A mini LED light board, preparation method and display device

A technology of LED chips and light boards, applied in lighting devices, lighting device components, circuit layouts, etc., can solve problems such as solder joint breakage of MiniLED chips, reduce curing shrinkage, reduce curing stress, avoid displacement and The effect of solder joint fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present application also provides a method for preparing a Mini LED light panel, as shown in the attached Figure 5 As shown, the method includes:

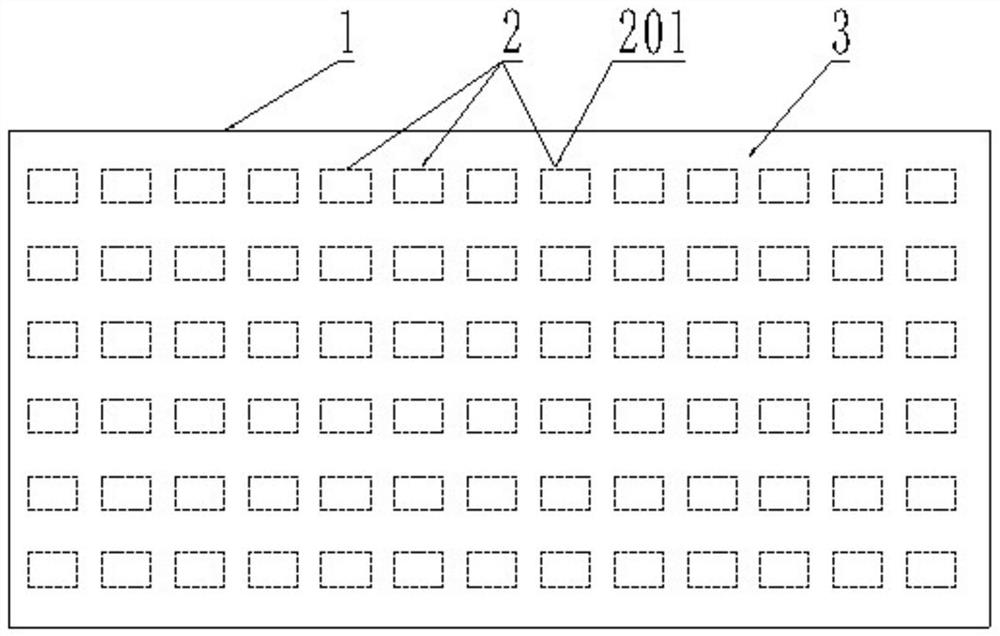

[0050] S101: Fixing the LED chip: fixing the LED chip to the circuit board to form a first LED chip board.

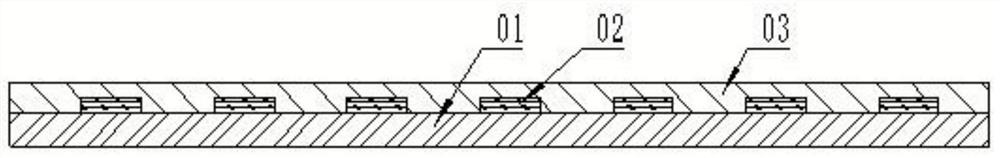

[0051] Obtain a circuit board, and fix the LED chip on the circuit board; usually, a chip fixing position is preset on the circuit board, such as setting a pad, and the LED chip is fixed according to the preset chip fixing position. Specifically, dispensing equipment is used to dispense silver paste point by point on the welding bracket of the circuit board, and a die bonding machine is used to transfer the LED chips to the welding bracket on the circuit board for fixed welding. Get the first LED chip board.

[0052] Among them, the LED chip can be obtained by cutting the LED wafer substrate by cutting technology. Usually, the LED chip on the substrate is cut by plasma, electron beam and other cutting technolog...

Embodiment 1

[0069] In a Mini LED light board, the composition ratio of the encapsulation layer is: bisphenol A epoxy resin 90g; nano-SiO 2 3g; silane coupling agent KH-570 0.1g; spirocyclic orthoester SOE expansion monomer 3g, curing agent chain flexible aromatic diamine 0.5g. The preparation of Mini LED light board is as follows:

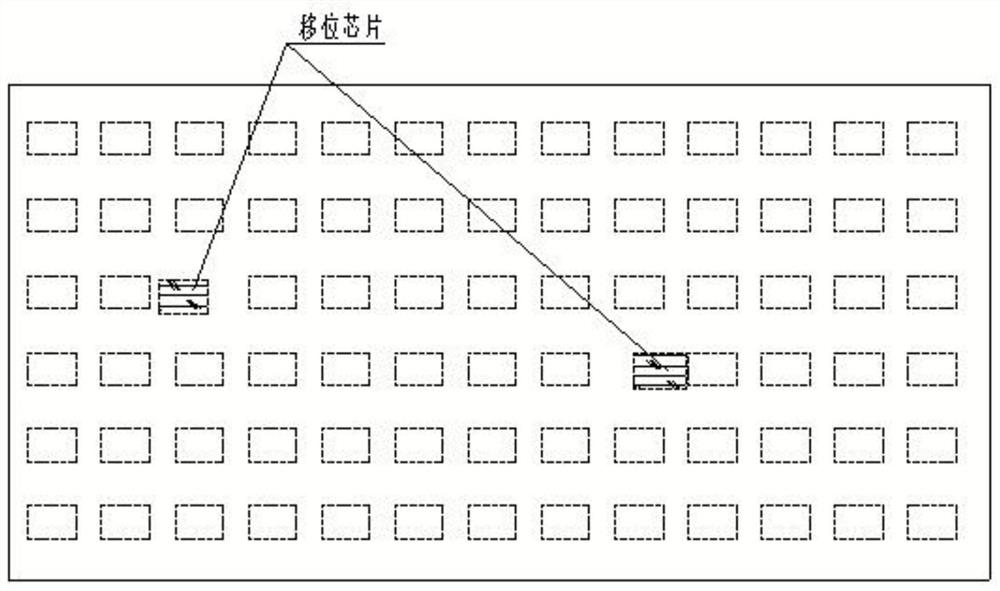

[0070] Mix the silane coupling agent KH-570 into absolute ethanol, add glacial acetic acid, and configure it into an alcohol solution of silane coupling agent KH-570 with a pH value of 4. 2 Add the silane coupling agent KH-570 alcohol solution with the pH value of 4, electromagnetic stirring, ultrasonic dispersion and centrifugal treatment, grinding and drying to obtain modified nano-SiO 2 . The modified nano-SiO 2 , Expanding monomer and curing agent are added into epoxy acrylate, mixed at high speed, and vacuum defoamed to obtain encapsulant. The LED chip is transferred to be fixed and soldered to the circuit board to form a first LED chip board. Throu...

Embodiment 2

[0072] In a Mini LED light board, the composition ratio of the encapsulation layer is: epoxy acrylate 105g; spirocyclic orthoester SOE expansion monomer 3g, curing agent trimethylolpropane triacrylate 0.5g. The preparation of Mini LED light board is as follows:

[0073] The expansion monomer and the curing agent are added into the epoxy acrylate, mixed at a high speed, and defoamed in a vacuum to obtain an encapsulant. The LED chip is transferred to be fixed and soldered to the circuit board to form a first LED chip board. Through the glue filling equipment, the encapsulant is coated on the first LED chip board to encapsulate the LED chip to form a package layer with a thickness of 1.3mm, and the lamp board is cured under UV irradiation. The curing time is 10min, and the Mini LED lamp is completed. board packaging. Check the packaged Mini LED light board, the Mini LED chip on it has no displacement, and the lighting display is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com