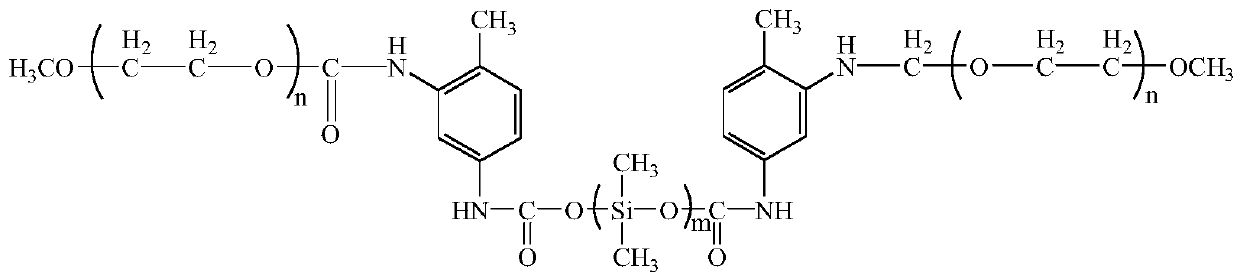

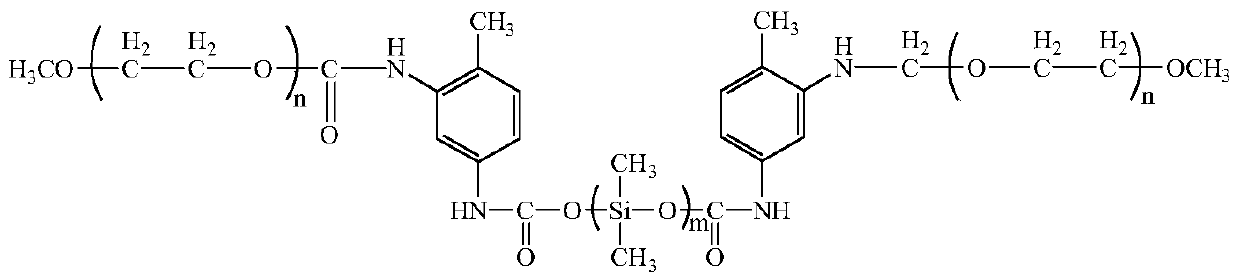

High-efficiency water-soluble viscosity-reducing oil-washing agent for heavy oil thermal recovery and preparation method of oil-washing agent

A technology for thermal recovery of heavy oil and oil washing agent, which is applied in the field of chemical agents, can solve the problems of no obvious effect and weak recovery rate, and achieves the effects of wide source of raw materials, easy acquisition, transportation and storage, and clean and pollution-free process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

