Preparation method of fluorescent reinforced metal nano cluster/zeolite imidazate framework composite nano material and application thereof

A technology of metal nanoclusters and composite nanomaterials is applied in the field of fluorescent materials to achieve the effects of strong universality, low energy consumption and excellent fluorescent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

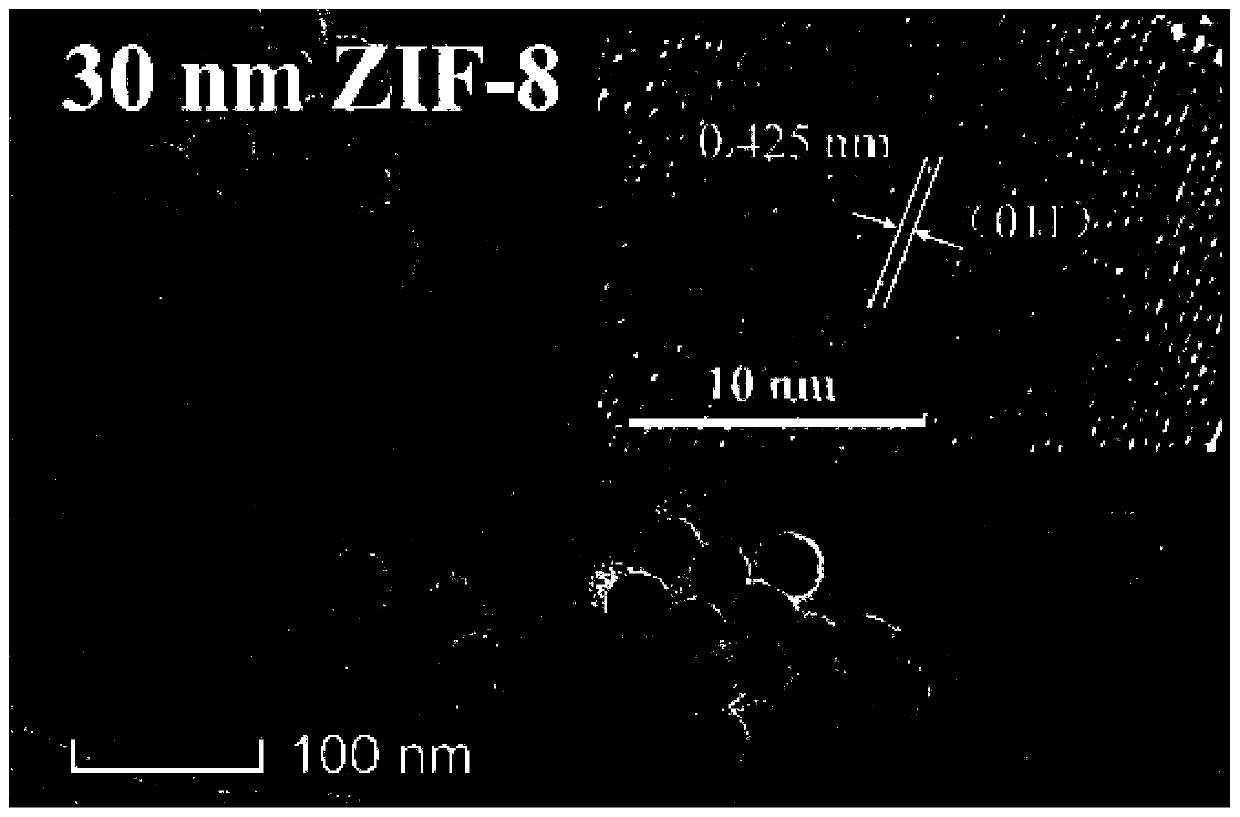

[0036] In this embodiment, the preparation method of fluorescence-enhanced metal nanocluster / zeolite imidazolate framework composite nanomaterial is GSH-Au NCs / ZIF-8 composite material, and the preparation process is as follows:

[0037] Preparation of ZIF-8:

[0038] Weigh 888mg of zinc nitrate hexahydrate (Zn(NO) 3 ·6H 2 (2) and 1946.7mg 2-methylimidazole (2-mIM) were dissolved in 60mL of methanol respectively, and the two were mixed in a 250mL round-bottomed flask, and reacted at room temperature 1000rpm for 1h on a magnetic stirrer, and the obtained milk Centrifuge the turbid liquid to obtain a white precipitate, discard the supernatant, wash the white precipitate with methanol three times, and place it in a vacuum oven at 50°C for 12 hours. The dried white powder is ZIF-8;

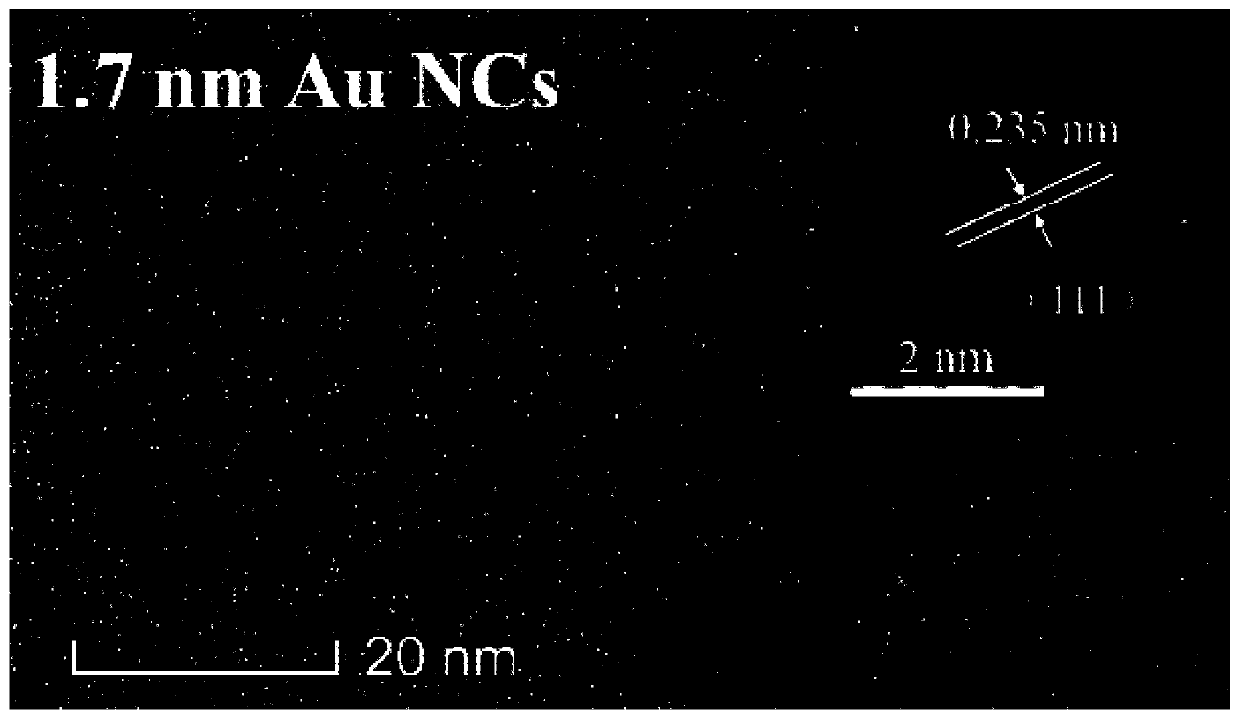

[0039] Preparation of GSH-Au NCs:

[0040] Take a 10mL round bottom flask with a built-in magnet, add 4.35mL of ultrapure water, stir at room temperature at 500rpm, add 0.15mL of 100mM GSH aqueous ...

