A kind of treatment method containing para-ester wastewater

A treatment method and para-ester technology are applied in the field of treatment of para-ester dye intermediate wastewater, which can solve the problems of uninspected biochemical section operation status, low COD of source wastewater, poor practicability, etc., so as to improve the biochemical ability of wastewater The effect of low dosage, low dosage and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

[0029] The para-ester wastewater of a dye intermediate factory adopts the method of the present invention: mixed water + micro-electrolysis + catalytic oxidation + coagulation precipitation + A / O / O + biological denitrification pool method, the specific steps are as follows

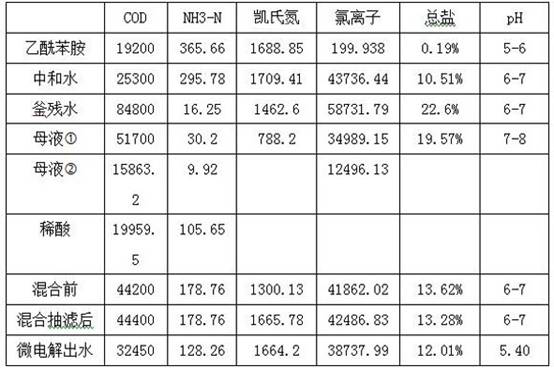

[0030] Raw water quality index

[0031]

[0032] (1) Acetanilide water, neutralization water, residual water, and mother liquor water are prepared in a ratio of 1:8:3:8 to 1L. After mixing, a large number of white crystals are produced. The pH of the mixed water is 6~7. After filtering, use waste acid to adjust the pH to 2, and perform micro-electrolysis. The micro-electrolysis filler is angle steel, and the reaction time is 2 hours.

[0033]

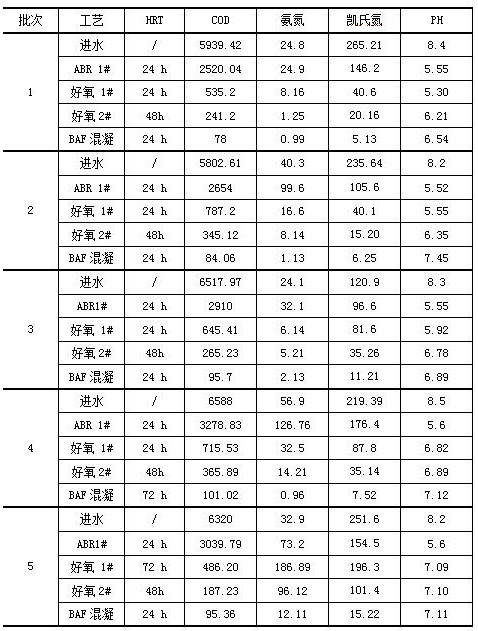

[0034] (2) Add 1% hydrogen peroxide to the effluent of micro-electrolysis for catalytic oxidation to improve biodegradability. After the effluent is diluted, the A / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com