A kind of aluminum salt microbial composite flocculant for treating shale gas drilling wastewater

A composite flocculant and drilling wastewater technology, which is applied in mining wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of bridging and network repair capacity need to be improved, and improve the coagulation effect. , The effect of improving the chroma removal rate and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

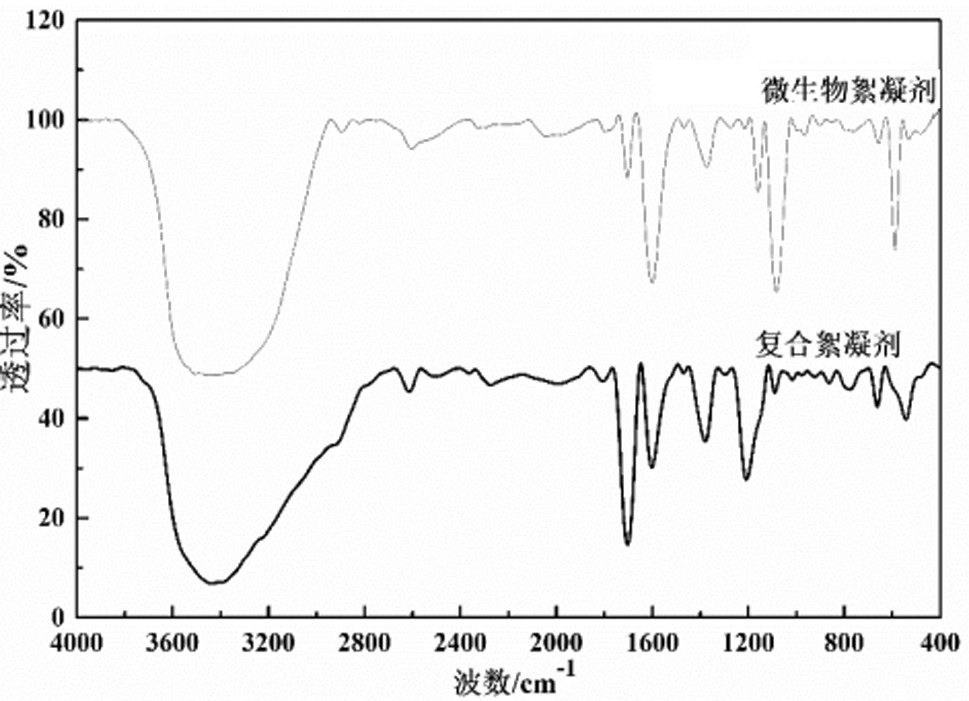

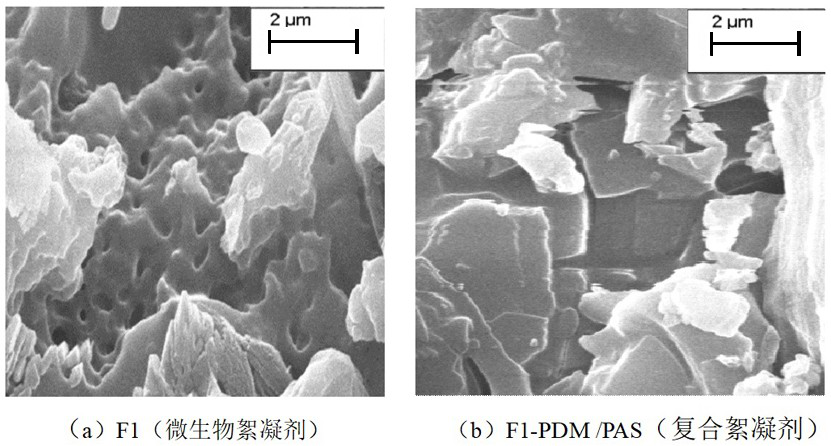

[0030] Prepare industrial-grade aluminum sulfate with a content of 90% aluminum sulfate into a solution with a mass fraction of 20%, filter it, remove impurities, place it in a reactor and heat it to a temperature of 75°C, and then add PDMDAAC with a molecular weight of 2 to 3 million. Among them, aluminum sulfate solution and Al are used in the mixed solution 2 o 3 The mass ratio of meter to PDMDAAC is 30:1, adjust the stirrer to stir at medium speed for 90min, then add the mycobacterial polysaccharide F1 prepared in step S1, the dosage is 0.8% according to the mass ratio, adjust the stirrer to medium speed After stirring for 25 minutes, the prepared solution was dried in an oven at 50°C to obtain Class A aluminum salt microbial composite flocculant, where the aluminum salt microbial composite flocculant is abbreviated as F1-PDM / PAS.

