IPMC (ion-exchange polymer metal composite) medical catheter and manufacture method thereof

A catheter and solid electrolyte technology, applied in the direction of catheters, etc., can solve the problems of electromagnetic field-driven catheters lack of theoretical support, difficult to use actual surgery, patient discomfort, etc., to achieve precise and controllable multi-motion degrees of freedom bending and guiding characteristics, efficient minimally invasive intervention Positioning technology, good effect with biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

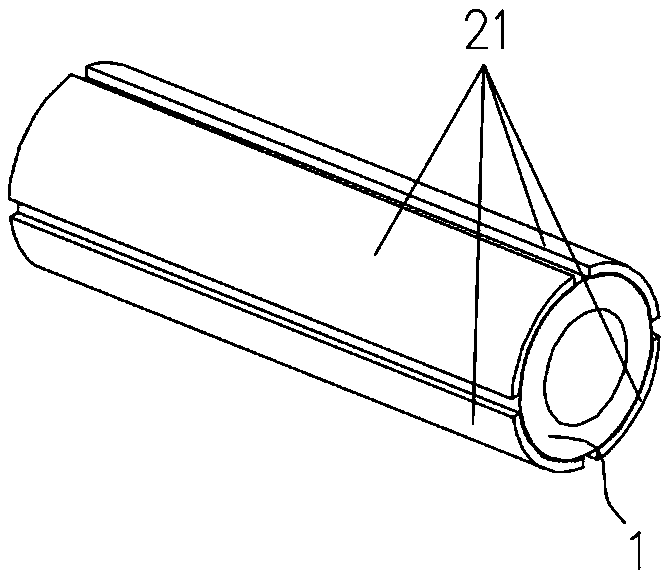

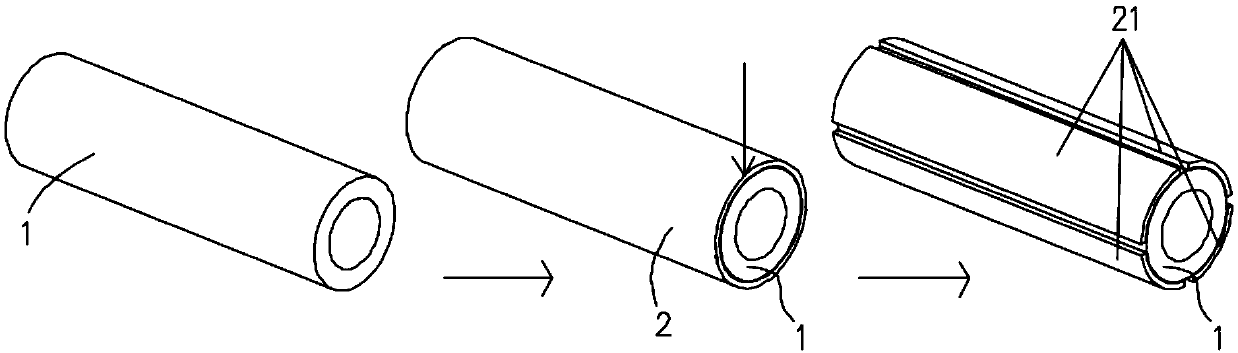

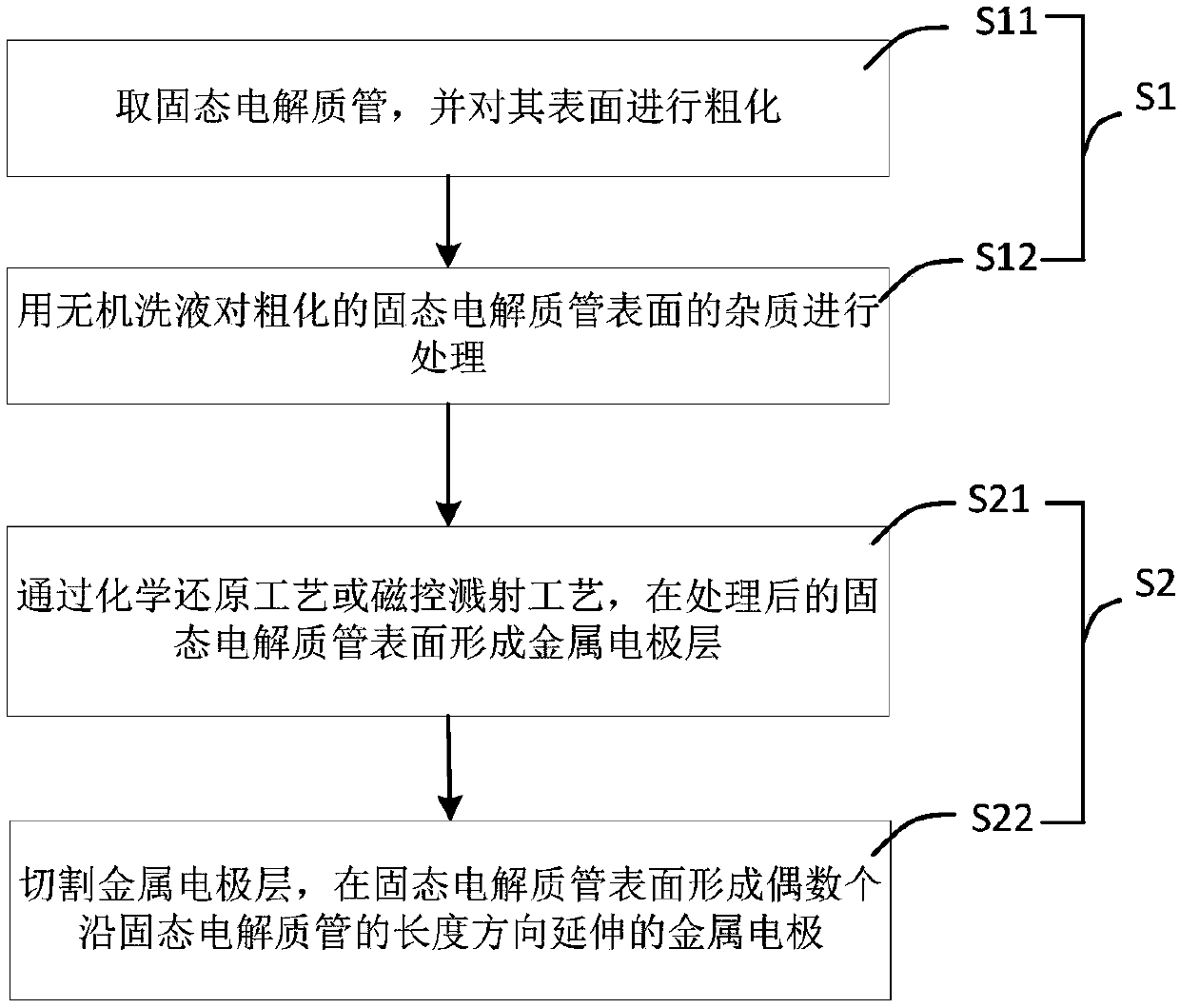

[0046] see image 3 , the present embodiment also provides a preparation method for preparing the above-mentioned IPMC medical catheter, wherein the IPMC medical catheter includes a solid electrolyte tube and an even number of metal electrodes coupled with the solid electrolyte tube, and the preparation method includes the steps :

[0047] S1. Take the solid electrolyte tube, and process the surface of the solid electrolyte tube to obtain the treated solid electrolyte tube;

[0048] Specifically, refer to image 3 , step S1 includes:

[0049] S11. Take a solid electrolyte tube, and roughen the surface of the solid electrolyte tube to obtain a roughened solid electrolyte tube; wherein, the surface roughening can be achieved by sanding or plasma etching;

[0050] S12. Treat impurities on the surface of the roughened solid electrolyte tube with an inorganic washing solution to obtain a treated solid electrolyte tube. Wherein, the inorganic lotion is one or more of deionized w...

Embodiment 1

[0065] The implementation steps of this embodiment are as follows:

