Method for treating uranium-containing wastewater by using electricity-generating microorganism supported Fe/C nano composite material

A technology of nanocomposite materials and electricity-producing microorganisms, which is applied in the field of hexavalent uranyl, can solve the problem of low uranyl reduction rate, and achieve the effects of improving process efficiency, easy operation, and strong removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

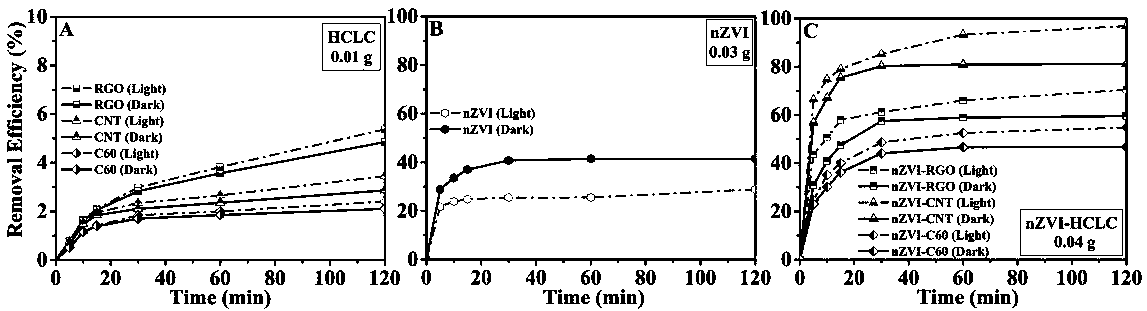

[0056] Under the conditions of pH=5, T=20 ℃, 200 W light and dark conditions, 0.01 g carbon material, 0.03 g nanometer zero-valent iron, 0.04 g Synthetic materials, the relationship between the removal efficiency of uranium and the time change is shown in the appendix figure 1 . By comparison, it is found that the removal rate R of synthetic materials under light conditions is very high compared to that of individual materials [for example, R (96.87%, nZVI-CNT, Light, 0.04 g) > R (81.16%, nZVI-CNT, Dark , 0.04g) > R (41.45%, nZVI, Dark, 0.03 g ) + R (2.86%, CNT, Dark, 0.01 g)], and the advantage of nZVI-CNT among the three synthetic materials is more obvious [R (96.87% , nZVI-CNT, Light, 4 mg) > R (70.41%, nZVI-RGO, Light, 4 mg) > R (54.81%, nZVI-C60, Light, 3 mg )], so carbon nanotubes and nanozero The binding material of valent iron is more suitable.

Embodiment 2

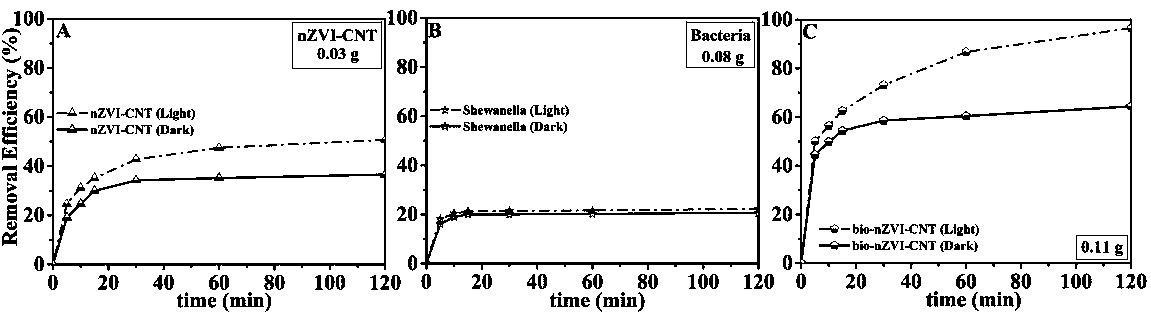

[0058] Under pH=5, T=20 ℃, 200 W light and dark conditions, 0.03 g nZVI-CNT, 0.08 g Shewanella, and 0.11 g bio-nZVI-CNT material. The relationship of the removal efficiency of uranium with time is shown in the appendix figure 2 . Through comparison, it is found that the combination of synthetic material nZVI-CNT and Shewanella under light conditions can further improve the effect of individual materials [R(97.11%, bio-nZVI-CNT, Light, 0.11 g) > R(64.40% ,bio-nZVI-CNT, Dark, 0.11 g) > R(36.56%, nZVI-CNT, Dark, 0.03 g) + R(22.24%,S. Putrefaciens, Dark, 0.08 g)], so the composite with Khiva Bacteria combination has a synergistic effect.

Embodiment 3

[0060] Under the conditions of pH=5, T=20°C, and light of 200W, put sodium chloride particles into six groups of water containing 1L uranium containing 50mg / L uranium, so that the concentration reaches 0.01 mol / L, 0.05 mol / L, 0.1 mol / L, and then put in 0.03nZVI-CNT and 0.11g bio-nZVI-CNT materials respectively. The relationship between the removal efficiency of uranium as a function of time and the ionic strength are shown in the appendix image 3 A and B. By comparison, it is found that the higher the ionic strength, the greater the impact on bio-nZVI-CNT (the removal rate of uranium decreases with the increase of ionic strength), but the ionic strength has almost no effect on the removal efficiency of nZVI-CNT, indicating that the appropriate Reducing the ionic strength can improve the removal efficiency of bio-nZVI-CNT materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com