Compound, organic light-emitting device, display panel and display device

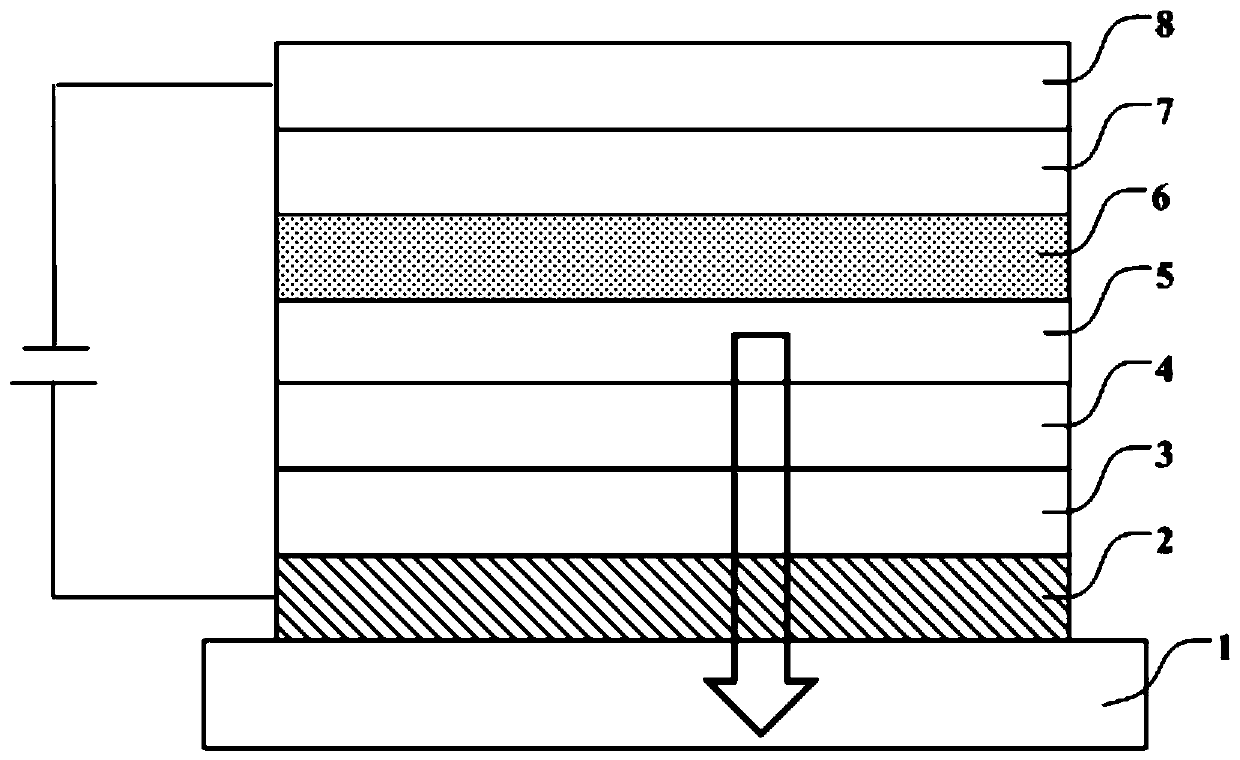

A compound and electromechanical technology, applied in the field of compounds, organic electroluminescent devices, display panels and display devices, to achieve the effect of widening the light emitting area, high luminous efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

