POD simulant and process for applying the POD simulant to fertilizer

A simulant, fertilizer technology, applied in the application, ammonium salt fertilizer, fertilizer mixture and other directions, can solve the problems of unbalanced fertilizer nutrition, weak fertilizer nutrition and other problems, and achieve the effect of increasing fertility, rich in nutrients and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

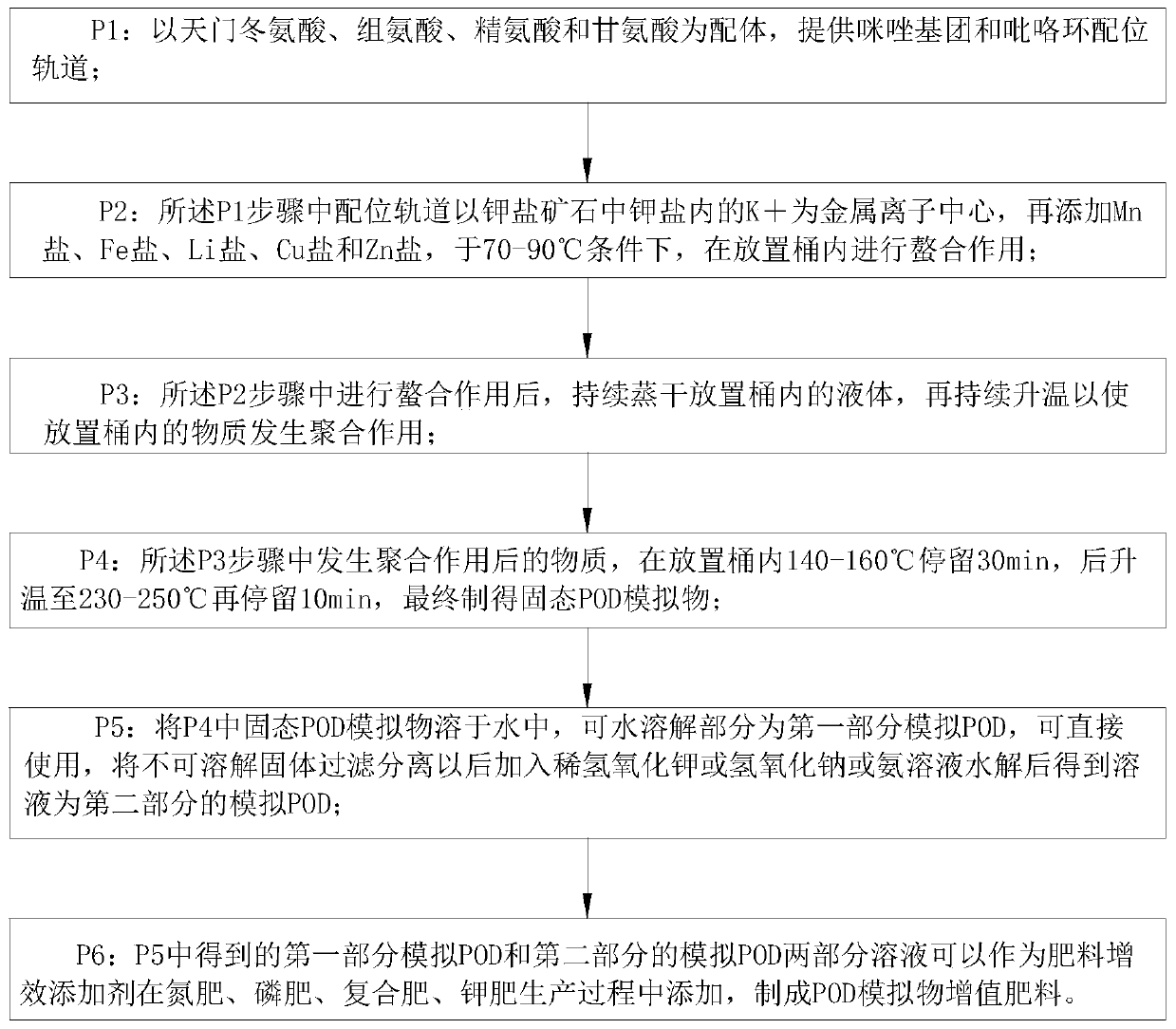

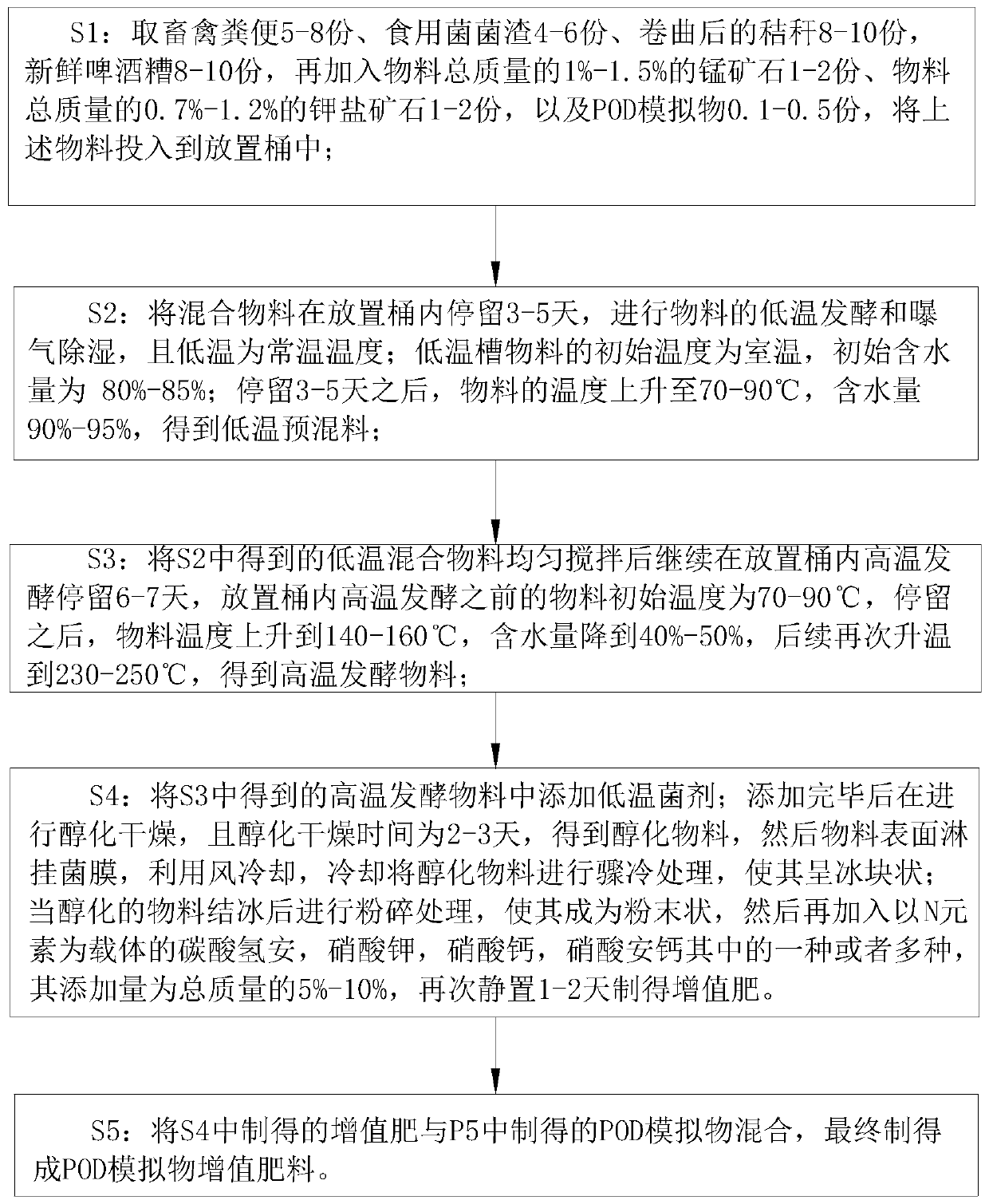

Method used

Image

Examples

Embodiment 1

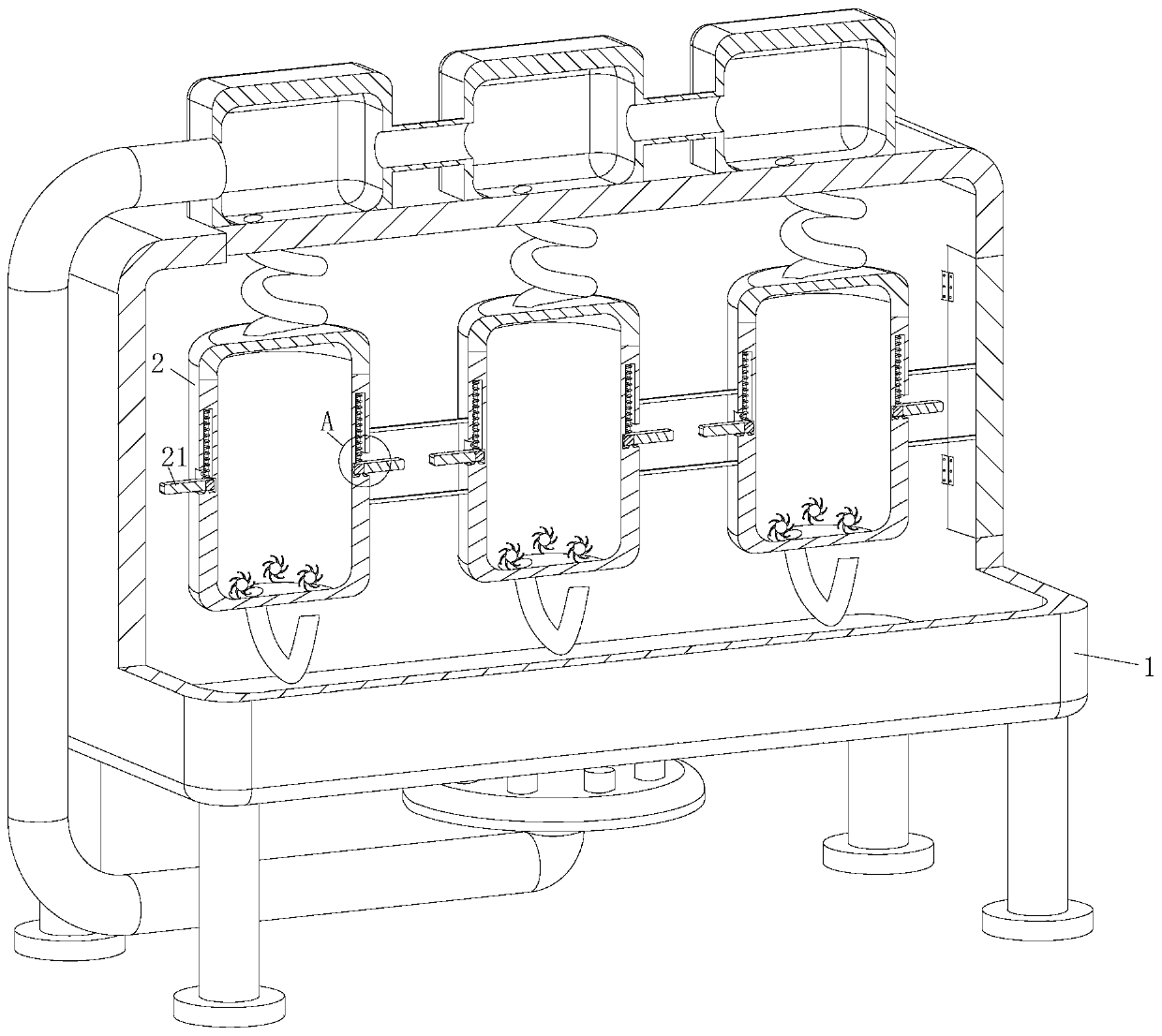

[0055] Take 5 parts of livestock and poultry manure, 4 parts of edible fungus residue, 8 parts of curled straw, 10 parts of fresh brewer's grains, and then add 1 part of manganese ore of 1%-1.5% of the total mass of the material, and 0.7% of the total mass of the material - 1 part of 1.2% potassium salt ore, 0.2 part of POD simulant, put the above materials into the placement barrel 2, stir evenly in the placement barrel 2, place it at low temperature for 4 days, and carry out the fermentation and aeration of the materials , the initial temperature of the low temperature is room temperature, and the initial water