A kind of vinyl benzophenone macromolecular photoinitiator and preparation method thereof

A technology of p-hydroxybenzophenone and vinyl acetate resin, applied in the field of benzophenone macromolecular photoinitiator and its preparation, can solve the problems of poor system compatibility, low performance photoinitiation efficiency, and high surface mobility , to achieve good adhesion, excellent color development, and reduce surface migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

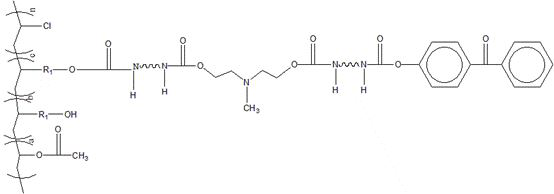

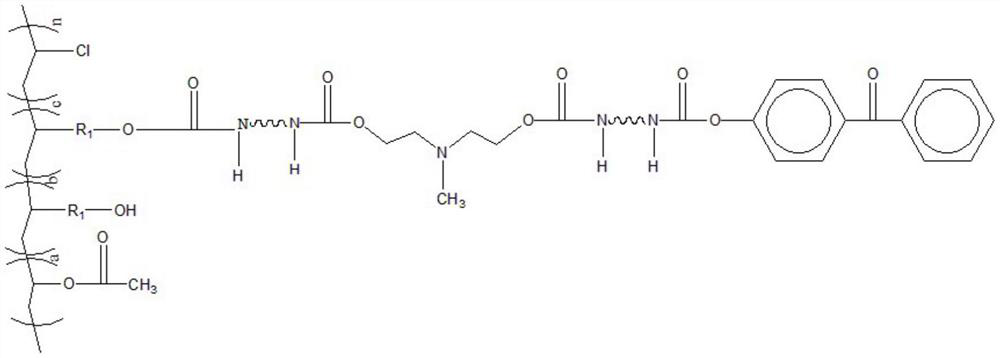

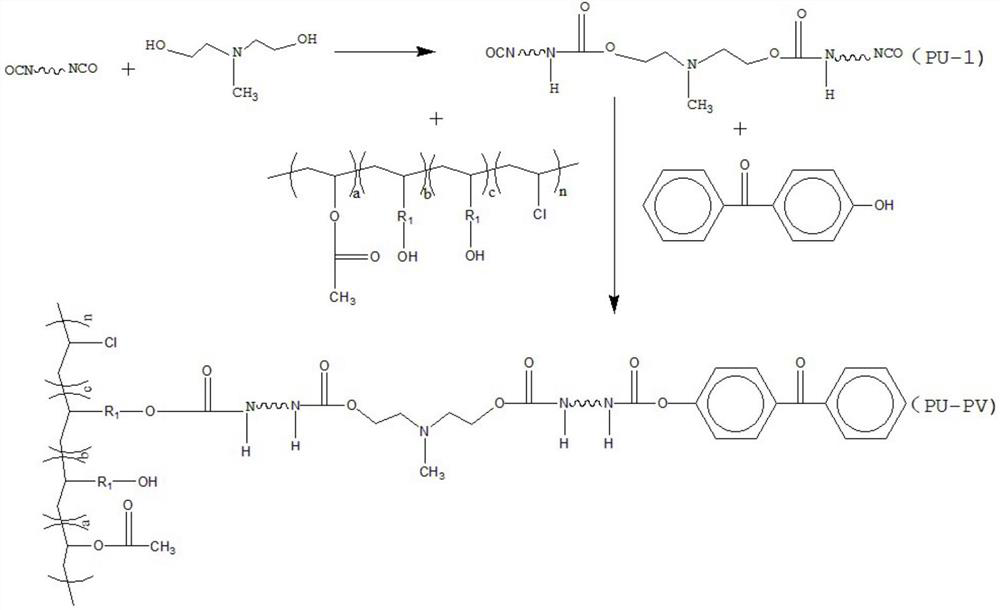

Image

Examples

Embodiment 1

[0026] (a) 4.5 parts of MDI and 2 parts of tin isooctoate are dissolved in 40 parts of ethyl acetate, and 2 parts of N-methyldiethanolamine are dissolved in 20 parts of ethyl acetate and added to the constant pressure dropping funnel, controlled The dropping speed is 4-5s / drop, and after magnetic stirring at room temperature for 4 hours, the reaction is stopped when the hydroxyl group disappears by infrared detection, and the ethyl acetate solution of the intermediate product PU-1 is obtained.

[0027] (b) Dissolve 1.7 parts of p-hydroxybenzophenone in 20 parts of ethyl acetate and add it to the constant pressure dropping funnel, control the dropping speed of 4-5s / drop, and add dropwise to the acetic acid of the completely dissolved PU-1 In the ethyl ester solution, the molar ratio of PU-1 to p-hydroxybenzophenone is 1:1. After the dripping, continue to stir magnetically for 0.5h, and then use a constant pressure dropping funnel to continue dripping 1 part of hydroxy ternary 1...

Embodiment 2

[0029] (a) 4 parts of TDI, 2 parts of stannous octoate are dissolved in 40 parts of ethyl acetate, 2 parts of N-methyldiethanolamine are dissolved in 20 parts of ethyl acetate and join in the constant pressure dropping funnel, control The dropping speed is 4-5s / drop, and after magnetic stirring at room temperature for 2 hours, the infrared detection detects that the hydroxyl group disappears and the reaction is stopped, and the ethyl acetate solution of the intermediate product PU-1 is obtained.

[0030] (b) Dissolve 1.5 parts of p-hydroxybenzophenone in 20 parts of ethyl acetate and add it to the constant pressure dropping funnel, control the dropping speed of 4-5s / drop, and add dropwise to the acetic acid of the completely dissolved PU-1 In the ethyl ester solution, the molar ratio of PU-1 to p-hydroxybenzophenone is 1:1. After the dripping, continue to stir magnetically for 0.5h, and then use a constant pressure dropping funnel to continue dripping 1 part of hydroxy ternary ...

Embodiment 3

[0032] (a) Dissolve 4.5 parts of HDI and 2 parts of dibutyltin dilaurate in 40 parts of ethyl acetate, 2 parts of N-methyldiethanolamine in 20 parts of ethyl acetate and add them to the constant pressure dropping funnel , control the dropping speed to 4-5s / drop, and stir magnetically at room temperature for 3 hours, and stop the reaction when the hydroxyl group disappears by infrared detection, and obtain the ethyl acetate solution of the intermediate product PU-1.

[0033] (b) Dissolve 1.6 parts of p-hydroxybenzophenone in 20 parts of ethyl acetate and add it to the constant pressure dropping funnel, control the dropping speed of 4-5s / drop, and add dropwise to the acetic acid of the completely dissolved PU-1 In the ethyl ester solution, the molar ratio of PU-1 to p-hydroxybenzophenone is 1:1. After the dripping, continue to stir magnetically for 0.5h, and then use a constant pressure dropping funnel to continue dripping 1 part of hydroxy ternary 10 parts of ethyl acetate solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com