Method for leaching copper in waste printed circuit board by virtue of glycine solution

A printed circuit board, glycine technology, applied in the direction of improving process efficiency, can solve problems such as damage, acid waste liquid needs additional treatment, improper operation, etc., to achieve the effect of high leaching efficiency, convenient subsequent treatment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

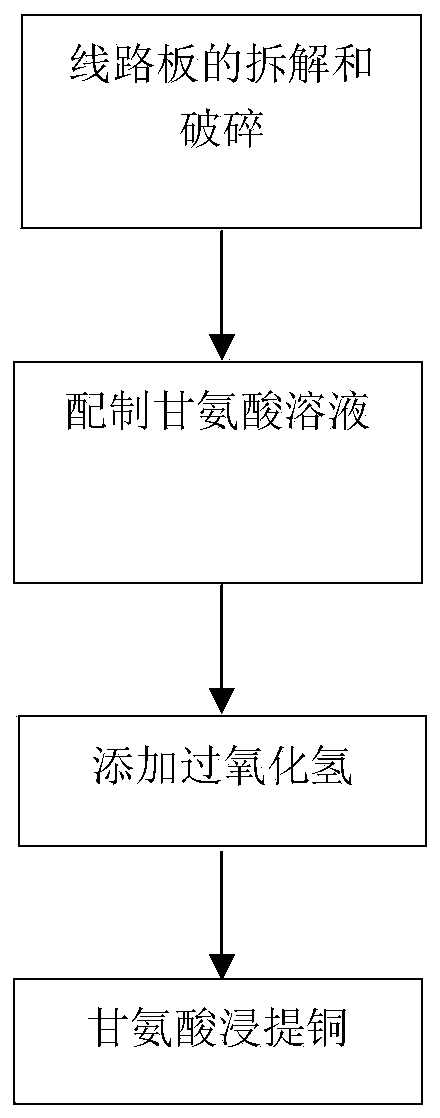

Method used

Image

Examples

Embodiment 1

[0024] Firstly, the waste printed circuit boards are manually dismantled, and then crushed to a particle size of ≤1 mm with a biaxial shear and a crusher. Then prepare a glycine solution in a 500mL beaker, stir it with a glass rod, add hydrogen peroxide, and set the volume to 200mL with ultrapure water, stir evenly with a magnetic stirring bar, and finally obtain a concentration of 1mol / L glycine and a volume fraction of 2.5%. A mixed solution of hydrogen peroxide is used as a leaching agent. Add the crushed waste printed circuit board powder, the ratio of the powder to the leaching agent is 5g / L, the temperature is controlled at 30°C, and the magnetic stirrer is continuously stirred and leached for 480min, and the obtained mixture is diluted by centrifugal filtration to measure the copper content. The leaching rate of copper was calculated to be 78.65%.

Embodiment 2

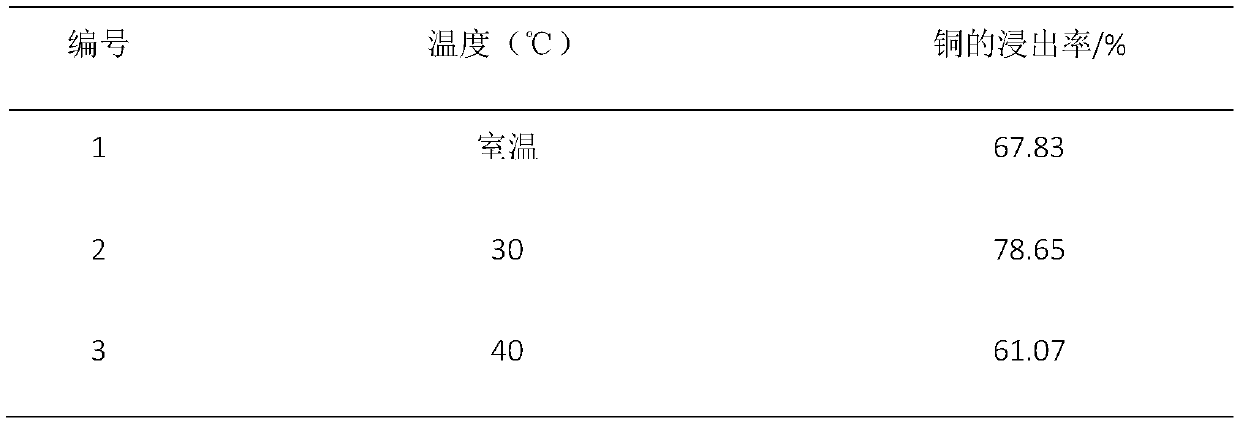

[0026] Other conditions are consistent with embodiment 1, carry out experiment at different temperatures, and concrete result is as follows:

[0027] Table 1 Experiments at different temperatures

[0028]

[0029]

[0030] It can be seen from Table 1 that the copper leaching effect is better at room temperature to 40°C, and the copper leaching effect is best at 30°C, and the preferred temperature is 30°C.

Embodiment 3

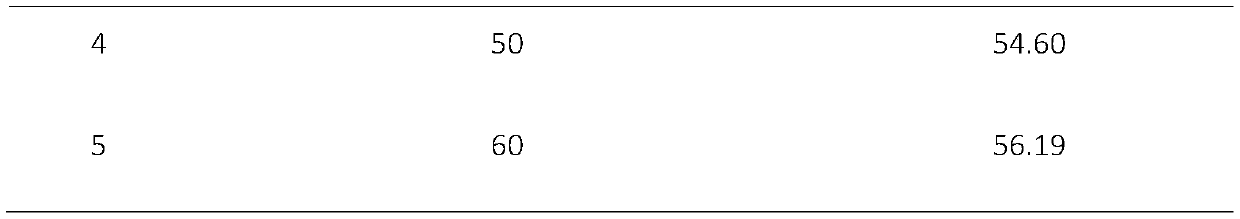

[0032] Other conditions are consistent with embodiment 1, mix different volume fraction hydrogen peroxide in leaching agent and carry out experiment, concrete result is as follows:

[0033] Table 2 Experiments of different hydrogen peroxide concentrations

[0034]

[0035] It can be seen from Table 2 that when the volume fraction of hydrogen peroxide in the leaching agent is 5.0-10%, the leaching effect of copper is better, and when the volume fraction of hydrogen peroxide in the leaching agent is 10%, the leaching effect of copper is the best, and peroxide is preferred. The hydrogen volume fraction is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com