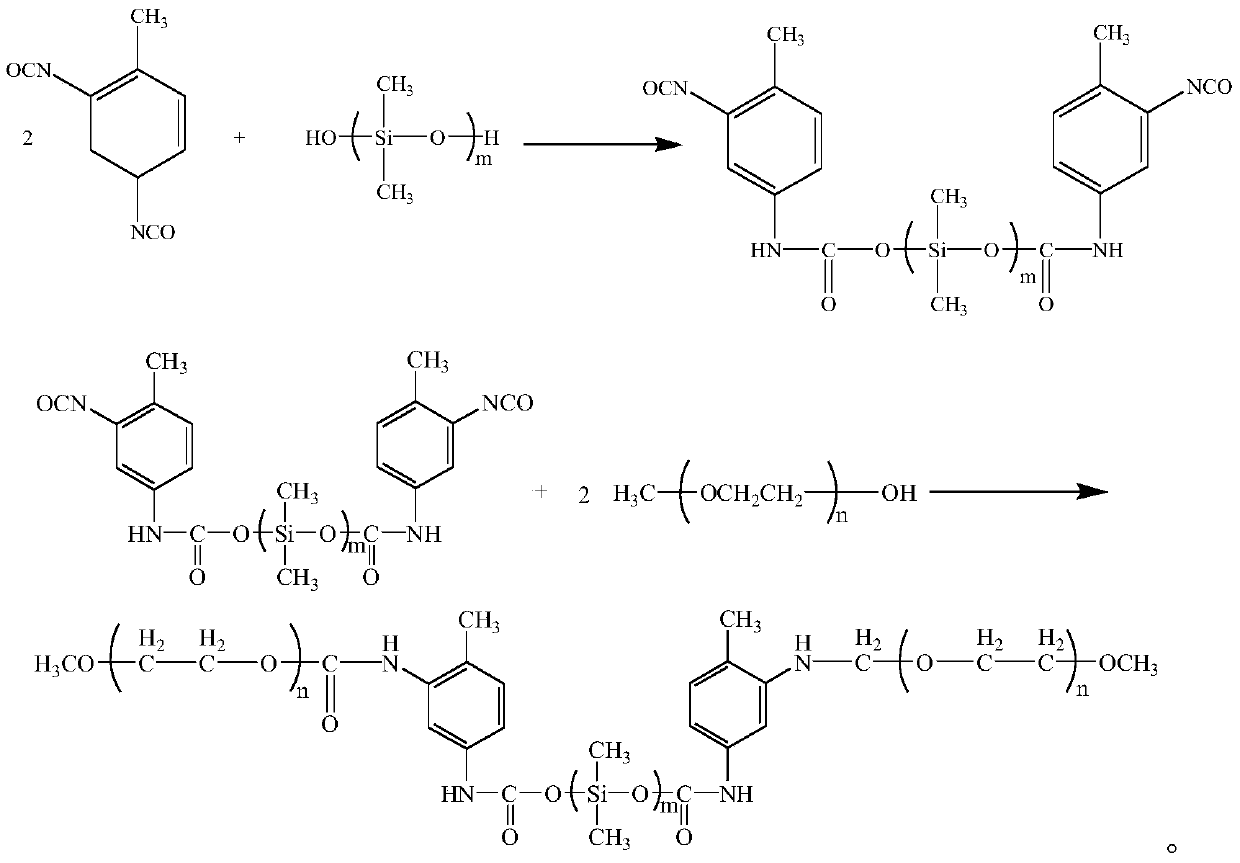

[0025] (1) Add 1mol toluene diisocyanate, 0.4mol polymethylsiloxane (7) and 1219.05g solvent water into a four-neck flask with a thermometer, reflux condenser and stirrer, heat while stirring, and the stirring rate The heating temperature is 400rpm, the heating temperature is 30°C, nitrogen gas is introduced, and the ventilation time is 3min. Next, 0.88g of the catalyst dibutyltin laurate is slowly added to the four-necked flask, and nitrogen gas is continued to be introduced, and the heating temperature of the four-necked flask is raised to 80 °C, the stirring rate was adjusted to 500 rpm, the reaction was continued for 4 h, and then the temperature was lowered to room temperature to obtain an intermediate mixture.

[0026] (2) Add 1.0mol polyoxyethylene ether (4) to the above intermediate mixture, adjust the stirring rate to 500rpm, adjust the temperature to 75°C, mix well, react for 2h, and cool down to 25°C to obtain the final product mixed liquid.

[0027] (3) Use a rota...

Embodiment 2

[0031] (1) Add 1mol toluene diisocyanate, 0.45mol polymethylsiloxane (9) and 1741.5g solvent water into a four-neck flask with a thermometer, reflux condenser and stirrer, heat while stirring, and the stirring rate The heating temperature is 500rpm, the heating temperature is 45°C, nitrogen gas is introduced, and the ventilation time is 5min. Next, 1.74g of the catalyst dibutyltin laurate is slowly added to the four-necked flask, and nitrogen gas is continued to be introduced, and the heating temperature of the four-necked flask is raised to 85 °C, the stirring rate was adjusted to 550 rpm, the reaction was continued for 5 h, and then the temperature was lowered to room temperature to obtain an intermediate mixture.

[0032] (2) Add 1.05mol of polyoxyethylene ether (6) to the above-mentioned intermediate mixture, adjust the stirring speed to 560rpm, adjust the temperature to 85°C, mix well, react for 3h, and cool down to 28°C to obtain the final product mixed liquid.

[0033]...

Embodiment 3

[0037] (1) Add 1mol toluene diisocyanate, 0.5mol polymethylsiloxane (12) and 2089.8g solvent water into a four-necked flask with a thermometer, a reflux condenser and a stirrer, and heat while stirring. The heating temperature is 550rpm, the heating temperature is 60°C, nitrogen gas is introduced, and the ventilation time is 7min. Next, 2.08g of the catalyst dibutyltin laurate is slowly added to the four-necked flask, and nitrogen gas is continued to be introduced, and the heating temperature of the four-necked flask is raised to 95 °C, the stirring rate was adjusted to 600 rpm, the reaction was continued for 5 h, and then the temperature was lowered to room temperature to obtain an intermediate mixture.

[0038] (2) Add 1.2mol of polyoxyethylene ether (8) to the above-mentioned intermediate mixture, adjust the stirring rate to 600rpm, adjust the temperature to 90°C, mix well, react for 4h, and cool down to 30°C to obtain the final product mixed liquid.

[0039] (3) Use a rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com