Composite metal lithium negative electrode, preparation method and metal lithium battery

A technology of composite metal and lithium negative electrode, which is applied in the direction of lithium battery, battery electrode, electrode carrier/current collector, etc., to reduce the average current density, prolong the cycle life, and alleviate the volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 0.75g of polyvinylpyrrolidone (K30) and 2.5mL of concentrated hydrochloric acid into 30mL of methanol, and stir well. Immerse foamed nickel in the above solution, ultrasonicate for 30min, wash with water and methanol, and set aside. Add 1.2g of zinc nitrate hexahydrate and 1g of 2-methylimidazole into 30mL of methanol, stir to dissolve. Immerse the pretreated nickel foam in the above solution, let it stand at room temperature for 6h, wash it with methanol, and let it dry naturally. The coated nickel foam was calcined in an argon atmosphere at 600°C for 3h with a heating rate of 5°C / min.

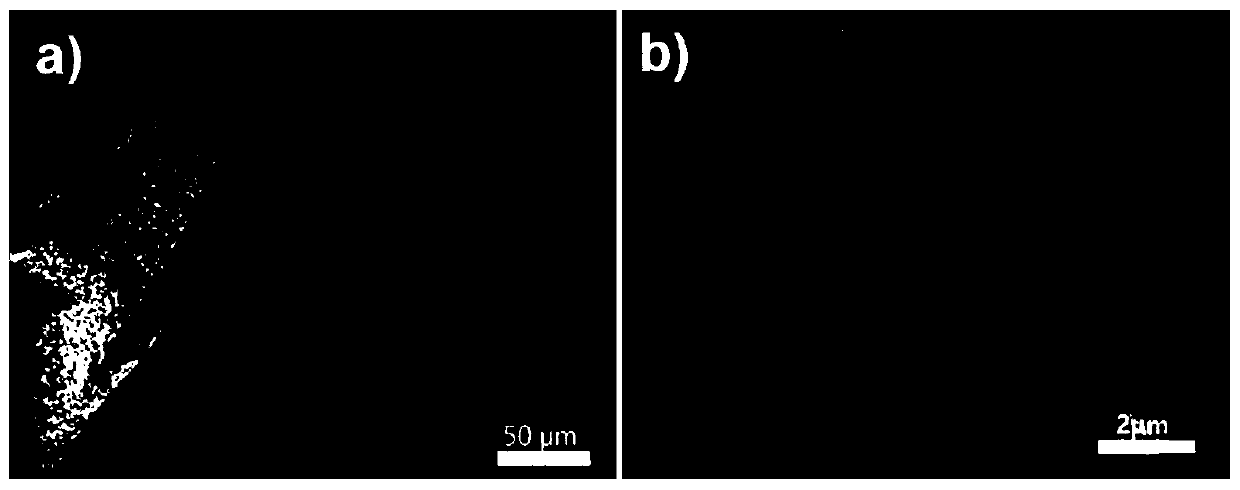

[0039] The scanning electron micrographs of the composite base material prepared above are as follows: figure 1 shown. It can be seen that the coating layer is well dispersed on the three-dimensional current collector framework, and the particle size is uniform.

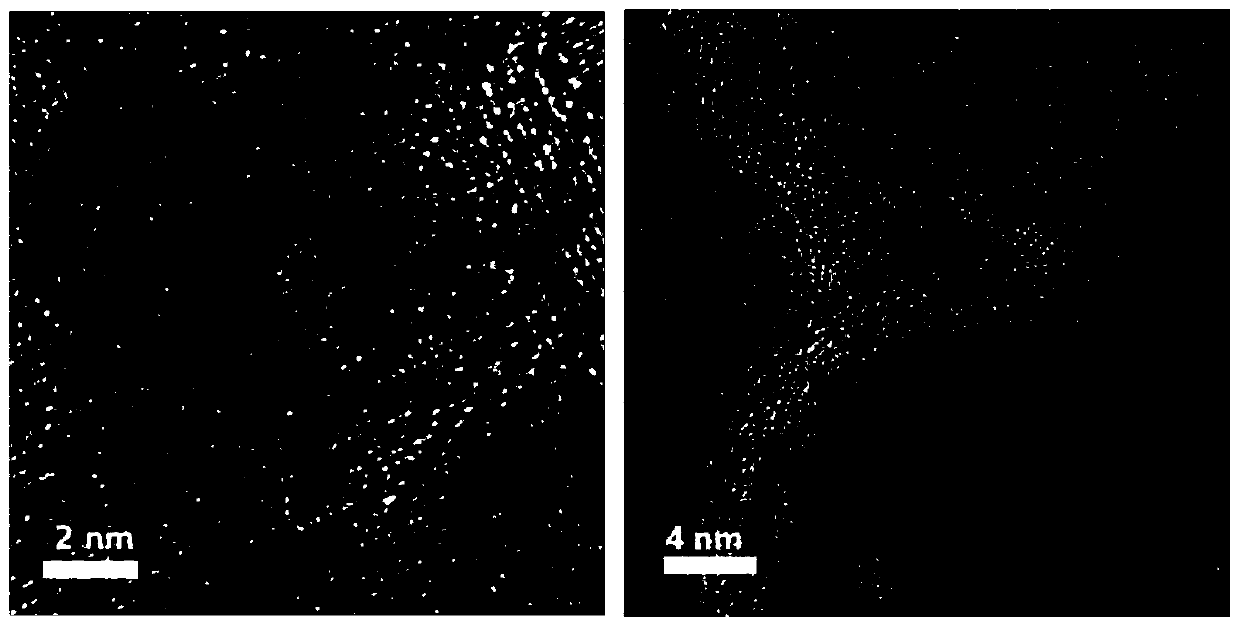

[0040] The transmission electron micrograph of the cladding layer of the composite substrate material prepared abov...