[0066] 11. Take the solid electrolyte and roughen its surface; the solid electrolyte tube in this embodiment is a perfluorosulfonic acid tube, which is made by solution casting and has a transparent color. Use 1200 mesh sandpaper to polish the perfluorosulfonic acid tube for 600° Second, roughen the surface.

[0067] 12. Treat the impurities on the surface of the roughened solid electrolyte tube; ultrasonically clean the polished perfluorosulfonic acid tube for 3 times with dilute sulfuric acid and deionized water respectively (interleaved cleaning with dilute sulfuric acid and deionized water, respectively), each time 10min, the purpose is to remove debris attached to the surface of the material and other easily detachable impurities. Under a water bath at 75°C, the perfluorosulfonic acid tube was washed three times with hydrogen peroxide solution to remove organic impurities.

[0068] 13. Forming a metal ...

Embodiment 2

[0084] The implementation steps of this embodiment are as follows:

[0085] 21. Take the solid electrolyte and roughen its surface; the solid electrolyte tube in this embodiment is a perfluorosulfonic acid tube made by solution casting method, the color is transparent, and the density is 1.27g / cm 3 , the molar mass is 356g / mol, and the ionic conductivity is 1.2×10 -4 S / cm, surface roughening of perfluorosulfonic acid tubes by plasma etching process.

[0086] 22. Treat the impurities on the surface of the roughened solid electrolyte tube; ultrasonically clean the polished perfluorosulfonic acid tube once with sodium hydroxide solution, sodium chloride solution and deionized water, each time for 10 minutes, in order to remove The debris attached to the surface of the material is easy to get rid of impurities. Under a water bath at 65°C, the perfluorosulfonic acid tube was washed three times with hydrogen peroxide solution to remove organic impurities.

[0087] 23. Forming a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com