content is 82%; after staying for 4 days, the temperature of the material rises to 78°C, and the water content is 93%, to obtain a low-temperature premix, which is then placed for 6 days after stirring. On the 5th day, the biogas was generated in barrel 2, and the biogas was collected into the mixing equipment. After stirring for 6 days, the mixing equipment was heated...

Embodiment 2

[0057] Take 5 parts of livestock and poultry manure, 4 parts of edible fungus residue, 8 parts of curled straw, 10 parts of fresh brewer's grains, and then add 1 part of manganese ore of 1%-1.5% of the total mass of the material, and 0.7% of the total mass of the material - 1 part of 1.2% potassium salt ore, 0.3 part of POD simulant, put the above materials into the placement barrel 2, stir evenly in the placement barrel 2, place it at low temperature for 4 days, and carry out the fermentation and aeration of the materials , the initial temperature of low temperature is room temperature, and the initial water content is 81%; On the 4th day, the biogas was generated in barrel 2, and the biogas was collected into the mixing equipment. After stirring for 6 days, the mixing equipment was heated with biogas combustion. Before heating the mixing equipment, the initial temperature of the material was 81°C. After heating, the material’s The temperature rises to 148°C, and the water co...

Embodiment 3

[0059] Take 5 parts of livestock and poultry manure, 4 parts of edible fungus residue, 8 parts of curled straw, 10 parts of fresh brewer's grains, and then add 1 part of manganese ore of 1%-1.5% of the total mass of the material, and 0.7% of the total mass of the material - 1 part of 1.2% potassium salt ore, 0.4 part of POD simulant, put the above materials into the placement barrel 2, stir evenly in the placement barrel 2, place it at low temperature for 4 days, and carry out the fermentation and aeration of the materials , the initial temperature of the low temperature is room temperature, and the initial water content is 80%; after staying for 4 days, the temperature of the material rises to 82°C, and the water content is 90%, to obtain a low-temperature premix, which is then placed for 6 days after stirring. On the 5th day, the biogas was generated in barrel 2, and the biogas was collected into the mixing equipment. After stirring for 6 days, the mixing equipment was heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com