Preparation method of efficient sensing electrode of lactic acid sensor

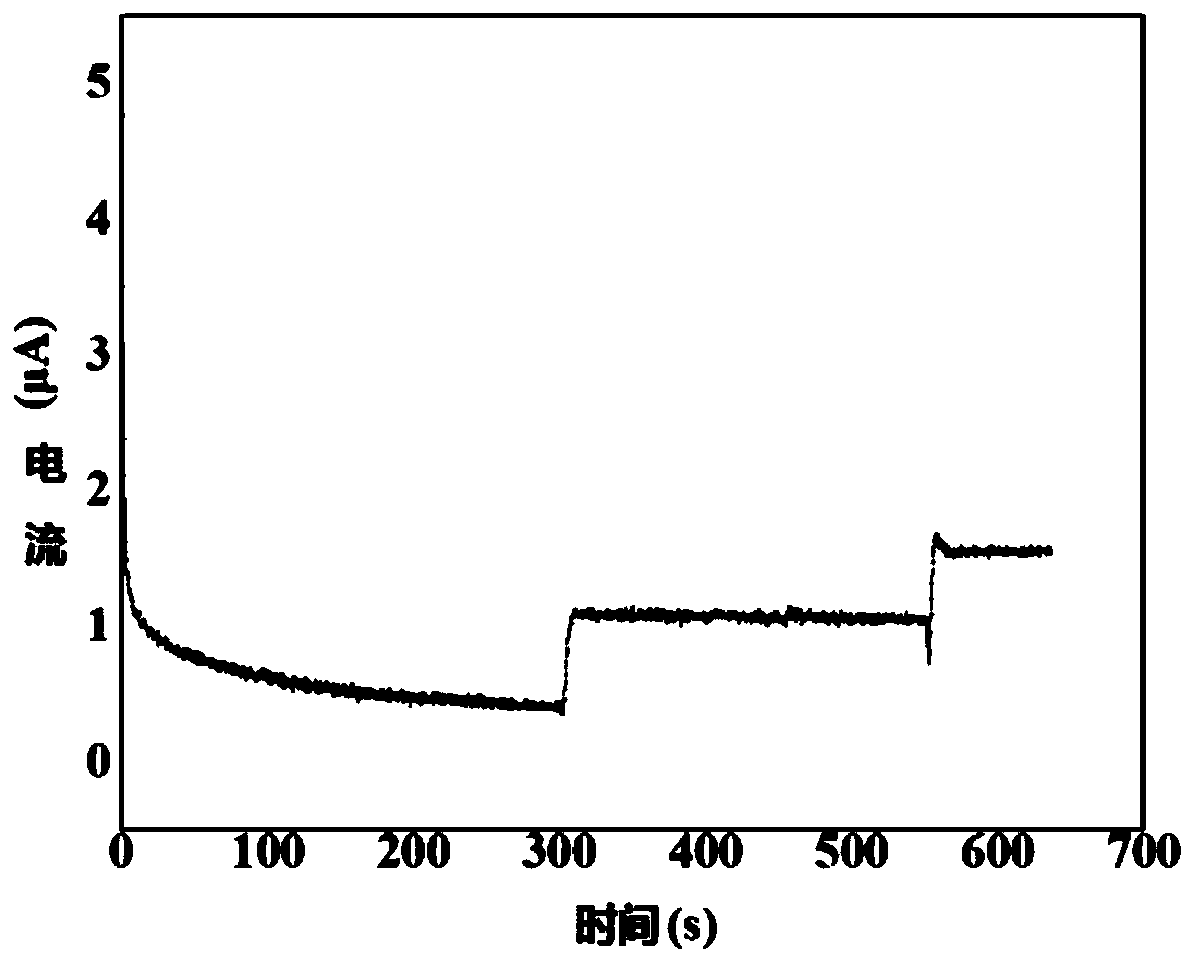

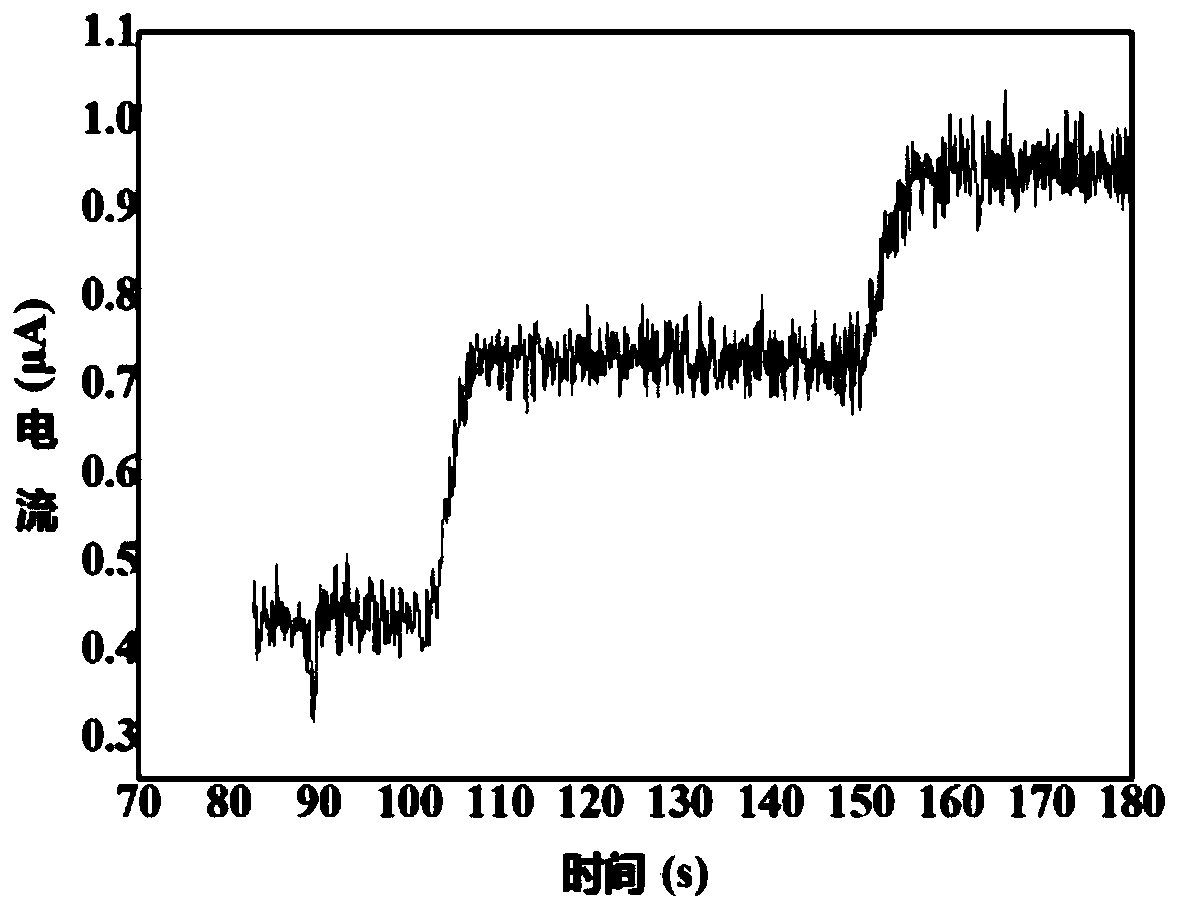

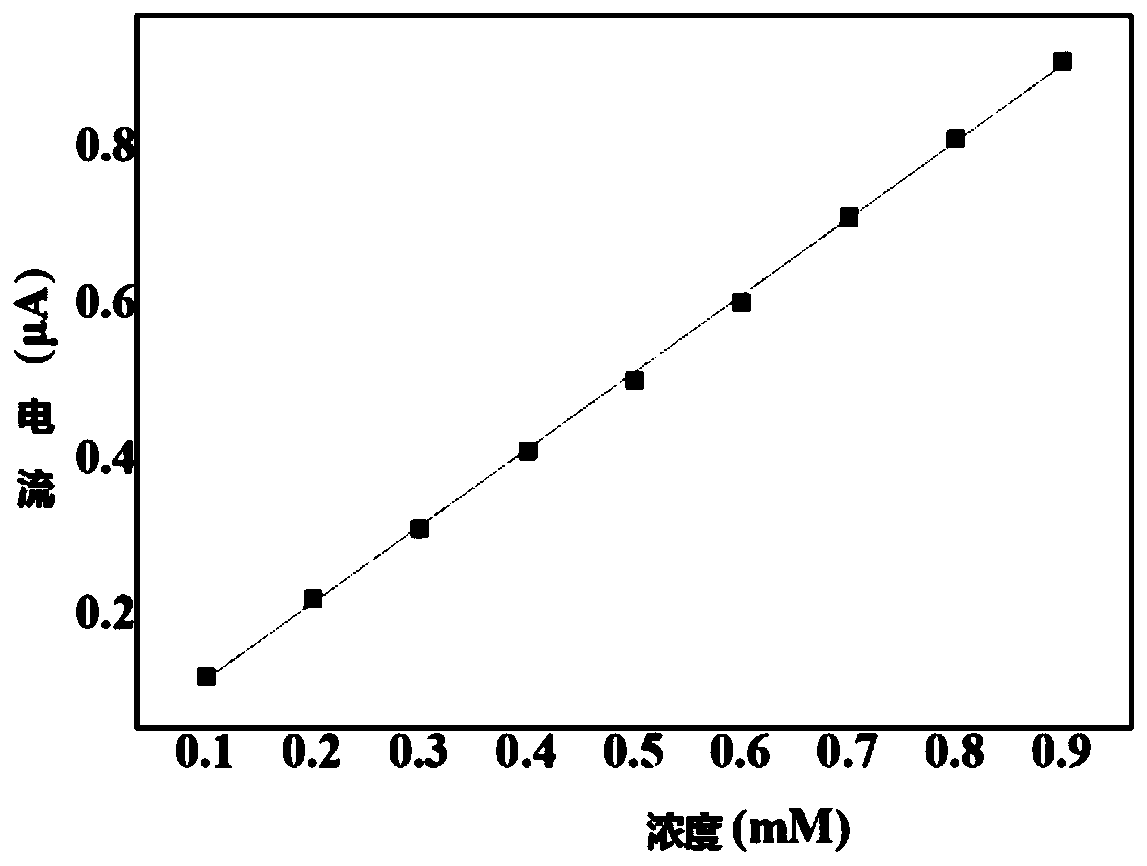

A sensing electrode and sensor technology, applied in the field of biosensors, can solve the problems of unsatisfactory detection, expensive detection reagents, cumbersome sample processing, etc., and achieve the effect of making up for low detection accuracy, high linear detection limit, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 of the present invention provides a high-efficiency sensing electrode for a lactic acid sensor, the preparation method of which includes the preparation of LOX protease and the preparation process of electrode materials;

[0071] The preparation process of electrode materials includes the preparation process of graphene oxide and graphene quantum dot composite materials and the treatment process of glassy carbon electrodes;

[0072] The graphene oxide and graphene quantum dot composite material is prepared by dissolving graphene oxide and graphene quantum dots in ultrapure water at a concentration of 1.3 mg / mL, ultrasonicating for 2 hours; then reacting the resulting solution at 180°C for 14 hours; Then the reaction solution was centrifuged at 8000rpm for 6h; then it was dried in a vacuum oven at 60°C for 14h;

