Catalyst for direct preparation of styrene by catalyzing acetylene and its preparation method and application

A catalyst and styrene technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of overcapacity of polyvinyl chloride and low industrial profits, and achieve improved catalyst performance, short process routes, The effect of mild reaction conditions

Active Publication Date: 2022-05-31

ENN SCI & TECH DEV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the main downstream product of acetylene, polyvinyl chloride (PVC), has a serious overcapacity and low industrial profits. It is urgent to expand the industrial chain of downstream products of acetylene.

However, there are no related studies and reports

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

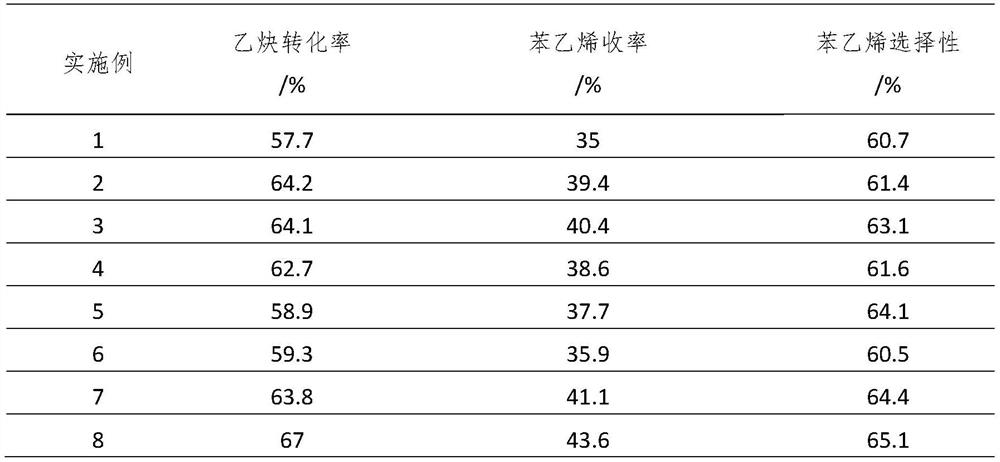

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of catalysts, and specifically discloses a catalyst for directly preparing styrene by catalyzing acetylene, a preparation method and application thereof. The catalyst is a molecular sieve modified by metal and metal oxide, and the metal (niobium, molybdenum, tungsten, zirconium) oxide component of the modified acid site and the metal (palladium, platinum , ruthenium) components are impregnated step by step and confined in the pores of the molecular sieve, the amount of B acid and L acid in the molecular sieve is adjusted by the metal oxide to change the catalytic effect, and at the same time, highly dispersed metal sites are introduced to activate the reactant molecules and stabilize the intermediate species. , to improve catalyst performance. The present invention breaks the traditional technical route of styrene, broadens the downstream products of coal-based acetylene, and synthesizes styrene through the direct reaction of acetylene and benzene under the action of the catalyst. The reaction conditions are mild. Compared with the traditional technical route of styrene, the process route is Short, low energy consumption, obvious technical advantages.

Description

Catalyst for directly preparing styrene from acetylene and its preparation method and application technical field The present invention relates to catalyst technical field, specifically, relate to a kind of catalyst for directly preparing styrene by catalyzing acetylene Chemical agent and preparation method and application thereof. Background technique Styrene, as an important chemical basic raw material, is mainly used in synthetic rubber and resin, and its downstream products mainly include Styrene-butadiene rubber, polystyrene resin, ABS engineering plastics and other products are widely used in industrial applications and are in high demand. At present, styrene is basically Since petrochemical technology, nearly 90% of the production capacity is mainly through ethylbenzene dehydrogenation technology, and its process route first passes through benzene and ethylene The production of ethylbenzene, and then the production of styrene by dehydrogenation of ethylbenzen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J29/48C07C2/38C07C15/46

CPCB01J29/48C07C2/38C07C15/46Y02P20/584

Inventor 杜波王会升赵锐君

Owner ENN SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com