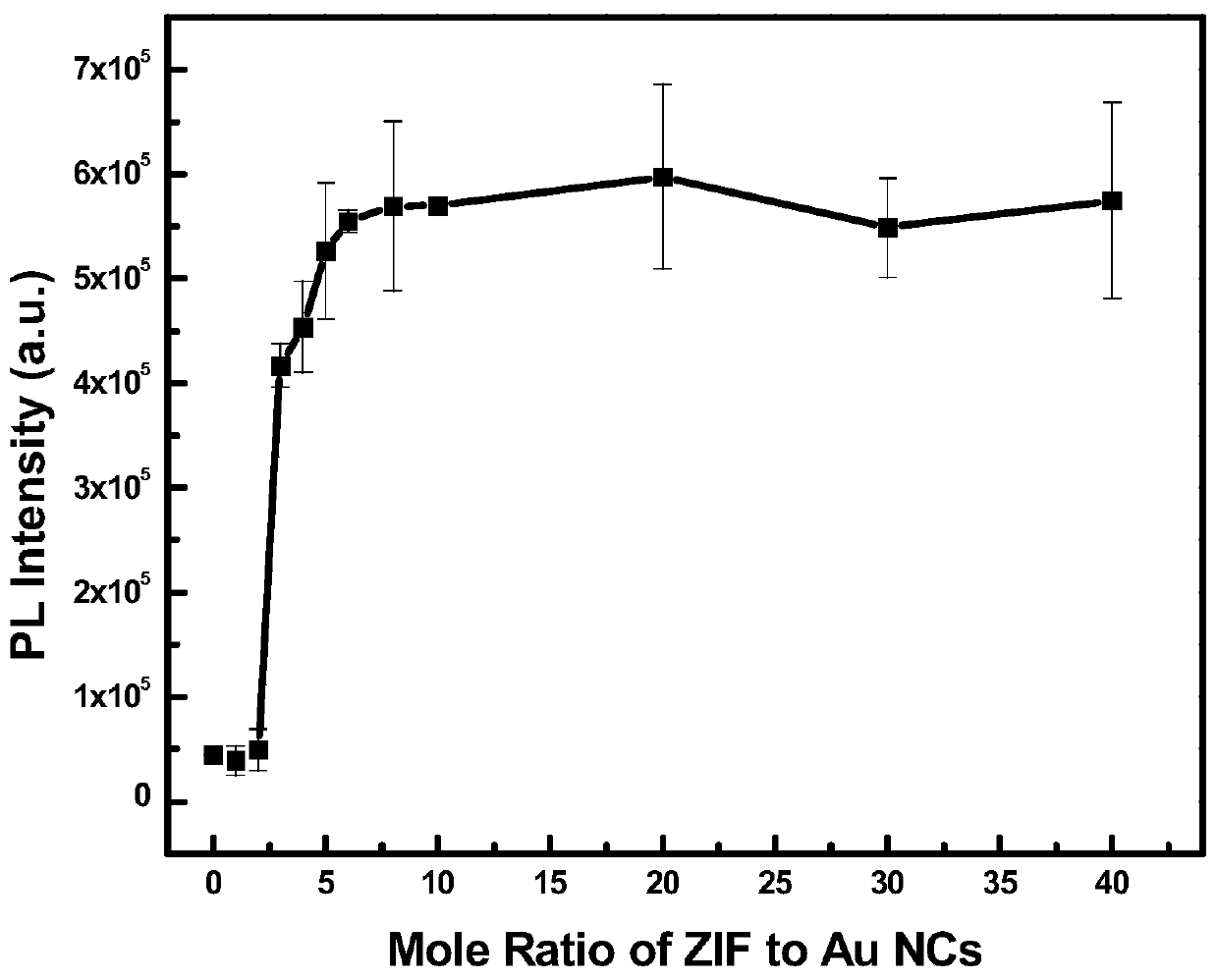

Embodiment 2

[0044] In this embodiment, the preparation method of fluorescence-enhanced metal nanocluster / zeolite imidazolate skeleton composite nanomaterial is GSH-Au NCs / ZIF-8 composite material, and its preparation process is the same as that of Example 1, except that ZIF -8 and GSH-AuNCs according to the ratio of Zn:Au=4 were ultrasonicated for 1 h at 30°C to make them assemble, and the GSH-Au NCs / ZIF-8 composite was obtained.

Embodiment 3

[0046] In this embodiment, the preparation method of fluorescence-enhanced metal nanocluster / zeolite imidazolate skeleton composite nanomaterial is GSH-Au NCs / ZIF-8 composite material, and its preparation process is the same as that of Example 1, except that ZIF -8 and GSH-AuNCs according to the ratio of Zn:Au=5 were ultrasonicated at 30°C for 1 h to make them assemble, and the GSH-Au NCs / ZIF-8 composite was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com