[0073] The particle size of graphene quantum dots is 5nm, the sheet diameter of graphene oxide is 250nm, and the weight ratio of graphene oxide to ...

Embodiment 2

[0088] Embodiment 2 of the present invention provides a high-efficiency sensing electrode for a lactic acid sensor, the preparation method of which includes the preparation of LOX protease and the preparation process of electrode materials;

[0089] The preparation process of electrode materials includes the preparation process of graphene oxide and graphene quantum dot composite materials and the treatment process of glassy carbon electrodes;

[0090] The graphene oxide and graphene quantum dot composite material is prepared by dissolving graphene oxide and graphene quantum dots in ultrapure water at a concentration of 2 mg / mL and ultrasonicating for 5 hours; then reacting the resulting solution at 200°C for 20 hours; then Centrifuge the resulting solution at 10000rpm for 9h; then dry it in a vacuum oven at 75°C for 20h;

[0091] The particle size of graphene quantum dots is 9nm, the sheet diameter of graphene oxide is 300nm, and the weight ratio of graphene oxide to graphene...

Embodiment 3

[0102] Embodiment 3 of the present invention provides a high-efficiency sensing electrode for a lactic acid sensor, the preparation method of which includes the preparation of LOX protease and the preparation process of electrode materials;

[0103] The preparation process of electrode materials includes the preparation process of graphene oxide and graphene quantum dot composite materials and the treatment process of glassy carbon electrodes;

[0104] The graphene oxide and graphene quantum dot composite material is prepared by dissolving graphene oxide and graphene quantum dots in ultrapure water at a concentration of 0.8 mg / mL and ultrasonicating for 1 h; then reacting the resulting solution at 150°C for 10 h; Then the reaction solution was centrifuged at 6000rpm for 3h; then it was dried in a vacuum oven at 45°C for 10h;

[0105] The particle size of graphene quantum dots is 3nm, the sheet diameter of graphene oxide is 150nm, and the weight ratio of graphene oxide to graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com