Embodiment 2

[0045] Add 0.75g of polyvinylpyrrolidone (K30) and 2.5mL of concentrated hydrochloric acid into 30mL of methanol, and stir well. Immerse foamed nickel in the above solution, ultrasonicate for 30min, wash with water and methanol, and set aside. Add 1.2g of cobalt nitrate hexahydrate and 1g of adipic acid into 30mL of methanol and stir to dissolve. Immerse the pretreated nickel foam in the above solution, let it stand at room temperature for 6h, wash it with methanol, and let it dry naturally. The coated nickel foam was calcined in an argon atmosphere at 600°C for 3h with a heating rate of 5°C / min.

[0046] The above-mentioned covered and calcined foamed nickel is used as the positive electrode, and the metal lithium sheet is used as the negative electrode to assemble a half-cell, and the metal lithium is deposited on the substrate by an electrochemical deposition method. The electrolyte of the battery is a solution of ethylene glycol dimethyl ether and 1,3-dioxolane (volume r...

Embodiment 3

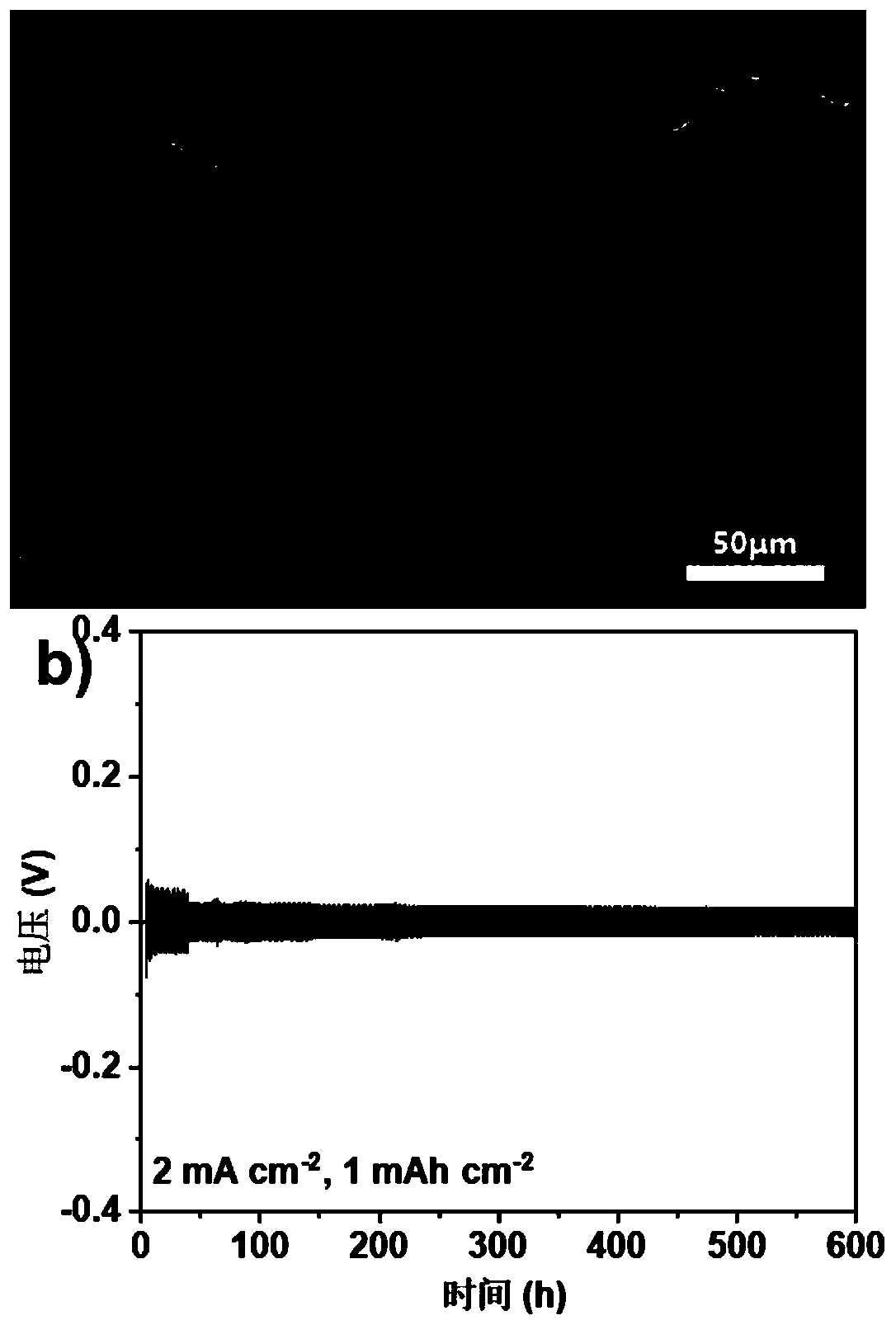

[0048] Following Example 1, only 2-methylimidazole was replaced by terephthalic acid. Deposit two sheets of 10mAh / cm 2 The composite lithium negative pole of metal lithium is assembled into symmetrical battery as the two poles of battery, and battery electrolyte is the ethylene glycol dimethyl ether containing 1mol / L lithium trifluoromethanesulfonylimide and 1,3-dioxolane (volume ratio 1:1) solution. The charge-discharge cycle test is carried out at a current density of 2mA / cm2, and the amount of lithium cycled is 1mAh / cm2 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com