a preparation method with simple process and suitable for industrial production. The present invention uses industrial pure aluminum powder and magnesium nitride powder as raw materials, and adopts the method of low-temperature sintering, heat treatment and deformation to prepare a high-strength, high-toughness, heat-resistant AlN-reinforced aluminum-based mixed crystal composite material. The boundaries and grains contain a large number of in-situ self-generated AlN reinforced particles. At the same time, the magnesium element is solid-dissolved in the matrix around the AlN-reinforced particles. The elements are fine grained, and the AlN-enhanced grain-poor zone is mainly coarse grained. The mass percentage of AlN in the composite material is 0.80-12.30, and the size is 10nm-300nm; the mass percentage of Mg element is ...

Embodiment 1

[0040] Step 1, pretreatment: Prepare the required raw materials according to the following mass percentages: 97.15% of aluminum powder with a particle size of ≤50μm, 2.50% of magnesium nitride powder with a particle size of ≤2μm, and 0.35% of activated carbon with a particle size of ≤3μm, wherein activated carbon is the active agent; the prepared Aluminum powder, magnesium nitride powder and activated carbon are mixed and then degassed and wrapped.

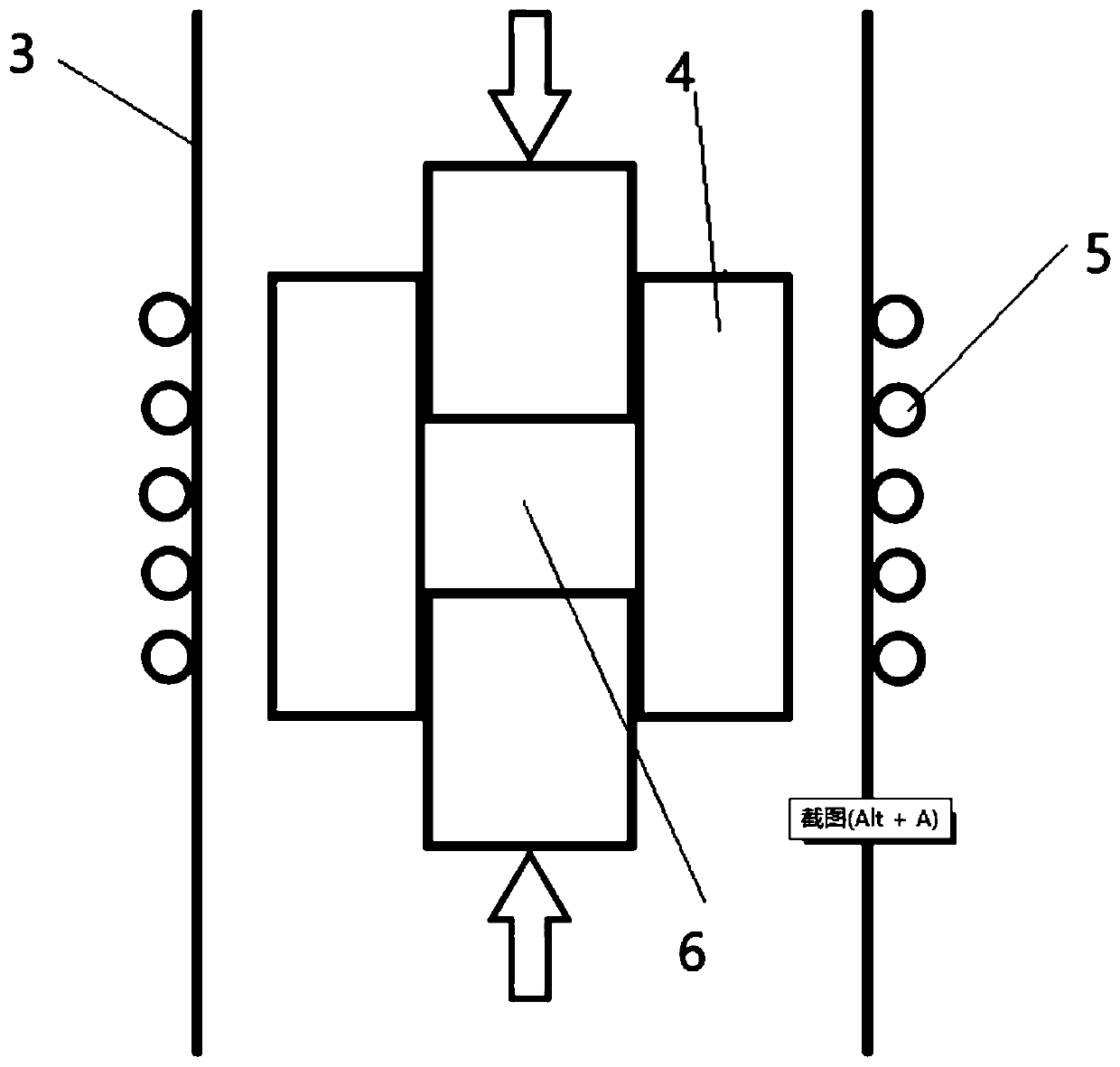

[0041] Step 2, sintering treatment: under the protective atmosphere of oxygen barrier and argon gas, hot isostatic pressing sintering is carried out on the degassed raw materials; the pressure condition is 100MPa, the sintering temperature is 620°C, and the sintering time is 6h;

[0042] Step 3, solution treatment: place the sintered block in a heat treatment furnace for solution treatment; the solution temperature is 300°C, the solution time is 2 hours, and the solution medium is water;

[0043] Step 4, forming treatment: put the...

Embodiment 2

[0045] Step 1, pretreatment: Prepare the required raw materials according to the following mass percentages: 89.50 of aluminum powder with a particle size of ≤50 μm, 10.00 of magnesium nitride powder with a particle size of ≤2 μm, and 0.50 of activated carbon with a particle size of ≤3 μm, wherein activated carbon is the active agent; the prepared Aluminum powder, magnesium nitride powder and activated carbon are mixed and then degassed and wrapped.

[0046] Step 2, sintering treatment: under the protective atmosphere of oxygen barrier and argon gas, hot isostatic pressing sintering is carried out on the degassed raw materials; the pressure condition is 150MPa, the sintering temperature is 550°C, and the sintering time is 10h;

[0047] Step 3, solution treatment: place the sintered block in a heat treatment furnace for solution treatment; the solution temperature is 330°C, the solution time is 3 hours, and the solution medium is water;

[0048] Step 4, forming treatment: put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com