Molybdenum multi-metal sulfide ore flotation separation inhibitor and flotation separation method thereof

A technology for sulfide ores and polymetals, applied in flotation, solid separation and other directions, can solve the problems of poor inhibition effect of organic inhibitors, serious environmental pollution, high toxicity, etc., and achieve the effects of safe use, simple preparation process and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 of the present invention discloses a molybdenum polymetallic sulfide ore flotation separation inhibitor and a flotation separation method thereof, and the adopted technical scheme is as follows:

[0037] Put 6.39g of acrylamide (0.09mol) and 1.16g of allylthiourea (0.01mol) into a 100ml three-necked flask, add 50ml of tetrahydrofuran, stir to make it fully dissolve, and then slowly dropwise add 0.08g of azobisisobutyl Nitrile tetrahydrofuran solution 10ml, control the reaction temperature is 60 ~ 70 ℃, the reaction time is 5 hours, filter and dry to obtain polyacrylamide-allylthiourea polymer, the yield is 98.5%, which is the embodiment of the present invention 1 Molybdenum polymetallic sulfide ore flotation separation inhibitor provided.

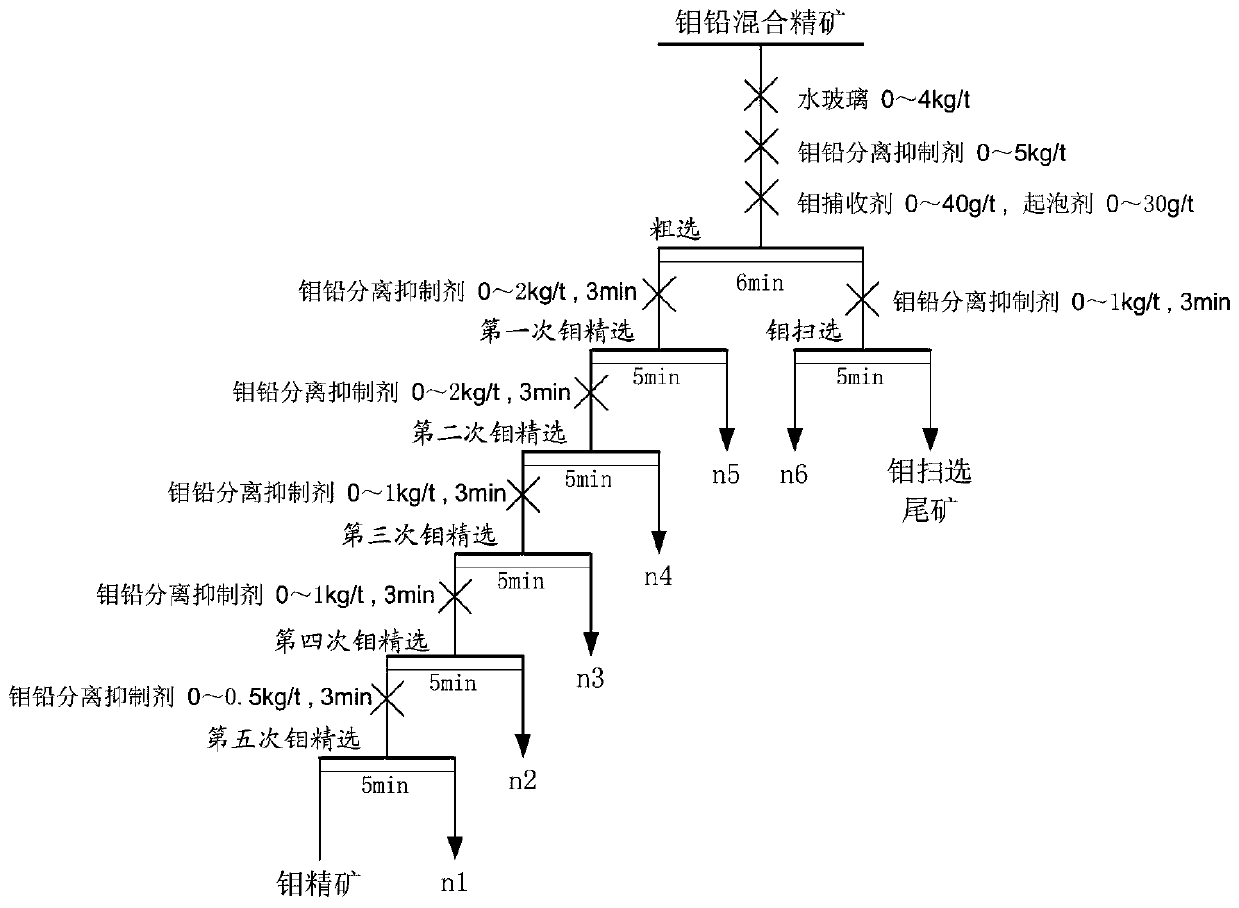

[0038] The molybdenum polymetallic sulfide ore flotation separation inhibitor provided by the embodiment of the present invention 1 is used to carry out the separation test of molybdenum polymetallic mixed concentrate: t...

Embodiment 2

[0042] Embodiment 2 of the present invention discloses a molybdenum polymetallic sulfide ore flotation separation inhibitor and a flotation separation method thereof. The adopted technical scheme is as follows:

[0043] Put 4.97g of acrylamide (0.07mol) and 3.48g of allylthiourea (0.03mol) into a 100ml three-necked flask, add 50ml of tetrahydrofuran, stir to dissolve it fully, and then slowly dropwise add 0.08g of azobisisobutyl Nitrile tetrahydrofuran solution 10ml, control the reaction temperature is 60 ~ 70 ℃, the reaction time is 5 hours, filter and dry to obtain polyacrylamide-allylthiourea polymer, the yield is 95.6%, which is the embodiment of the present invention 1 Molybdenum polymetallic sulfide ore flotation separation inhibitor provided.

[0044] Utilize the molybdenum polymetallic sulfide ore flotation separation inhibitor provided by the embodiment 2 of the present invention to carry out the molybdenum-lead mixed concentrate separation test: the raw material is t...

Embodiment 3

[0047] Embodiment 3 of the present invention discloses a molybdenum polymetallic sulfide ore flotation separation inhibitor and a flotation separation method thereof, and the adopted technical scheme is as follows:

[0048] Put 6.04g of acrylamide (0.085mol) and 1.74g of allylthiourea (0.015mol) into a 100ml three-necked flask, add 50ml of tetrahydrofuran, stir to make it fully dissolve, and then slowly dropwise add 0.08g of azobisisobutyl Nitrile tetrahydrofuran solution 10ml, control the reaction temperature is 60 ~ 70 ℃, the reaction time is 5 hours, filter and dry to obtain polyacrylamide-allylthiourea polymer, the yield is 97.6%, which is the embodiment of the present invention 3 Molybdenum polymetallic sulfide ore flotation separation inhibitor provided.

[0049] Utilize the molybdenum polymetallic sulfide ore flotation separation inhibitor provided by the embodiment of the present invention 3 to carry out molybdenum-lead and copper-molybdenum pure mineral artificial mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com