Photo-thermal dual-curing engineering adhesive, and preparation method and application thereof

A dual-curing, adhesive technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of incomplete curing of glue, poor mechanical properties, bonding failure, etc., to solve the application limitations of bonding, Ease of industrial production and the effect of solving absorption problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

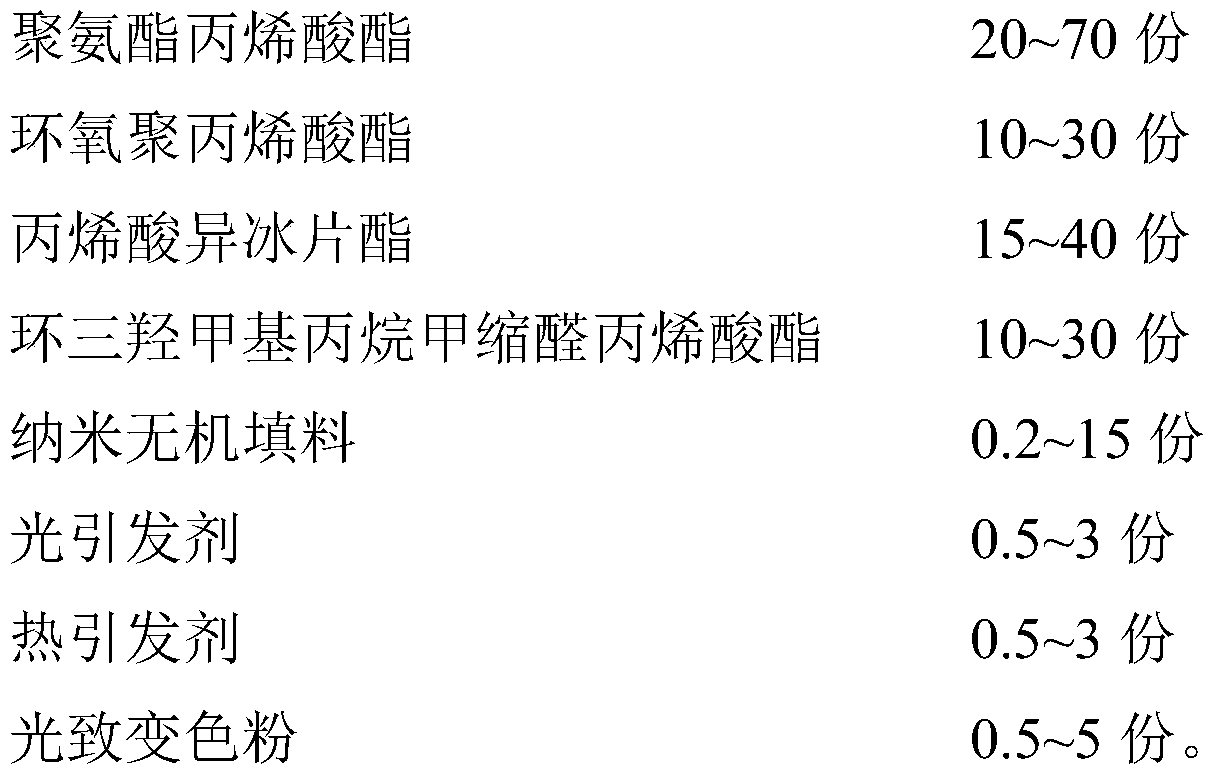

[0028] A light-heat dual-curable engineering adhesive is made of the following components by weight:

[0029]

[0030] The light gray photochromic powder is a commercially available microcapsule powder that undergoes a colorless to light gray reversible color change with the irradiation of ultraviolet wavelengths. Prepared.

[0031] A preparation method of a photothermal dual-curable engineering adhesive, the method comprising:

[0032] Stir polyurethane acrylate, epoxy polyacrylate, isobornyl acrylate, cyclotrimethylolpropane methylal acrylate, photoinitiator TPO and azobisisoheptanonitrile in a light-tight container, and stir The speed is 300r / min, stirring for 30min to obtain a mixed liquid;

[0033] Slowly add light gray photochromic powder into the mixed liquid while stirring, stir and mix, the stirring speed is 200r / min, stir for 30min, then slowly add nano silicon dioxide, ultrasonic for 20min, after vacuum defoaming to obtain photothermal dual curing engineering ...

