Method for preparing rod-shaped platinum nanoparticles

A platinum nanoparticle and rod-shaped technology, which is applied in the field of preparation of precious metal nanomaterials, can solve problems such as complex operation, difficult acquisition of target products, and difficult growth, and achieve uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

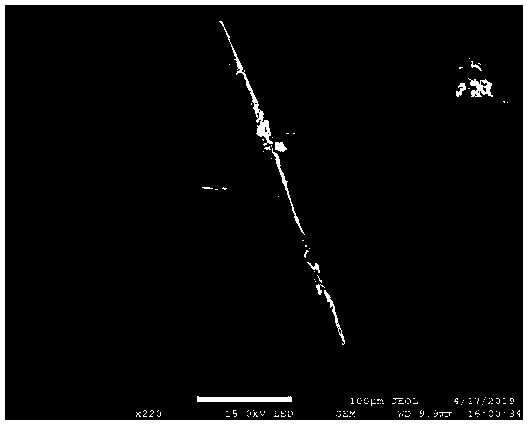

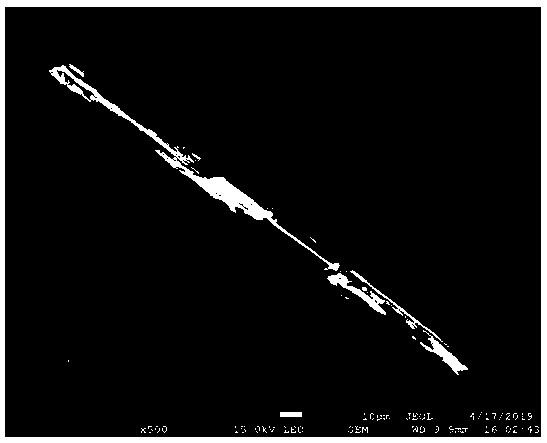

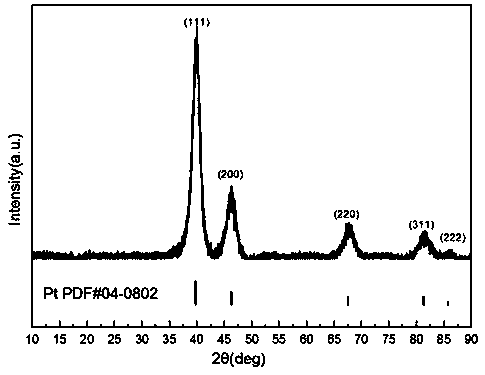

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of preparation method of rod-shaped platinum nanoparticles, the specific steps are as follows:

[0028] (1) Evaporate and crystallize the platinum precursor solution (chloroplatinic acid solution) to obtain platinum precursor crystals; the concentration of the platinum precursor solution (chloroplatinic acid solution) is 0.01mol / L;

[0029] (2) Add the platinum precursor crystal to the surfactant-surfactant and ultrasonically treat it to obtain a platinum precursor-surfactant mixed solution, in which the surfactant is a mixed solution of oleic acid-oleylamine, and a mixed solution of oleic acid-oleylamine The volume ratio of oleic acid to oleylamine in the solution is 3:1, the concentration of platinum precursor in the platinum precursor-surfactant mixed solution is 0.005mol / L; the surface dispersant is polyvinylpyrrolidone, polyvinylpyrrolidone and platinum precursor The molar ratio is 1:20;

[0030] (3) Prepare the reducing agent oleic acid solut...

Embodiment 2

[0034] Embodiment 2: a kind of preparation method of rod-shaped platinum nanoparticles, the specific steps are as follows:

[0035] (1) Evaporate and crystallize the platinum precursor solution (potassium chloroplatinate solution) to obtain platinum precursor crystals; the concentration of the platinum precursor solution (potassium chloroplatinate solution) is 0.1mol / L;

[0036](2) Add the platinum precursor crystal to the surfactant-surfactant and ultrasonically treat it to obtain a platinum precursor-surfactant mixed solution, in which the surfactant is a mixed solution of oleic acid-oleylamine, and a mixed solution of oleic acid-oleylamine The volume ratio of oleic acid to oleylamine in the solution is 4:1, the concentration of platinum precursor in the platinum precursor-surfactant mixed solution is 0.02mol / L; the surface dispersant is polyvinylpyrrolidone, polyvinylpyrrolidone and platinum precursor The molar ratio is 1:10;

[0037] (3) Prepare the reducing agent oleic a...

Embodiment 3

[0040] Embodiment 3: a kind of preparation method of rod-shaped platinum nanoparticles, the specific steps are as follows:

[0041] (1) Evaporate and crystallize the platinum precursor solution (ammonium chloroplatinite solution) to obtain platinum precursor crystals; the concentration of the platinum precursor solution (ammonium chloroplatinite solution) is 0.05mol / L;

[0042] (2) Add the platinum precursor crystal to the surfactant-surfactant and ultrasonically treat it to obtain a platinum precursor-surfactant mixed solution, in which the surfactant is a mixed solution of oleic acid-oleylamine, and a mixed solution of oleic acid-oleylamine The volume ratio of oleic acid and oleylamine in the solution is 5:1, the concentration of platinum precursor in the platinum precursor-surfactant mixed solution is 0.01mol / L; the surface dispersant is polyvinylpyrrolidone, polyvinylpyrrolidone and platinum precursor The molar ratio is 1:15;

[0043] (3) Prepare the reducing agent oleic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com