Preparation method of micronutrient element zinc-manganese chelate

A technology of micronutrient and elemental zinc, which is applied in the field of preparation of zinc-manganese chelates, achieves the effect of simple method and increased content ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

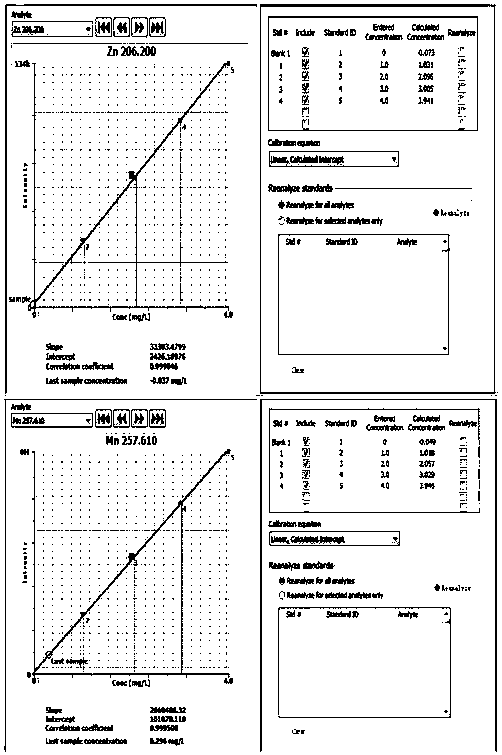

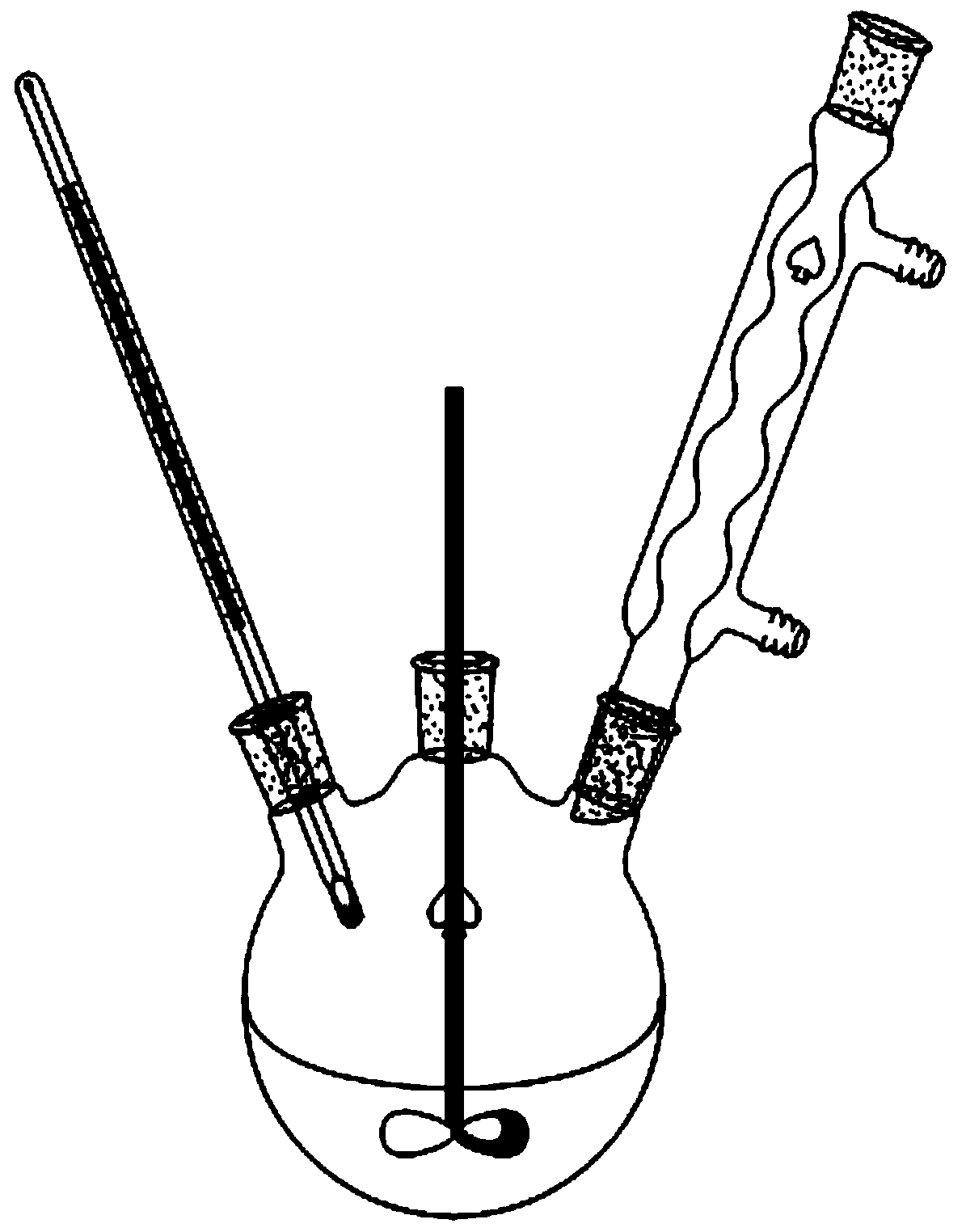

Method used

Image

Examples

Embodiment 1

[0038] 1) Preparation of aqueous solution of glucoheptononic acid

[0039] Solid sodium glucoheptonate (Wuhan Yuancheng Science and Technology Development Co., Ltd. industrial grade) was formulated into an aqueous solution, and the activated large-pore strong acid cation exchange resin (Shanghai Jinkai Resin Co., Ltd. D301) carried out ion exchange to obtain a mass percentage of 10% aqueous solution of glucoheptonic acid.

[0040] 2) Preparation of zinc hydroxide or manganese hydroxide

[0041] Preparation of zinc hydroxide: Stir saturated zinc sulfate solution, and dropwise add 0.2M sodium bicarbonate solution at the same time, stop dropping when white precipitate appears at pH 7.5-8; stop stirring and stand still for 24 hours; filter, wash, pump Just dry.

[0042] Preparation of manganese hydroxide: Stir the saturated manganese sulfate solution, and add dropwise a 0.2M sodium bicarbonate solution at the same time, stop the dropwise addition when a brown precipitate appears...

Embodiment 2

[0046] 1) Preparation of aqueous solution of glucoheptononic acid

[0047] Solid sodium glucoheptonate (Wuhan Yuancheng Science and Technology Development Co., Ltd. industrial grade) was formulated into an aqueous solution, and the activated large-pore strong acid cation exchange resin (Shanghai Jinkai Resin Co., Ltd. D301) carried out ion exchange to obtain a mass percentage of 20% aqueous solution of glucoheptonic acid.