[0031] Wherein F1 is the abbreviation of mycobacterial polysaccharide, so mycobacterial polysaccharide F1 is generally called mycobacterial p...

Embodiment 2

[0033] Prepare industrial-grade aluminum sulfate with a content of 90% aluminum sulfate into a solution with a mass fraction of 20%, filter it, remove impurities, put it in a reactor and heat it to a temperature of 80°C, and then add PDMDAAC with a molecular weight of 2 to 3 million. Among them, aluminum sulfate solution and Al are used in the mixed solution 2 o 3 The mass ratio of meter to PDMDAAC is 30:1, adjust the stirrer to stir at medium speed for 100min, then add the mycobacterial polysaccharide F1 prepared in step S1, the dosage is 1% according to the mass ratio, adjust the stirrer to medium speed After stirring for 25 minutes, the prepared solution was dried in an oven at a temperature of 50° C. to obtain Type B F1-PDM / PAS.

Embodiment 3

[0035] Prepare industrial-grade aluminum sulfate with an aluminum sulfate content of 90% into a solution with a mass fraction of 20%, filter it, remove impurities, place it in a reactor and heat it to a temperature of 85°C, and then add PDMDAAC with a molecular weight of 2 to 3 million. Among them, aluminum sulfate solution and Al are used in the mixed solution 2 o 3 The mass ratio of meter to PDMDAAC is 35:1, adjust the stirrer to stir at medium speed for 100min, then add the mycobacterial polysaccharide F1 prepared in step S1, the dosage is 1.2% according to the mass ratio, adjust the stirrer to medium speed After stirring for 25 minutes, the prepared solution was dried in an oven at a temperature of 50° C. to obtain Type C F1-PDM / PAS.

[0036] Comparison of the same F1-PDM / PAS coagulation test:

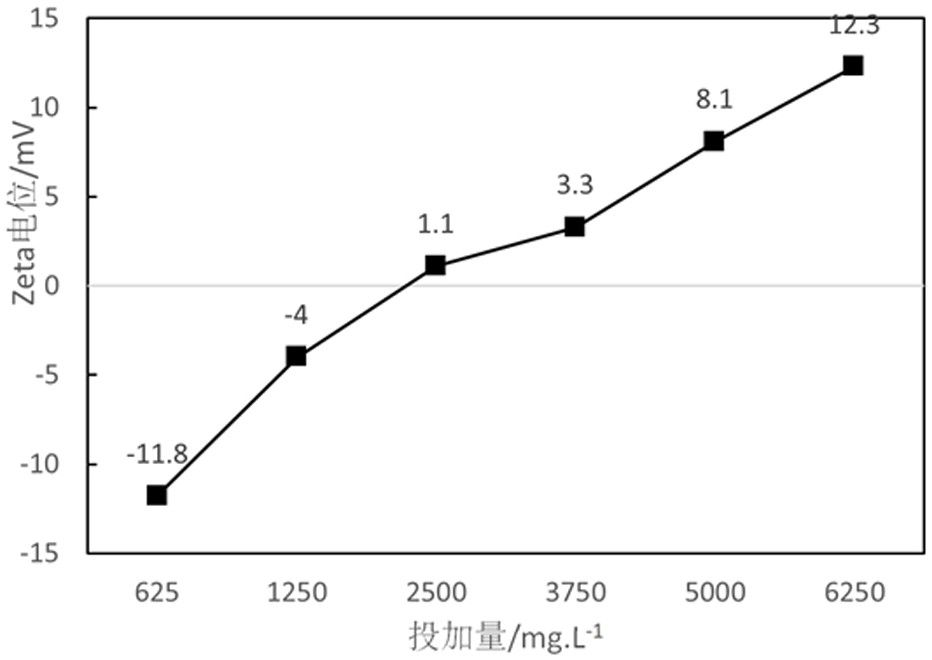

[0037] Put 500 mL of drilling wastewater into six 1 L mixing cups to be tested for coagulation, and set the program at 280r.min -1 Stir for 1min, 800 r.min -1 Stir for 5 min. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com