Anti-freezing pavement sealing layer material and preparation method thereof

An anti-ice, layer material technology, used in coatings, anti-corrosion coatings, asphalt coatings, etc., can solve the problems affecting the durability of asphalt mixture, high energy consumption, environmental damage, etc., to improve the anti-ice performance and anti- Slippery, improve hydrophobicity, prevent water damage to pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of anti-icing pavement sealing material, in parts by weight, is made of the following raw materials: emulsified asphalt is 57%, filler is 5.4%, mixed solution is 15.2%, organosilicon polyacrylic resin is 22.4%;

[0035] The filler is made of the following raw materials: 65.3% zinc oxide, 19.8% zirconium dioxide, 14.9% ferric chloride;

[0036] The mixed solution is made from the following raw materials: 33.3% of acetylacetone, 16.7% of butyl acetate, and 50% of cyclohexane.

[0037] The preparation method of the anti-icing pavement sealing material of the present embodiment, the method specifically comprises the following steps:

[0038] Step 1: After weighing zinc oxide, zirconium dioxide and ferric chloride, add them to a planetary ball mill in turn, mill for 2 hours, take them out and calcinate them in a muffle furnace at 600°C for 1 hour, then take them out and rinse them with distilled water, and take out the precipitate for ...

Embodiment 2

[0043] The present embodiment provides a kind of anti-icing pavement sealing material, in parts by weight, is made of the following raw materials: emulsified asphalt is 59.8%, filler is 5.4%, mixed solution is 12.4%, organosilicon polyacrylic resin is 22.4%;

[0044] The filler is made of the following raw materials: 73.7% zinc oxide, 21.1% zirconium dioxide, 5.2% ferric chloride;

[0045] The mixed solution is made from the following raw materials: 33.3% of acetylacetone, 16.7% of butyl acetate, and 50% of cyclohexane.

[0046] The preparation method of the anti-icing pavement sealing material of this embodiment is the same as that of Embodiment 1.

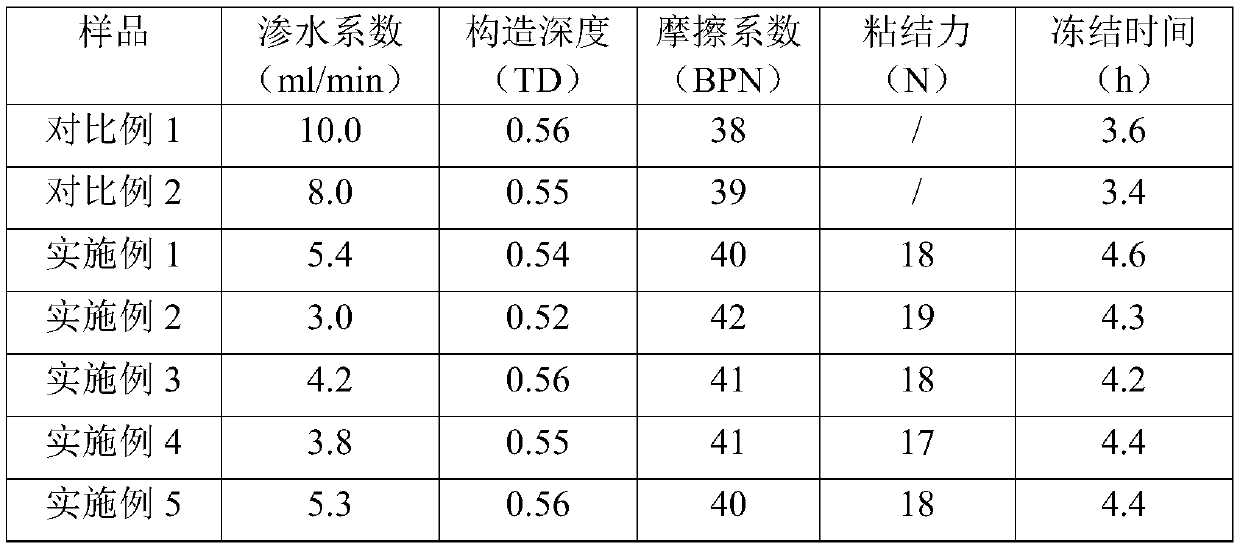

[0047] See Table 1 for the test results of the asphalt pavement performance of the anti-icing pavement sealing material of this embodiment.

Embodiment 3

[0049] The present embodiment provides a kind of anti-icing pavement sealing material, is made of the following raw materials in parts by weight: emulsified asphalt is 56.2%, filler is 6.2%, mixed solution is 11%, organosilicon polyacrylic resin is 26.6%;

[0050] The filler is made of the following raw materials: 69.1% zinc oxide, 21.8% zirconium dioxide, 9.1% ferric chloride;

[0051]The mixed solution is made from the following raw materials: 33.3% of acetylacetone, 16.7% of butyl acetate, and 50% of cyclohexane.

[0052] The preparation method of the anti-icing pavement sealing material of this embodiment is the same as that of Embodiment 1.

[0053] See Table 1 for the test results of the asphalt pavement performance of the anti-icing pavement sealing material of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com