Method of preparing three-dimensional atom probe sample on powder particle

A technology of atom probes and powder particles, which is applied in the field of material preparation, can solve the problems of inability to collect valid data, inability to determine the sampling position, weak combination of particles and the matrix, etc., and achieve the goal of reducing sample preparation procedures, accurate data, and reducing fractures effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

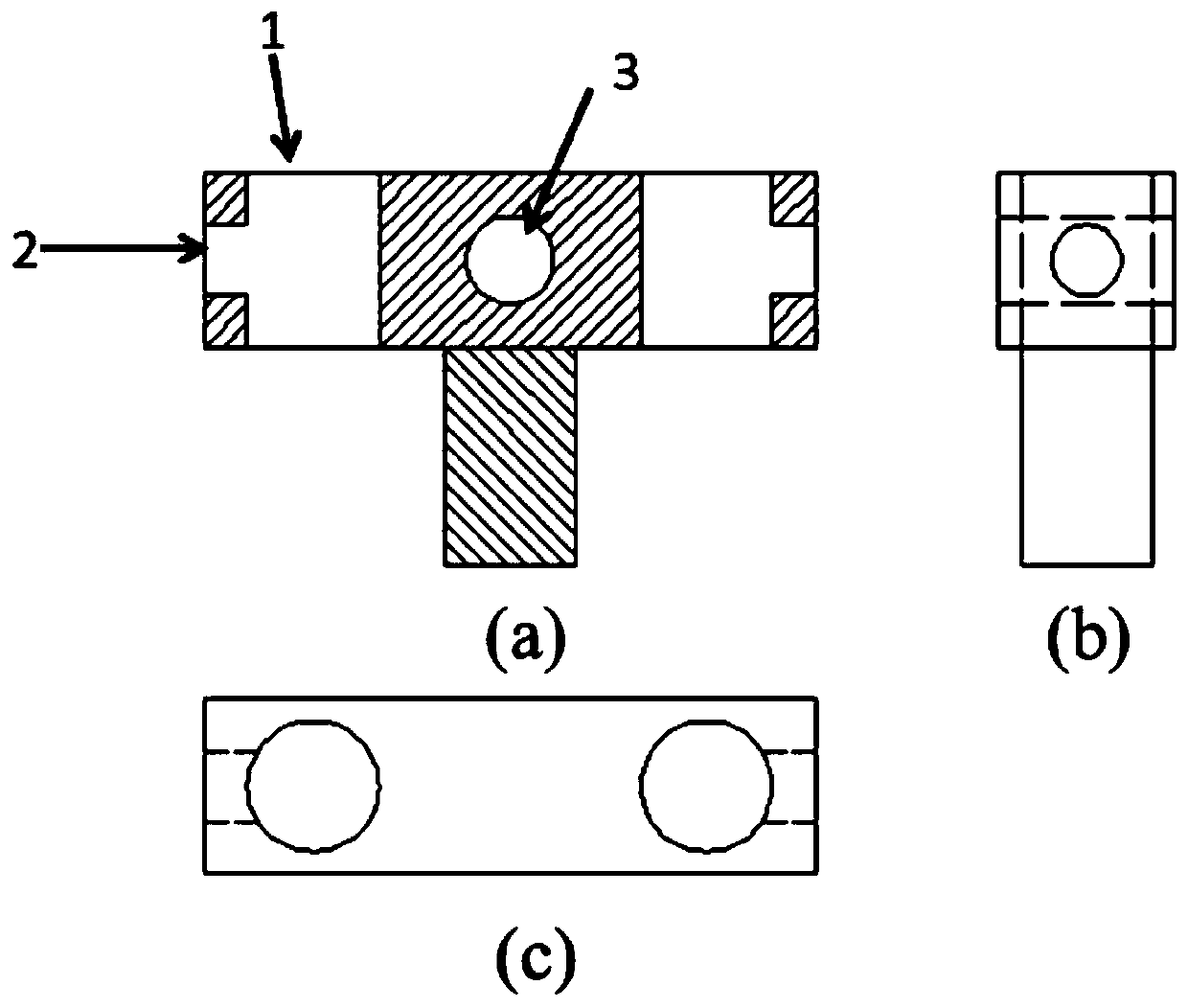

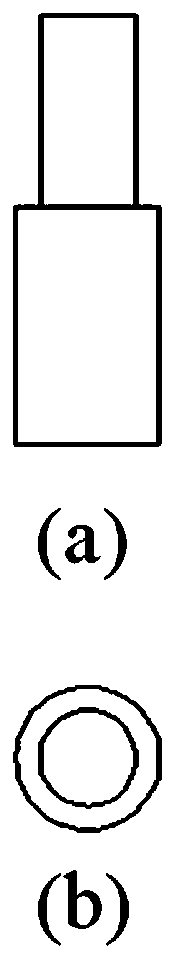

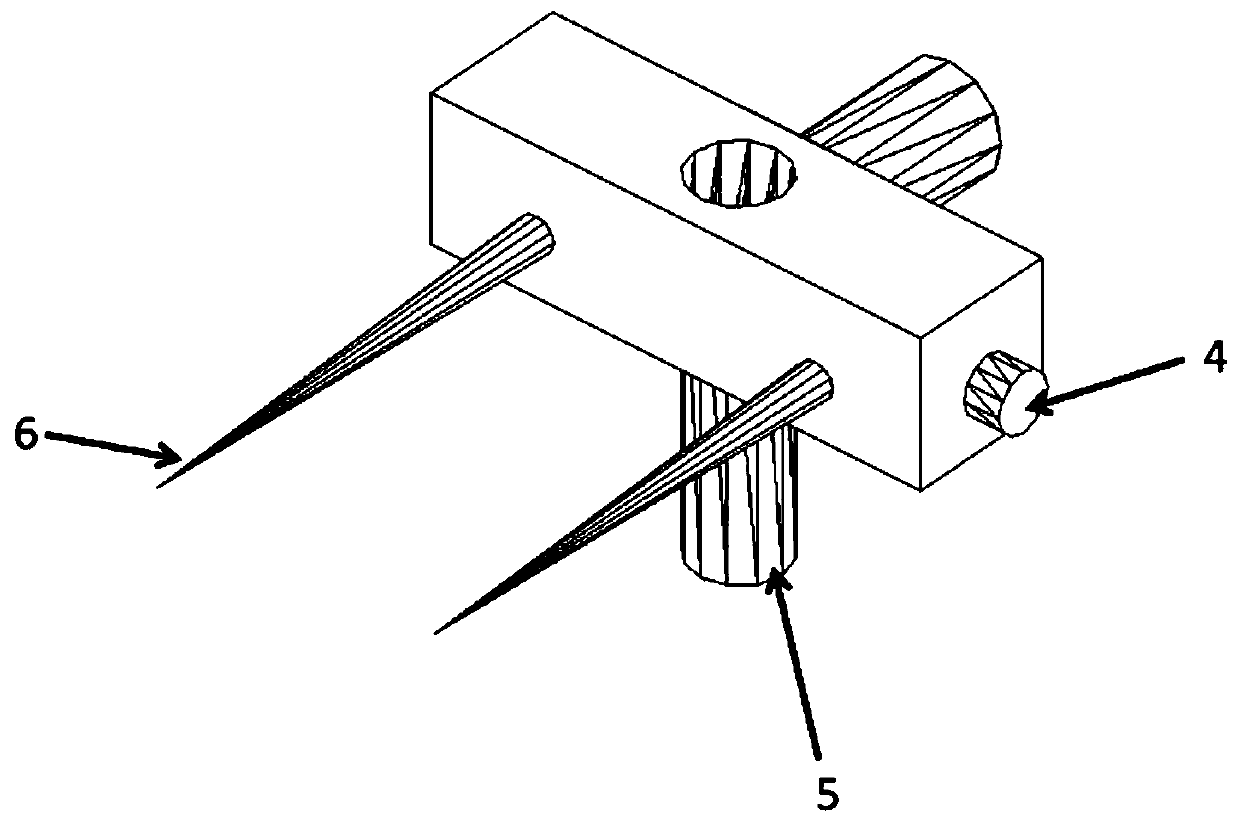

[0077] A method for preparing a three-dimensional atom probe sample on powder particles. The method adopts a FIB / SEM dual-beam system, wherein FIB is a Focused Ion Beam, which is a focused ion beam, and SEM is a Scanning Electron Microscope, which is a scanning electron microscope; The sample in this embodiment is TiC ceramic particle reinforced reinforcement particle TiC of Al-based composite material, and the method mainly includes the following steps:

[0078] S1: using hydrochloric acid to dissolve the Al matrix and extract the TiC particles;

[0079] S2: Repeatedly wash with water and alcohol, remove the extract, and transfer the particles into alcohol;

[0080] S3: Use an ultrasonic instrument to vibrate the alcohol to disperse the particles evenly;

[0081] S4: Use a dropper to drop the suspension containing particles onto the TEM support membrane grid, and then use a drying lamp to dry;

[0082] S5: Transfer the TEM support membrane carrier grid to the nail-shaped sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com