Coating treatment method for breathable corrugated box

A treatment method and corrugated box technology, applied in paper coating, fiber raw material treatment, coating, etc., can solve the problems of increasing the cost of using cartons, not having durability of cartons, threatening the safety of pets, etc., to achieve heat isolation, good Stool absorption effect, stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

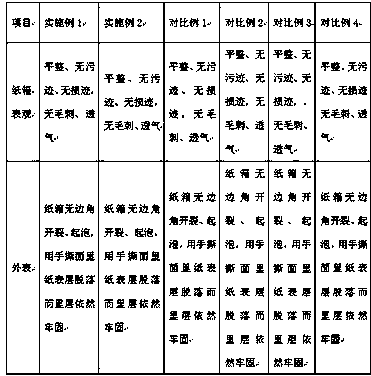

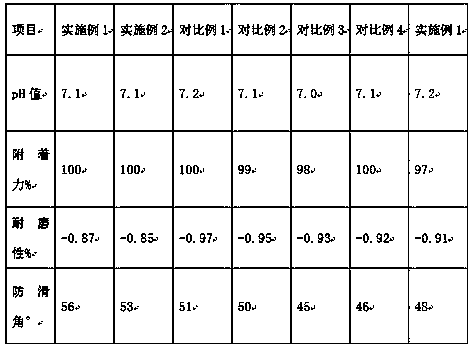

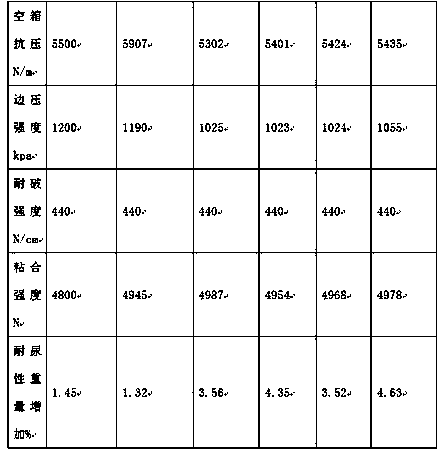

Examples

Embodiment 1

[0021] A coating treatment method for air-permeable corrugated boxes, specifically comprising the following steps:

[0022] (1) In parts by weight, 34 parts of cordierite powder and 24 parts of carbon black were mixed and pulverized to 320 mesh, baked in an oven with a temperature of 85°C for 50 minutes, and taken out to obtain the adsorption filler, which was kept warm for later use;

[0023] (2) Add 37 parts of butyl acrylate, 23 parts of ethyl acrylate, 23 parts of vinyl acetate and 4.0 parts of N-methylol acrylamide into the reaction kettle, and add 30 parts of bisphenol A type epoxy while stirring Resin and make it dissolve, then dropwise add aqueous solution containing 140 parts of water, 0.3 parts of potassium persulfate, 0.05 parts of sodium bisulfite, 1 part of polyvinyl alcohol alkyl phenyl ether emulsifier, emulsification is completed under high-speed stirring, and the above The mixture was added to the reaction kettle under nitrogen atmosphere, and the heat preserv...

Embodiment 2

[0032] A coating treatment method for air-permeable corrugated boxes, specifically comprising the following steps:

[0033] (1) In terms of parts by weight, mix and pulverize 27 parts of cordierite powder and 17 parts of carbon black to 300 mesh, bake in an oven with a temperature of 83°C for 46 minutes, take it out, and obtain the adsorption filler, keep it warm for later use;

[0034] (2) Add 34 parts of butyl acrylate, 15 parts of ethyl acrylate, 18 parts of vinyl acetate and 2.5 parts of N-methylol acrylamide into the reaction kettle, and add 30 parts of bisphenol A type epoxy while stirring Resin and make it dissolve, then dropwise add aqueous solution containing 120 parts of water, 0.1 part of potassium persulfate, 0.02 part of sodium bisulfite, 0.4 part of polyvinyl alcohol alkyl phenyl ether emulsifier, emulsification is completed under high-speed stirring, and the above The mixture was added into the reaction kettle under nitrogen atmosphere, and the heat preservation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com