Lithium ion battery pole piece and manufacturing method thereof

A lithium-ion battery and pole piece technology, which is applied to battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve the problems of affecting production efficiency and time-consuming, so as to reduce the injection speed, reduce side reactions, and fast The effect of absorption speed and liquid retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

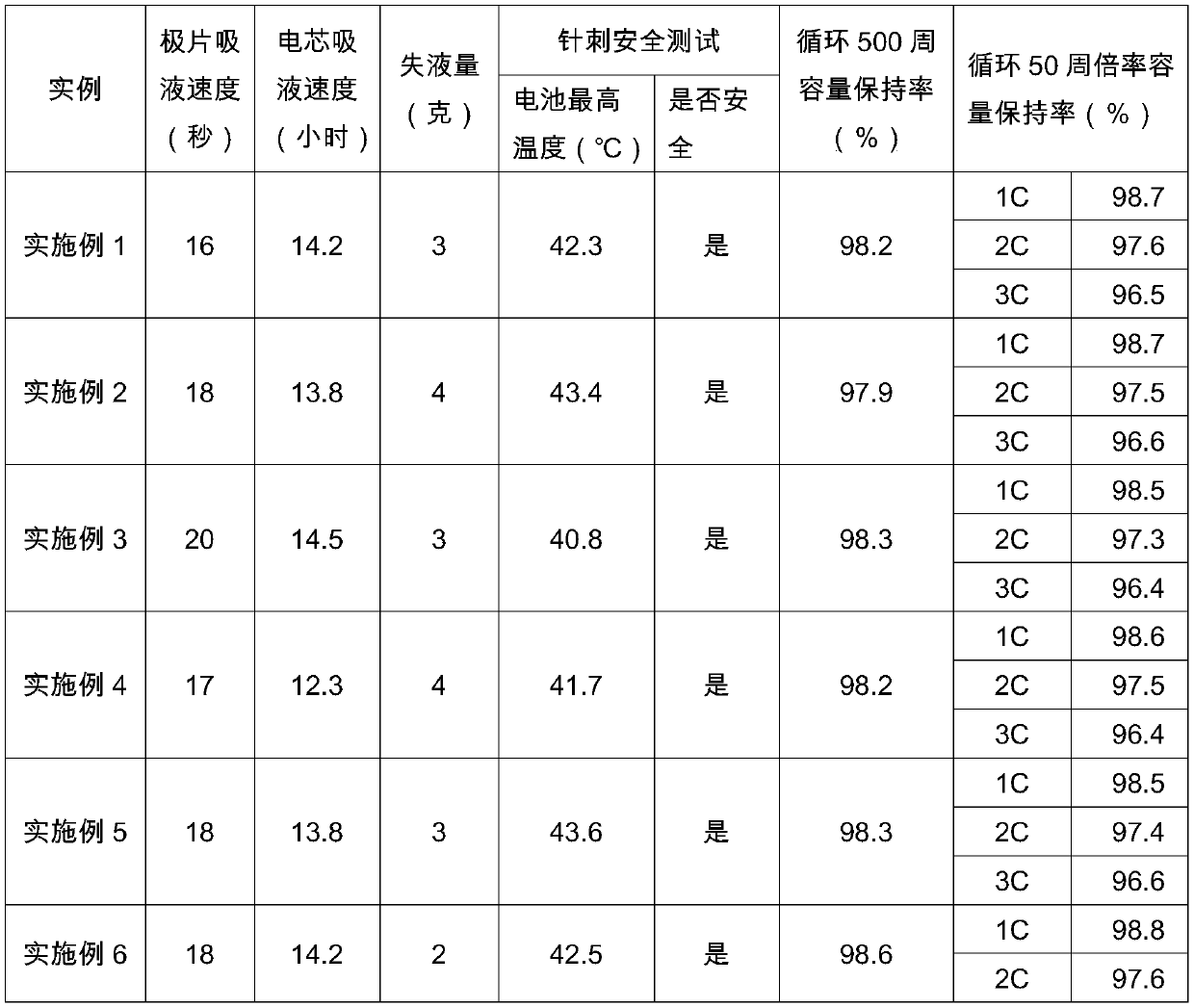

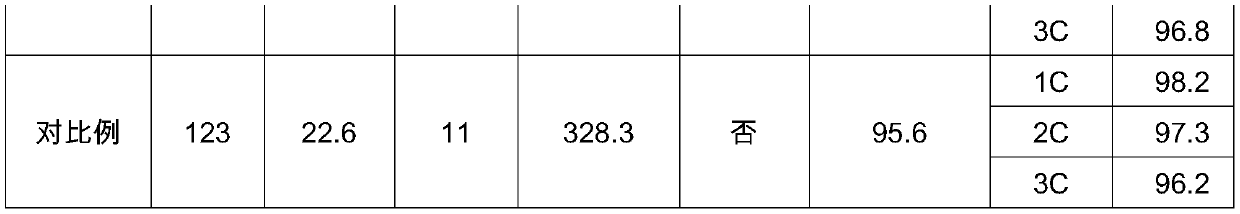

Examples

Embodiment 1

[0020] (1) Preparation of lithium-ion battery positive pole piece

[0021] Active material positive electrode sheet production:

[0022] Lithium iron phosphate, conductive carbon black, binder polyvinylidene fluoride, and N-methylpyrrolidone are mixed uniformly at a mass ratio of 96:2.5:1.5 to make a lithium-ion battery positive electrode slurry, which is coated on the current collector aluminum foil; Dry at 87° C., and then carry out roll-cutting and die-cutting to obtain positive electrode sheets of active materials.

[0023] Apply ceramic coating:

[0024] The lithium metaaluminate ceramic powder with a maximum particle size of 100nm, the binder polyvinylidene fluoride, and the solvent N-methylpyrrolidone are prepared into a ceramic slurry, and the mass parts are: 5 parts of lithium metaaluminate ceramic powder , 1 part of polyvinylidene fluoride, 30 parts of N-methylpyrrolidone; then the prepared ceramic slurry is evenly coated on the positive electrode sheet of the acti...

Embodiment 2

[0048] (1) The same method as in Example 1 was used to prepare the positive electrode sheet of the lithium ion battery active material.

[0049] Apply ceramic coating:

[0050] Lithium metaaluminate ceramic powder, zirconia ceramic powder, binder polyvinylidene fluoride, and solvent N-methylpyrrolidone are formulated into a ceramic slurry, and the parts by mass are: 3 parts of lithium metaaluminate ceramic powder, 2 parts of zirconia ceramic powder, 1 part of polyvinylidene fluoride, 30 parts of N-methylpyrrolidone (wherein the maximum particle size of lithium metaaluminate ceramic powder and zirconia ceramic powder is 100nm); then the prepared The ceramic slurry was uniformly coated on the positive electrode sheet of the active material prepared above, dried, and rolled with a rolling pressure of 1 MPa to obtain the positive electrode sheet of the lithium-ion battery. The thickness of the ceramic coating was 100 μm.

[0051](2) The same method as in Example 1 was used to pre...

Embodiment 3

[0065] (1) The same method as in Example 1 was used to prepare the positive electrode active material pole sheet of the lithium ion battery, except that the positive electrode active material used was lithium cobaltate.

[0066] Apply ceramic coating:

[0067] Lithium metaaluminate ceramic powder, zirconia ceramic powder, binder polyvinylidene fluoride, and solvent N-methylpyrrolidone are formulated into a ceramic slurry, and the parts by mass are: 3 parts of lithium metaaluminate ceramic powder, 2 parts of zirconia ceramic powder, 1 part of polyvinylidene fluoride, 30 parts of N-methylpyrrolidone (wherein the maximum particle diameter of lithium metaaluminate ceramic powder and zirconia ceramic powder is 100 μm); then the prepared The ceramic slurry was uniformly coated on the positive electrode sheet of the active material prepared above, dried, and rolled with a rolling pressure of 0.9 MPa. The thickness of the ceramic coating is 100 μm, and the position of the ceramic coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com