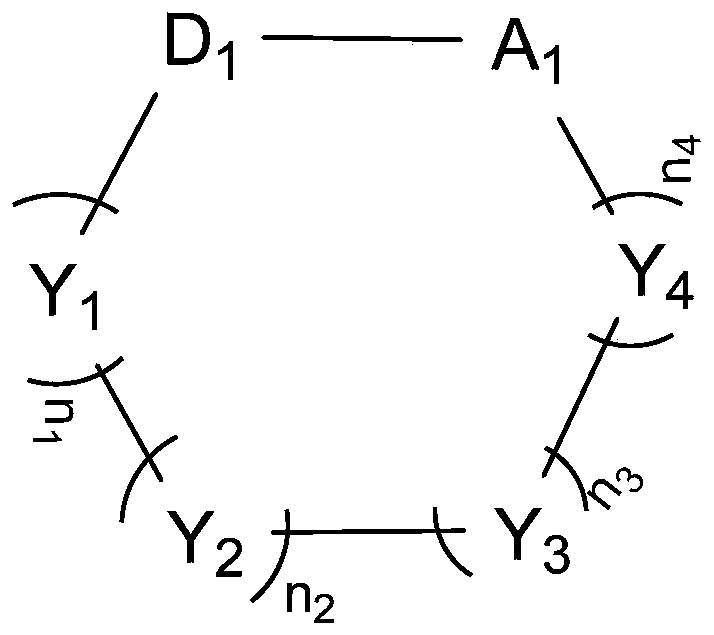

Method used

Image

Examples

preparation example 1

[0104] Compound M5 was prepared by the following method:

[0105]

[0106] (1) Dissolve compound S1 (20mmol) in 80mL tetrahydrofuran (THF), cool to -78°C, add 31.25mL n-butyllithium solution (1.6M, hexane, 50mmol) to the solution, and stir at -78°C 2h. Then 20 mL of S2 (60 mmol) was added to the solution, the temperature was slowly raised to room temperature, and stirred for 4 h. Water was added to the solution and extracted with ether. The extracted organic phase was washed with water, and anhydrous MgSO was added 4 dry. Purification was carried out by silica gel column chromatography, using dichloromethane:n-hexane (1:9) as the eluent, and finally the eluent was distilled under reduced pressure to obtain the product S3 (18 mmol, 90%).

[0107] MALDI-TOF MS: C 42 h 40 N 2 sn 2 : m / z calculated value: 812.1; tested value: 812.3.

[0108]

[0109] (2) Under nitrogen protection, weigh compounds S3 (126 μmol), S4 (126 μmol), Pd 2 (dba) 3 (6.3μmol) and (tBu) 3 P ...

preparation example 2

[0113] Compound M7 was prepared by the following method:

[0114]

[0115] (1) Dissolve compound S5 (25mmol) in 100mL THF, cool to -78°C, add 40mL n-butyllithium solution (1.6M in hexane, 64mmol) to the solution, and stir at -78°C for 2h. Then 25 mL of S2 (75 mmol) was added to the solution, the temperature was slowly raised to room temperature, and stirred for 4 h. Water was added to the solution and extracted with ether. The extracted organic phase was washed with water, and anhydrous MgSO was added 4 dry. Purification was performed by silica gel column chromatography, using dichloromethane:n-hexane (1:9) as the eluent, and finally the eluent was distilled under reduced pressure to obtain the product S6 (23.75 mmol, 95%).

[0116] MALDI-TOF MS: C 24 h 29 NSn 2 : m / z calculated value: 571.0; tested value: 571.2.

[0117]

[0118] (2) Under nitrogen protection, weigh compounds S6 (160 μmol), S7 (160 μmol), Pd 2 (dba) 3 (8μmol) and (tBu) 3 P (8μmol) and KOtBu (4...

preparation example 3

[0122] Compound M24 was prepared by the following method:

[0123]

[0124] (1) Under nitrogen protection, weigh compounds S6 (104 μmol), S8 (104 μmol), Pd 2 (dba) 3 (5.2μmol) and (tBu) 3 P (5.2μmol) and KOtBu (300μmol) were added to a 500mL two-necked flask. Inject 100mL of toluene into the two-necked flask (pass N in advance 2 15min to remove oxygen), reflux and stir overnight. After the reaction, cool down, distill under reduced pressure, concentrate the solution to 25 mL, add 15 mL of deionized water, and drop a few drops of 2M HCl to remove the salt therein. Extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel chromatography to remove the Pd catalyst. The eluate was collected, concentrated, and purified using size exclusion chromatography using THF as e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com