Process system for preparing biodiesel by stepped reverse-flow type continuous enzymatic method

A biodiesel and process system technology, which is applied in the field of process systems for preparing biodiesel by a step-counter-flow continuous enzymatic method, can solve the problems of substandard product acid value, incomplete reaction, slow biodiesel reaction rate, etc., and achieve production cost. Improve, avoid input, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] According to the process system of the present invention, do a small test to prepare biodiesel:

[0036] a. 100g waste oil with an acid value of 76mgKOH / g oil, the standard enzyme activity of Candida antarctica based on the unit oil mass of 360, and 10g of anhydrous methanol chemically pure were placed in a flask, and the flask was placed in a 40°C water bath with a stirring speed of 200rpm. The reaction time is 3 hours.

[0037] b. Take out the reaction product, centrifuge, centrifuge 21 speed 4500rpm, take the upper layer oil phase after centrifugation and put it in another flask after being filtered by ceramic membrane, add anhydrous methanol 6g, Candida antarctica based on unit oil in the flask The quality standard enzyme activity is 200, the flask is placed in a 40°C water bath, the stirring speed is 200rpm, and the reaction time is continued for 3 hours. At the same time, the centrifugal heavy phase is filtered through a 75um metal membrane and a 25um ceramic memb...

Embodiment 2

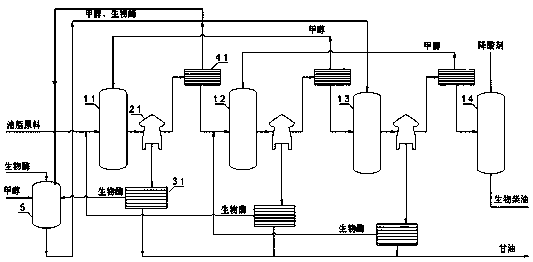

[0047] The multi-stage enzymatic reactor used is 4 stages, and the volume of each stage of the reactor is 0.5L, and the reactor is stirred by a turbine stirrer; the acid reduction reactor adopts a reactor with a volume of 1L, and the reactor jacket is continuously fed into Warm water, stirring with a turbine agitator in the kettle; centrifuge 21 rotating speed 4500r / min, heavy phase membrane filter 31 adopts 75um metal membrane and 25um ceramic membrane in series; oil phase membrane filter 41 adopts 15um ceramic membrane; mixing tank 5 for 1L. cling to figure 1 Connect all the equipment, the pipeline is made of stainless steel 304, the inner diameter of the tube is 6mm, and the wall thickness is 2mm.

[0048] 2000g waste oil with an acid value of 76mgKOH / g oil, Candida antarctica based on the standard enzyme activity of 360 per unit oil mass, and 200g of chemically pure anhydrous methanol were mixed and transported to the first-stage reactor. At the same time, 200g of chemica...

Embodiment 3

[0054] The device used is the same as Example 2, and the multistage enzymatic reactor is changed to three stages.

[0055] Mix 2000g hogwash oil (acid value 7mgKOH / g oil), thermophilic fungus standard enzyme activity 400 based on unit oil mass, and 200g chemically pure anhydrous methanol, then transport them to the first-stage reactor, and simultaneously transfer 200g chemically pure anhydrous methanol Mix it with Candida antarctica standard enzyme activity 360 based on the unit oil mass, add it into the final reactor, and start the reaction at a stirring speed of 200 rpm.

[0056] After the oil phase is recovered from the final reactor, the feed to the primary reactor is changed to only adding oil raw materials, and 80 g of ethylenediamine is added dropwise to the acid reduction reaction kettle, and the dropwise addition is completed in 1 hour. Add 80g of ethylenediamine again in the dropwise addition bottle.

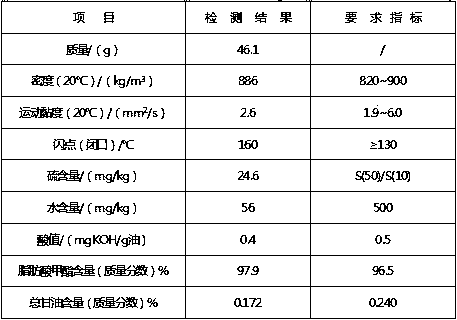

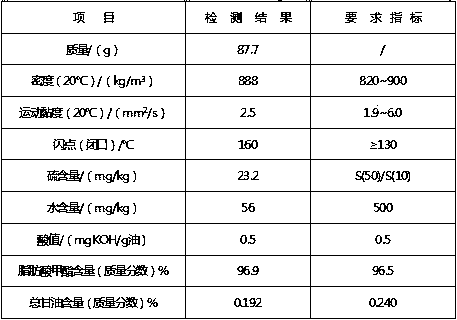

[0057] After receiving 100g of the material from the acid reduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com