A kind of preparation method of isotropic ceramic nanowire preform

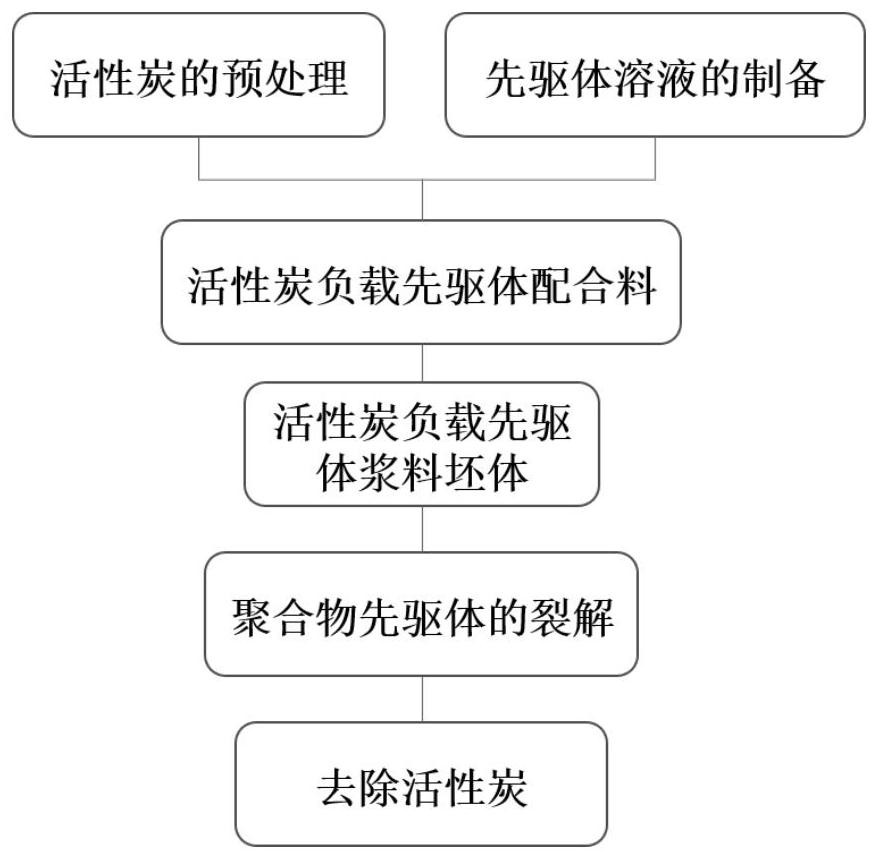

An isotropic and prefabricated technology, which is applied in the field of preparation of isotropic ceramic nanowire prefabricated bodies, can solve the problems of low yield and uneven distribution of nanophases, and achieve simple preparation steps, uniform structure and controllable size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1. Pretreatment of activated carbon: the present invention uses activated carbon powder as a template. Soak the activated carbon powder in acetone for 24 hours, then soak it in distilled water at 90°C for 30 minutes to remove impurities in the activated carbon powder. The activated carbon powder was then dried in a vacuum oven at a drying temperature of 100°C and a drying time of 12 hours;

[0040] Step 2. Preparation of the precursor solution: the polycarbosilane precursor and xylene were prepared into a precursor solution at a mass ratio of 1:5, and the magnetic stirring was used to continuously stir for 30 minutes at a speed of 200 rpm. Then, the catalyst nickelocene was mixed in a ratio of 5wt.%, and then magnetic stirring was used to continuously stir for 30min at a speed of 200r / min;

[0041] Step 3. Preparation of activated carbon-loaded precursor batch: Take an appropriate amount of activated carbon powder after impurity removal and mix it with the precurs...

Embodiment 2

[0047] Step 1. Pretreatment of activated carbon: the present invention uses activated carbon powder as a template. Soak the activated carbon powder in acetone for 24 hours, then soak it in distilled water at 90°C for 30 minutes to remove impurities in the activated carbon powder. The activated carbon powder was then dried in a vacuum oven at a drying temperature of 100°C and a drying time of 12 hours;

[0048] Step 2. Preparation of the precursor solution: the polysilazane precursor and cyclohexane were prepared at a mass ratio of 1:5 to prepare a precursor solution, and the magnetic stirring was used to continuously stir at 200 rpm for 30 min. Then the catalyst ferrocene was mixed in a ratio of 5wt.%, followed by magnetic stirring at a speed of 200r / min for 30min;

[0049] Step 3. Preparation of activated carbon-loaded precursor batch: Take an appropriate amount of activated carbon powder after impurity removal and mix it with the precursor solution prepared in step 2 to mak...

Embodiment 3

[0055] Step 1. Pretreatment of activated carbon: the present invention uses activated carbon powder as a template. After soaking the activated carbon powder in acetone for 24 hours, soak it in distilled water at 70°C for 1 hour to remove impurities in the activated carbon powder. The activated carbon powder was then dried in a vacuum oven at a drying temperature of 100°C and a drying time of 24 hours;

[0056] Step 2. Preparation of the precursor solution: the polycarbosilane precursor and cyclohexane were prepared into a precursor solution at a mass ratio of 1:10, and the magnetic stirring was continuously stirred at 200 rpm for 30 min. Then the catalyst ferrocene was mixed in a ratio of 5wt.%, followed by magnetic stirring at a speed of 200r / min for 30min;

[0057] Step 3. Preparation of activated carbon-loaded precursor batch: Take an appropriate amount of activated carbon powder after impurity removal and mix it with the precursor solution prepared in step 2 to make an ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com