[0048] 2) Preparation of zinc hydroxide or manganese hydroxide

[0049] Preparation of zinc hydroxide: Stir saturated zinc sulfate solution, and dropwise add 0.2M sodium bicarbonate solution at the same time, stop dropping when white precipitate appears at pH 7.5-8; stop stirring and stand still for 24 hours; filter, wash, pump Just dry.

[0050]Preparation of manganese hydroxide: Stir saturated manganese sulfate solution, and dropwise add 0.2M sodium bicarbonate solution at the same time, stop the dropwise addition when a brown precipitate appears above ...

Embodiment 3

[0054] 1) Preparation of aqueous solution of glucoheptononic acid

[0055] Solid sodium glucoheptonate (Wuhan Yuancheng Science and Technology Development Co., Ltd. industrial grade) was formulated into an aqueous solution, and the activated large-pore strong acid cation exchange resin (Shanghai Jinkai Resin Co., Ltd. D301) carried out ion exchange to obtain a mass percentage of 30% aqueous solution of glucoheptonic acid.

[0056] 2) Preparation of zinc hydroxide or manganese hydroxide

[0057] Preparation of zinc hydroxide: Stir saturated zinc sulfate solution, and dropwise add 0.2M sodium bicarbonate solution at the same time, stop dropping when white precipitate appears at pH 7.5-8; stop stirring and stand still for 24 hours; filter, wash, pump Just dry.

[0058] Preparation of manganese hydroxide: Stir saturated manganese sulfate solution, and dropwise add 0.2M sodium bicarbonate solution at the same time, stop the dropwise addition when a brown precipitate appears above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com