Embodiment 2

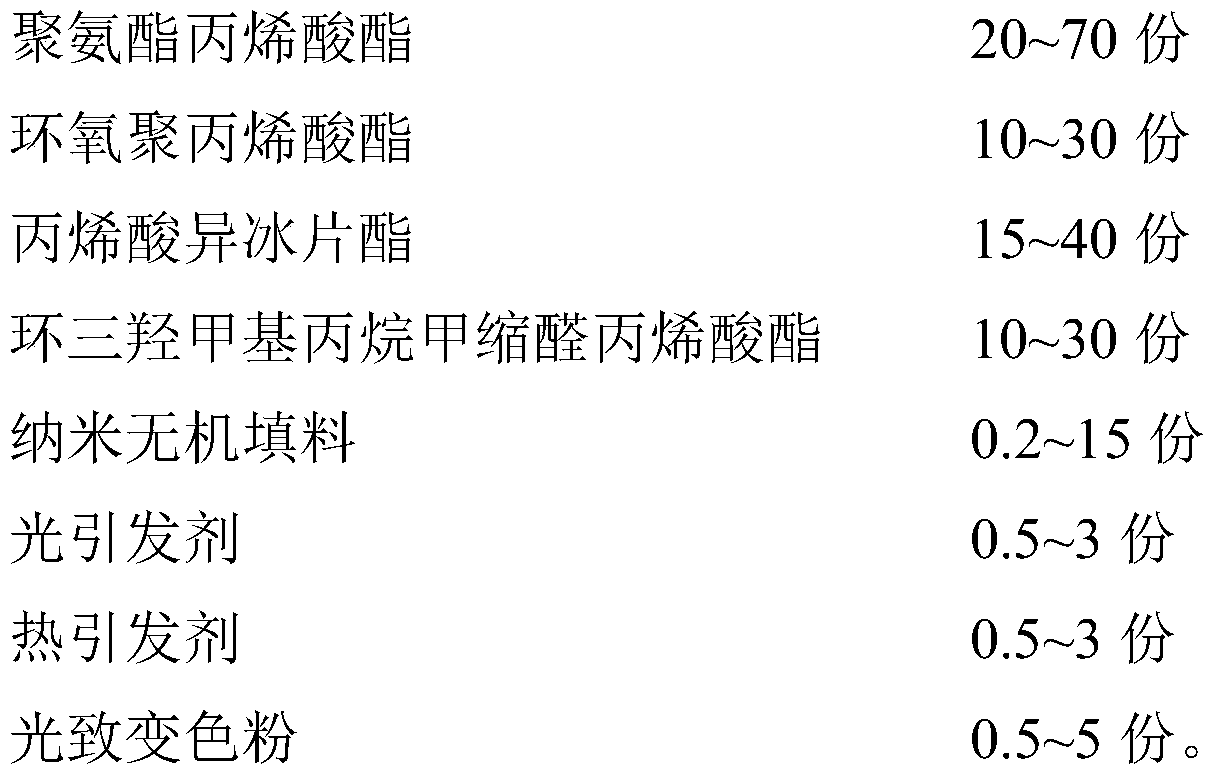

[0037] A light-heat dual-curable engineering adhesive is made of the following components by weight:

[0038]

[0039] The red photochromic powder is prepared from a commercially available microcapsule powder that undergoes a reversible color change from colorless to red when irradiated by ultraviolet wavelengths. It is prepared after ultrasonic treatment with 86% ethanol solvent for 18 minutes and spray drying for 2 hours. .

[0040] A preparation method of a photothermal dual-curable engineering adhesive, the method comprising:

[0041] Stir and mix polyurethane acrylate, epoxy polyacrylate, isobornyl acrylate, cyclotrimethylolpropane formal acrylate, photoinitiator 819 and ethylenediamine in a light-tight container at a stirring speed of 200r / min, stirred for 40min to obtain mixed liquid;

[0042]Slowly add red photochromic powder into the mixed liquid while stirring, stir and mix, the stirring speed is 300r / min, stir for 25min, then slowly add nano-alumina, ultrasoni...

Embodiment 3

[0046] A light-heat dual-curable engineering adhesive is made of the following components by weight:

[0047]

[0048] The blue photochromic powder is prepared from a commercially available microcapsule powder that undergoes a reversible color change from colorless to blue when irradiated with ultraviolet wavelengths, and is prepared after ultrasonic treatment with 90% mass concentration of ethanol solvent for 20 minutes and spray drying for 1.8 hours. made.

[0049] A preparation method of a photothermal dual-curable engineering adhesive, the method comprising:

[0050] Stir and mix polyurethane acrylate, epoxy polyacrylate, isobornyl acrylate, cyclotrimethylolpropane formal acrylate, photoinitiator TPO-L and aromatic amine in a light-tight container at a stirring speed of 250r / min, stirring for 40min to obtain a mixed liquid;

[0051] Slowly add blue photochromic powder into the mixed liquid while stirring, stir and mix, the stirring speed is 270r / min, stir for 25min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com